Editor’s note

See Drone Spray Cost Estimator: Custom Operation Version (XLSX) and Drone Spray Cost Estimate: Farmer Version (XLSX) for related information.

The rapid development of drone technology offers significant potential for precision agriculture, allowing farmers to monitor crops and livestock; apply seed, fertilizers and pesticides; and assess land conditions with increased accuracy and efficiency. Though drones can provide substantial benefits in farm management, the question of whether owning drones is cost-effective compared to traditional methods — such as hiring airplanes, machinery or human labor — remains crucial for many farmers. This analysis estimates the costs of owning and operating an Agras T40 drone for spraying applications (Figure 1). This model can carry up to 10.6 gallons of spray and 110 pounds of spread load, a total of 18.5 gallons, allowing for spraying, spreading, surveying and mapping.

This guide focuses on determining whether the investment in drone technology offers a competitive edge in terms of cost and operational efficiency, and it introduces two tools developed to estimate the cost per acre of using drones for agricultural spray applications by farmers and custom operations. These tools identify the key cost components and analyze how they vary with drone usage (based on the number of acres treated annually) and interest rates.

Initial investment cost

Costs per acre for an application include ownership and operating costs. Ownership costs occur regardless of machine use and include depreciation, interest, taxes, insurance, and housing for the drone and additional equipment required. Operating costs vary directly with the use intensity, or acres applied per year, and include repair and maintenance, fuel, lubrication and labor costs.

To estimate all these cost components, assumptions must be made. Investment costs for the drone enterprise include the drone, batteries, a charger, a generator, and equipment to transport the mix to the field and load it into the drone. The ownership costs per acre include the costs of buying and owning these items, which include interest and depreciation. To estimate that, we assume the equipment prices, lifespan, maintenance and salvage value presented in Table 1.

Table 1. Equipment required for drone use for farmers and custom operations.

| Equipment | Price of new unit (dollars) | Lifespan | Salvage value (dollars) | Annual maintenance costs (dollars) | Percentage use for drone application |

|---|---|---|---|---|---|

|

Drone package (includes a charger) |

23,000 |

8,000 acres |

6,900 |

Farmer’s: 1,000.001 Custom: 4,000.001 |

100 |

|

Generator |

7,500 |

10 years |

2,625 |

253.13 |

100 |

|

Trailer (farmer’s operation) |

9,000 |

10 years |

3,150 |

303.75 |

50 |

|

Trailer (custom operator) |

14,500 |

10 years |

5,075 |

489.38 |

100 |

|

Truck |

50,000 |

10 years |

15,000 |

406.25 |

25 |

|

Tank, pump and transfer system (farmer’s operation) |

1,000 |

10 years |

300 |

97.50 |

100 |

|

Tank, pump and transfer system (custom operator) |

1,500 |

10 years |

450 |

146.25 |

100 |

|

Batteries (for drone, each) |

2,500 |

5 years2 |

500 |

100 |

|

|

Total for a farm3 |

56,000 |

||||

|

Total for a custom operation3 |

94,500 |

||||

|

|||||

Table 2 describes the additional assumptions adopted for the estimates of cost per acre presented in this guide.

Table 2. Additional assumptions of this analysis.

| Item | Value for farmers' tool | Value for the custom operators' tool |

|---|---|---|

| Acres applied per charge cycle | 6.5 | 6.5 |

| Acres applied per flight | 6.5 | 6.5 |

| Acres of drone lifespan | 8,000 | 8,000 |

| Applied acres per year | 1,000 | 4,000 |

| Charges of battery lifespan | 1,000 | 1,000 |

| Daily miles driven | 20 | 60 |

| Diesel price (dollars per gallon) | 3.31 | 3.31 |

| Diesel use (gallons per hour) | 1.10 | 1.10 |

| Dish soap price (dollars per 2.64 liter) | 25.30 | 25.30 |

| Dish soap quantity (liters per day) | 0.10 | 0.10 |

| Drone cleaning (hours per day) | 0.50 | 1.00 |

| Drone crew members | 1 | 2 |

| Hours per day applying | 6 | 6.5 |

| Hours per day driving to and from fields | 1 | 2 |

| Interest rate (percent) | 8 | 8 |

| Labor cost (dollars per hour) | 21 | 30 |

| Loads per day | 24 | 52 |

| Number of batteries | 3 | 5 |

| Number of drones | 1 | 2 |

| Nonoperating field hours | 0.83 | 1.72 |

| Pickup fuel economy (miles per gallon) | 12.50 | 12.50 |

| Pumping in and mixing (hours per load) | 0.08 | 0.08 |

| Time recharging battery (hours per load) | 0.17 | 0.17 |

Cost of owning drones for spray applications

The estimated costs per acre for the hypothetical farming and custom operations are presented in Table 3. The results show that the total cost per acre for drone applications, based on the assumptions in Tables 1 and 2, is $12.27 per acre for farmers and $7.39 per acre for custom operators. For comparison, custom hire rates for drone spray applications are typically around $16 per acre, and fungicide applications using crop dusters are about $12.50 per acre. These estimates suggest that, under the outlined assumptions, owning a drone may be a cost-effective option for a farm operation using drone application for at least 980 acres, and there is a competitive margin for custom operators interested in providing drone spraying services.

Table 3. Estimated costs of using the T-40 drone for agricultural spray applications.

| Component | Cost per acre applied (dollars per acre) |

Cost per year for the operation (dollars) |

||

|---|---|---|---|---|

| Costs | Farmer | Custom operator | Farmer (1,000 acres per year) | Custom operator (4,000 acres per year) |

| Fuel | 0.15 | 0.15 | 145.26 | 589.08 |

| Labor | 1.05 | 1.06 | 1,054.49 | 4,240.63 |

| Other materials | 0.02 | 0.01 | 16.22 | 29.94 |

| Maintenance/Repairs | 2.06 | 1.32 | 2,060.63 | 5,295.00 |

| Interest over operating capital | 0.10 | 0.10 | 97.28 | 388.77 |

| Total operating costs (dollars per acre) | 3.37 | 2.64 | 3,373.87 | 10,543.42 |

| Depreciation + interest over capital (excluding batteries) | 6.58 | 3.84 | 6,584.40 | 15,369.46 |

| Batteries | 1.72 | 0.72 | 1,720.93 | 2,868.22 |

| Taxes + insurance + housing | 0.59 | 0.20 | 592.38 | 782.25 |

| Total ownership costs (dollars per acre) | 8.90 | 4.75 | 8,897.70 | 19,019.93 |

| Total costs (dollars per acre) | 12.27 | 7.39 | 12,271.57 | 29,563.35 |

Another key finding from Table 3 is that ownership costs represent the largest component of total costs per acre. This indicates that the number of acres sprayed annually and the interest rate on capital significantly influence the economic feasibility of using drones in farming operations.

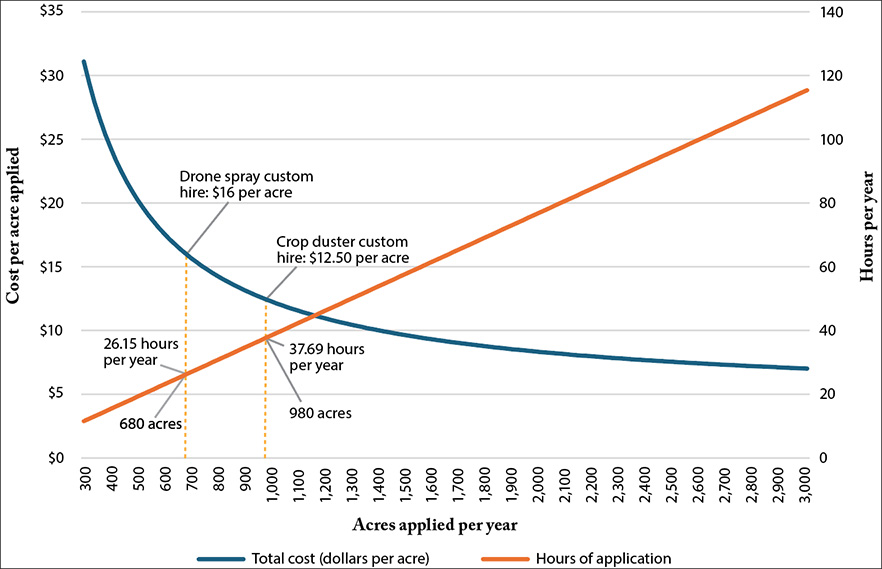

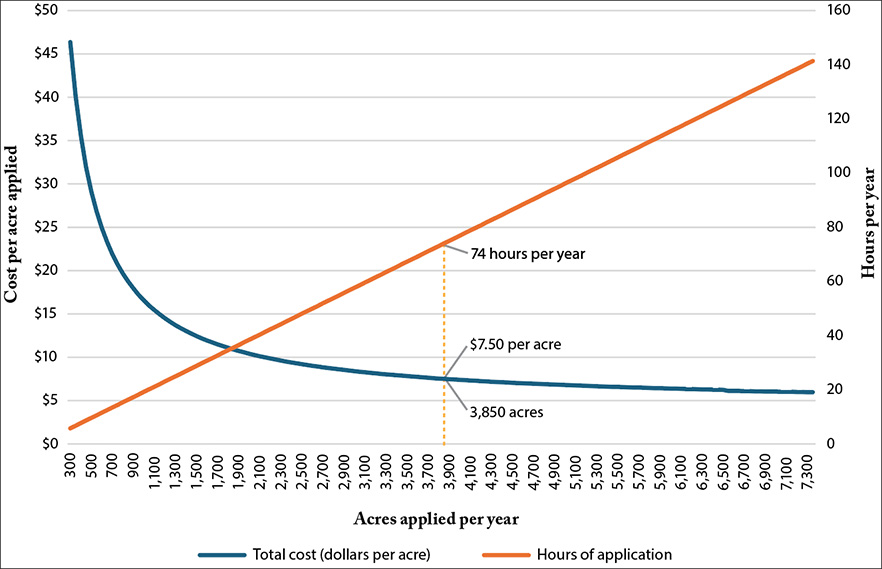

An analysis of the acreage applied per year (Figure 2) reveals that, under our assumptions, the cost of drone applications will drop below $12.50 per acre for farm operations applying 980 acres or more annually. For custom operators, the cost will drop below a target cost of $7.50 per acre if at least 3,900 acres are applied annually (Figure 3).

The high ownership costs associated with drone use for spray applications can be spread with greater use intensity, which decreases total costs per acre. However, the potential to reduce application costs by increasing acreage may be constrained by the time required to complete the spraying. For instance, a drone application for farmers spraying 980 acres per year would require 37.69 flight hours to be completed at a cost of $12.43 per acre. For farmers covering 2,000 acres annually, the cost could drop to $8.32 per acre but would require 76.92 hours of flight time. These time constraints could pose a challenge for operations with only one drone and a limited application window.

The relationship between the number of acres applied per year and the number of batteries also significantly impacts the cost of drone applications. In this guide, it is assumed that farmers purchase three batteries, two for use and one for backup, and one drone, and that custom operators purchase five batteries, four for use and one for backup, and two drones.

Each battery has a lifespan of 1,000 charge cycles, but its ability to store energy begins to degrade after five years. A battery can be fully charged in 10 minutes, which provides sufficient time to recharge between flights and while refilling the drone with the spray mix. Considering these factors, the most cost-effective strategy is to limit the purchase of extra batteries so that each battery can reach its full charge cycle potential before degradation.

Additionally, the interest rate on capital significantly affects application costs. For an operation using their drone over 1,000 acres, reducing the interest rate from 8% to 6.5% lowers the cost of drone applications from $12.27 to $11.55 per acre.

Download the tools

- Drone Spray Cost Estimator: Custom Operation Version (XLSX)

- Drone Spray Cost Estimate: Farmer Version (XLSX)

This publication was supported by the NRCS-USDA Missouri Conservation Innovation Grant (CIG) no. NR236424XXXXG013.

The University of Missouri intends neither endorsement of products named in this guide nor criticism of similar products that are not mentioned.