Editor’s note

This publication is also available in Spanish. (Esta publicación también está disponible en español.)

Up to 15% of delivered feed is estimated to be wasted annually. A primary culprit? Likely, improper feed pan coverage and mismanaged feeders. It is well known that producers who focus on managing this critical factor can considerably enhance feed efficiency and improve profitability. Although the concept “Every Feeder, Every Pen, Every Day” is not new, achieving success requires caretakers to adopt the practice fully. Securing their commitment begins with offering clear and compelling reasons for its value. To assist in this effort, we have created a bilingual (Spanish) simplified resource on pan coverage: GS2325, Cobertura en el Comedero: Controlando los Controlables para Mejorar la Utilización del Alimento.

Why managing feeders matters

Feed is the single greatest input cost of pork production. Feed efficiency, the ability to convert feed into body weight gain, is impacted by how pigs interact with and access feed from the feeder. Pan coverage, which indicates the percentage of the feeder's flat surface covered by feed, can impact feed efficiency. Wasting feed can add up to the overall cost of production and could represent an extra cost of between 2 and $10 per pig (Table 1).

Table 1. Estimated impact of feed wastage on feed cost per pig

| % Wasted | $ Feed/pig | $ Diff/pig |

|---|---|---|

| 0 | 68.00 | -- |

| 2 | 69.36 | 1.36 |

| 4 | 70.72 | 2.72 |

| 8 | 73.44 | 5.44 |

| 10 | 74.80 | 6.80 |

| 15 | 78.20 | 10.20 |

| 20 | 81.60 | 13.60 |

| Feed cost estimate based on corn-soy diet on 2/4/25. | ||

Good production practices are critical in increasing feed intake and reducing wastage. Many of these strategies are out of the hands of caretakers, such as feeder design, feed type (pellet or mashed), particle size, and nutrient density in the diet. However, one of the most influential practices that employees can control is feeder management to optimize pan coverage. The major reasons for managing pan coverage are to reduce the likelihood of feed ending up in the pit and prevent out-of-feed events. Another practical reason for optimal pan coverage is that it can aid in preventing feed gates from getting clogged.

Achieving optimal pan coverage

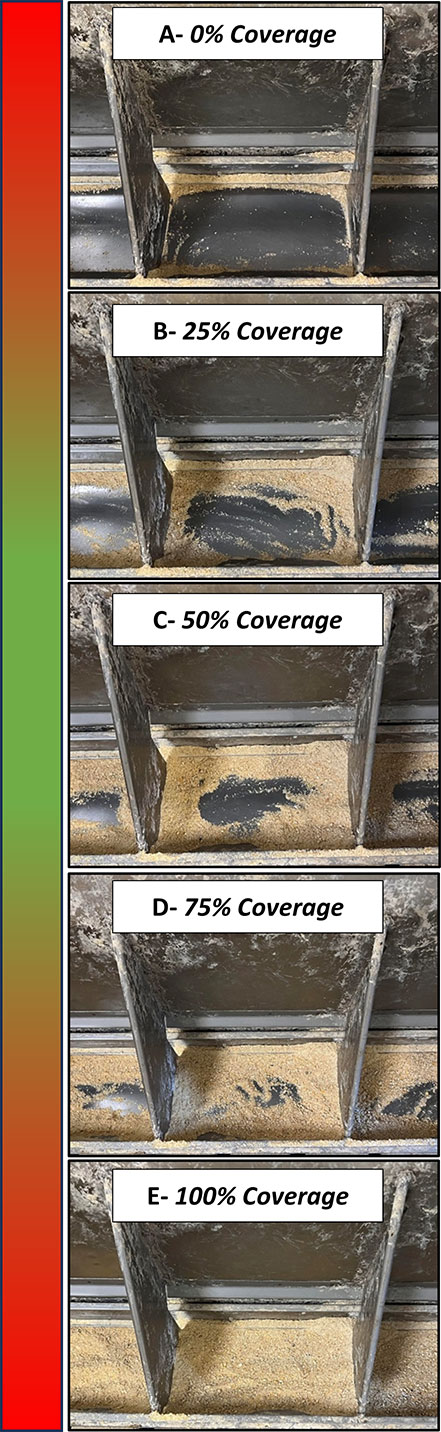

Every feeder in every pen should be adjusted every single day to maximize feed utilization. Being consistent in managing and cleaning feed gates can improve your closeouts. How much pan coverage for a pen will depend on several factors, including phase of production, stocking density, and type of feed, among others. The scale in Figure 1 can help to visualize and appraise optimal pan coverage to target each day.

Nursery pan coverage

At nursery fill, pan coverage should be targeted around 50-70% (between images C-D), and 3 to 7 days post-placement, it should be reduced to 35–50% (between images B-C) depending on feeder design1. Encouraging feeding behavior in young pigs requires a higher feed flow during early post-weaning but needs to be gradually reduced to minimize waste2. However, after the first week, feed coverage greater than 50% will lead to reduced feed efficiency and greater cost for the producer3.

Grow-finish pan coverage

For most of the grow-out period, feed pan coverage should be between 35-50% (Image C), and after 1st cut, reducing it to between 30-40% can further improve feed efficiency. This will improve feed efficiency and sustainability by limiting feed in the pit. On the other hand, a feed gate that is too tight and limits feed coverage to less than 10% (Image A) can reduce feed intake and gain by up to 30% while also increasing pen aggression2. So, be careful not to limit feed access either.

In conclusion, even well-designed feeders can waste feed if not properly adjusted. It’s essential to inspect feeders and remind staff to do so daily. Taking the time to adjust feeders can significantly impact feed efficiency, optimizing production outcomes and profitability. Although it may seem tedious, prioritizing feeder management every day will have a direct effect on feed utilization.

This article is also available in Spanish: GS2325, Cobertura en el Comedero: Controlando los Controlables para Mejorar la Utilización del Alimento.

References

1Pig Improvement Company, PIC. “Wean to Finish Guidelines,” 2019. January 1.

2Miller, KA., Johnson, EM., Matchan, SA., Goehring, D., Ross, JW., Gabler, NK. Strategies to manage barn feed supply to prolong and hold late finishing pigs during a supply chain disruption, Translational Animal Science, Volume 7, Issue 1, 2023, txac166.

3Myers, AJ., Goodband, RD., Tokach, MD., Dritz, SS, DeRouchey, JM., Nelssen, JL. The effects of feeder adjustment on growth performance of finishing pigs. J. Anim. Sci. 2012.90:4576–458.

4Zeamer KM., Levesque, CL., Cortus, EL., Thaler, RC. Findings from a survey of finishing-barn management benchmarks with South Dakota pork producers. Applied Animal Science 37:320–333.