schedule

Dates

location_on

Delivery method

Blended

credit_card

Cost

$1800.00

Registration Closed

Description

Syllabus

Course Overview:

This hybrid course provides an in-depth exploration of state-of-the-art smart manufacturing systems, which leverage advanced technologies and data-driven approaches to optimize and automate various aspects of manufacturing processes. The course will teach students to design, implement, and manage various smart manufacturing systems. Participants will gain a comprehensive understanding of the key components, technologies, and methodologies involved in smart manufacturing with various hands-on projects, pushing them forward into areas of smart manufacturing and Industry 4.0.

Format:

This hybrid course is delivered over a six-week period. The first two weeks are online only, with the participant acquiring fundamental knowledge that will be utilized throughout the course. Each online learning module is supplemented with an online quiz that the participant must pass. Allow approximately three to four hours each week to complete the online work. Online work is completed each week at the day and time that works with the learner’s schedule.

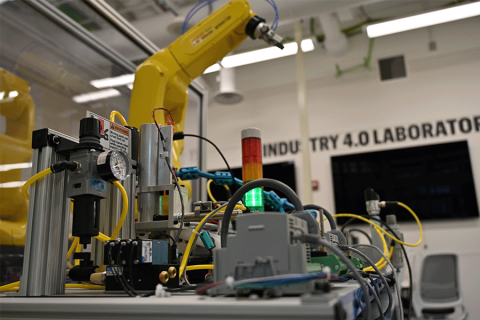

The final four weeks are composed of both online learning blocks and hands-on learning labs in the Industry 4.0 Suite at Mizzou Engineering. Each applied lab is scheduled for 8-hours. During the lab sessions, participants will engage in project-based learning using state-of-the-art equipment and software.

The online coursework starts July 7, 2025 and ends August 12, 2025.

In-person lab days are July 23rd and 30th and August 6th and 13th.

Prerequisite:

Must complete Industry 4.0 Industrial Automation topic certificate and/or have PLC experience to enroll.

Learning Outcomes:

Upon successfully completing this course, participants will be able to:

- Understand the fundamental concepts and principles of smart manufacturing systems and Industry 4.0.

- Develop the skills to design and integrate smart manufacturing solutions.

- Apply various cutting-edge technologies and components in smart manufacturing.

- Integrate robotic systems with sensors, actuators, and control systems to enhance production efficiency.

- Identify the role of data analytics and artificial intelligence in optimizing smart manufacturing processes.

Course Topics and Schedule:

- Week 1: Lecture 1- Introduction of Smart Manufacturing and Overview

- Week 2: Lecture 2- Digital Twin–Based Smart Manufacturing

- Week 3: Lecture 3- Sensors and Data Acquisition / Lab 1- Internet of Things (IoT) and applications (Raspberry Pi with MQTT)

- Week 4: Lecture 4- Data Analytics and Artificial Intelligence (AI) in Manufacturing / Lab 2- Introduction to data visualization tools

- Week 5: Lecture 5- Cyber-Physical Systems / Lab 3- Introduction to software (Factory I/O)

- Week 6: Lecture 6- Industrial Automation and Robotics / Lab 4- Autonomous robot (MiR250) with Cobot (Universal Robots)

Instructor:

Yi Wang, Ph.D.

Department of Industrial and Systems Engineering

Mizzou College of Engineering

Department of Industrial and Systems Engineering

Mizzou College of Engineering

Length:

6-weeks

Department:

Mizzou College of Engineering

Credit:

Non-credit | Adult Learner

Audience:

Individuals working in manufacturing setting

Accommodations

University of Missouri Extension complies with the Americans with Disabilities Act of 1990. If you have a disability and need accommodations in connection with participation in an educational program or you need materials in an alternate format, please notify your instructor as soon as possible so that necessary arrangements can be made.

Cancellations and Refund Requests

Access MU Extension’s Course Cancellation and Refund Policy for details.