Editor’s note

As of March 2023, the Callaway County MU Extension office no longer has a breeding barn.

One of the challenges producers cite in implementing an artificial insemination (AI) program is access to functional facilities. Facilities can make working cattle a breeze or a burden depending on design and use. Time, labor needed, exposure to the elements, and ease of cattle movement are all concerns when considering facilities for an AI program. Breeding large numbers of cattle can be a hardship if cattle do not move quickly and calmly through the system. With well-designed and properly used facilities, cattle will flow smoothly through a chute or breeding barn, reducing the overall time spent to inseminate a herd.

Protection from the elements

When implementing an AI program, protection from extreme weather is an important consideration. When using a timed AI protocol, cows cannot simply be bred on a different day due to rain or snow. Sperm are very sensitive to temperature shock, water, and light. Therefore, sperm viability can be greatly reduced if semen is exposed to the elements during the catheter preparation and AI process. Providing cover from the elements for the person thawing as well as the inseminator, can mitigate some issues with sperm viability if weather is not ideal. Using a carport or barn to cover the chute is an option to limit the impacts of weather on the semen. Thawing semen in an enclosed space like a breeding lab or shed is an option to control the temperature as well as avoid exposure of the semen to light, dust, and rain. In addition, having a covered handling system and working cattle in the early morning during breeding seasons in the warmer months can mitigate reduced pregnancy rates due to heat stress.

Chute and headgate

Artificial insemination can also be safely performed in a standard chute or in a headgate and alley setup, with some considerations. A squeeze chute is preferred to limit movement of cattle during the AI process (Figure 1), although this is not always necessary. Because heifers may be less acclimated to facilities and to human interaction that mature cows, heifers may be more likely to move during the AI process. For this reason, technicians often prefer squeeze chutes or a narrower alley width when artificially inseminating heifers.

When AI is performed in a chute, a palpation cage is preferred rather than attempting to perform AI through a side opening of the chute. Inexperienced technicians often struggle to perform AI through the side of the chute rather than from directly behind the animal, and this positioning through the side of the chute is also more likely to result in shoulder injury if the animal backs out of the headgate. Additionally, placing a bar or chain behind the animal as an additional safety precaution is encouraged, as this limits chances of being kicked or backed into by the animal.

Low-stress handling and facility design

Low-stress animal handling should be a priority at all times and carefully monitored during any AI program. Personnel handling cattle should be aware that animal stress up to and around the time of AI can detrimentally impact pregnancy rates. If extra labor is brought on for animal handling on the day of AI, care should be taken to make sure that all personnel are aware of the stockmanship expectations of the farm or ranch.

Low-stress animal movement should be a priority not only in the facilities leading up to the chute or the breeding barn, but also when cattle are first gathered out of pasture or pens. Handling of animals prior to AI can dramatically influence their willingness to stand calmly during the AI process. Overcrowding tubs or pens, using electric cattle prods, and yelling or making other loud noises are strongly discouraged.

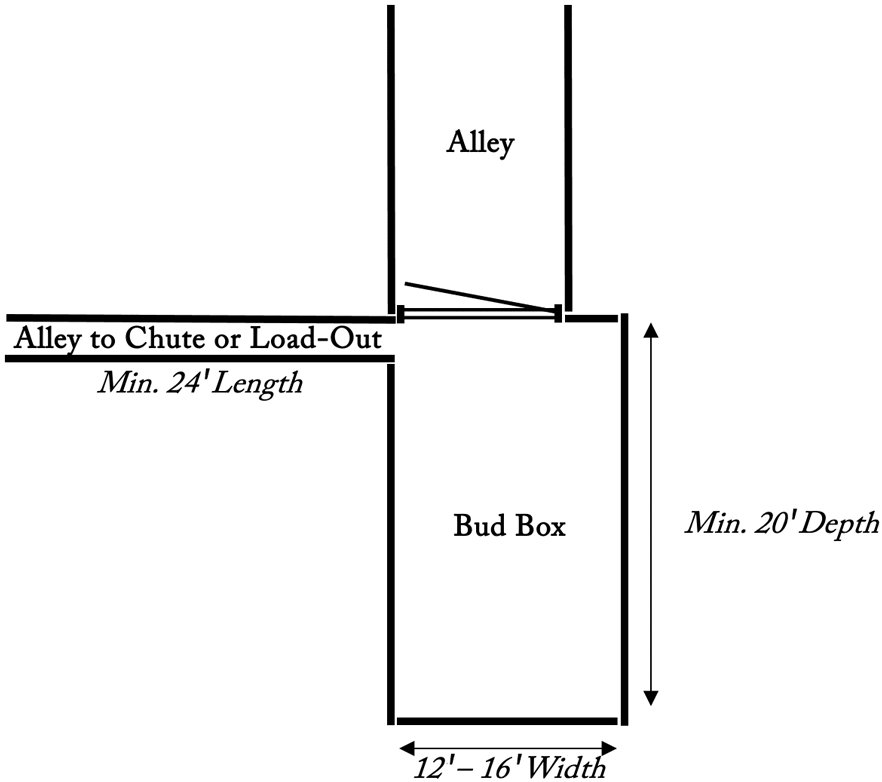

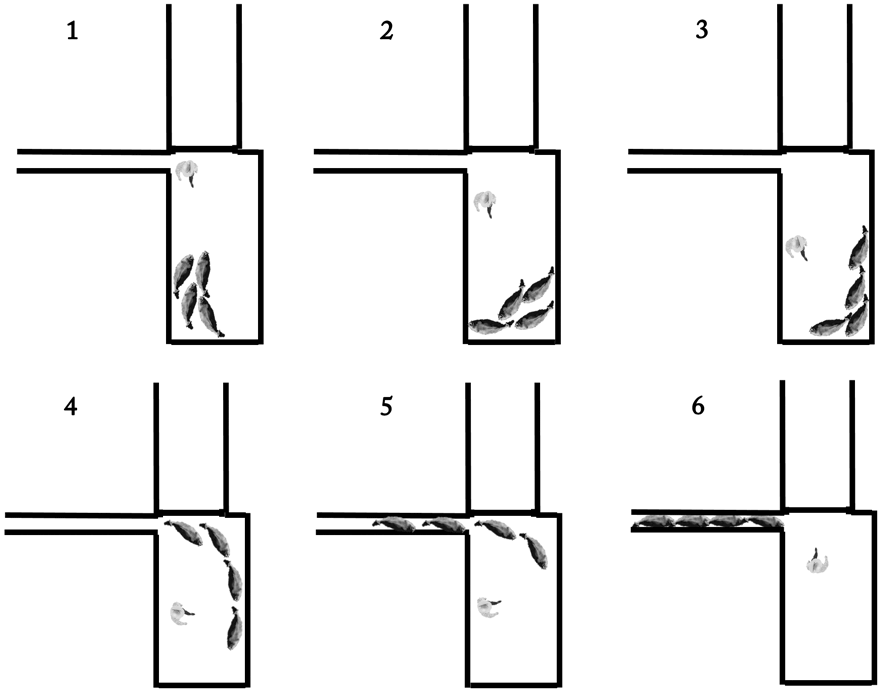

Well-designed and properly used facilities reduce stress on cattle. Low-stress animal handling facilities that can work well with a chute or breeding barn do not have to be expensive. The “Bud Box,” popularized by the late Bud Williams, is just one example of a relatively low-cost handling facility design that can facilitate low-stress handling of livestock (Figures 2 and 3). The alley leading to the Bud Box is generally designed to be 10 to 14 feet wide depending upon cattle temperament and depending upon whether cattle are handled on foot or horseback. Note that the width of the alley does not dictate the width of the Bud Box. Cattle may actually flow more easily into a Bud Box when width of the Bud Box is slightly larger than width of the Alley. The Bud Box should be 12 feet in width if cattle are handled on foot or 16 feet in width if cattle are handled on horseback. A width of 14 feet may be workable if cattle will be handled on foot on some occasions and on horseback on other occasions. Depth of the Bud Box should be a minimum of 20 feet, although deeper Boxes (e.g., 24 feet) may be preferred if the alley to chute or load-out is high-capacity. Bud Boxes designed for loading out large trailer loads of cattle can be designed with even greater depth (e.g., 30 feet). The Alley to Chute or Load-Out should have a capacity that exceeds that of the Bud Box, such that all animals entering the Bud Box flow through in a single draft. A straight alley of at least 24 feet is recommended. A double alley design is preferred by some, especially to increase alley capacity where potential alley length is limited.

Regardless of the facility, personnel handling cattle need to understand how to effectively use the facilities in a low-stress manner, as any facility is only as good as its operators. Figure 3 illustrates low stress handling of cattle in an example Bud Box facility through simple use of body positioning.

For more information on the impacts of handling and stockmanship on cattle stress and reproduction, see MU Extension publication G2047, Managing the Effects of Stress and Temperament on Beef Cattle Reproduction.

Portable breeding barns

A portable breeding barn (Figure 4) can be a good option to AI cattle in a low-stress, efficient manner. University of Missouri Extension has 13 single- or two-stall breeding barns located around the state. These breeding barns can be backed up to a lead up alley. This makes them a good option for farms without squeeze chutes or with chutes that lack palpation cages. In addition, using an enclosed breeding barn can provide protection from harsh weather conditions for locations at which cattle handling facilities are not under-roof.

The barns are floorless and are raised or lowered by a built-in hydraulic pump, allowing cattle to keep their feet on the ground instead of stepping up onto a chute platform. Cattle enter through the sliding back door. The breeding barns keep cattle quiet with little restraint, using a bar that drops behind the cattle to prevent cattle from backing up or kicking the AI technician. Furthermore, each stall is equipped with rubber curtains to block the cow’s view of bright lights or technician movement.

Two-stall breeding barns allow two technicians to be working at the same time, making the AI process of large herds much more efficient. Further, cattle remain calm while standing next to another cow in the two-stall breeding barns. These breeding barns are rented to producers across the state and are easily moved by a half-ton pickup. For more information on renting a breeding barn, contact information for breeding barns across the state is provided in Table 1.

Table 1. Portable breeding barns available through University of Missouri Extension.

| Northwest | North Central | Northeast |

|---|---|---|

| Albany Gentry County Extension One two-stall breeding barn Daily rental fee: $50 To reserve: 660-726-5610 |

Milan - Brookfield Sullivan County Extension One two-stall, one single breeding barn Daily rental fee: $75 for double or $50 for single To reserve: 660-265-4541 |

Novelty Adair County Extension Two two-stall breeding barns Daily rental fee: $75 To reserve: 660-665-9866 Palmyra - Bowling Green Ralls County Extension One two-stall, one single-stall breeding barn Daily rental fee: $75 for double or $40 for single To reserve: 573-985-3911 |

| West Central | Central / West Central | Central / East Central |

| Harrisonville Cass County Extension One two-stall breeding barn Daily rental fee: $75 To reserve: 816-380-8460 |

Sedalia Pettis County Extension One two-stall breeding barn Daily rental fee: $75 To reserve: 660-827-0591 |

|

| Southwest | South Central | Southeast |

| Mount Vernon Lawrence County Extension One two-stall breeding barn Daily rental fee: $75 To reserve: 417-466-3102 |

Salem Dent County Extension One two-stall breeding barn Daily rental fee: $50 To reserve: 573-729-3196 |

Jackson Cape Girardeau County Extension One two-stall breeding barn Daily rental fee: $50 To reserve: 573-243-3581 |