Peter Scharf, Plant Sciences Extension

Peter Scharf, Plant Sciences Extension

In collaboration with

Missouri crop producers use a wide range of practices to supply nitrogen to their crops. The timing, rate and method of application, as well as the source of nitrogen and the use of additives, vary widely across the state and often between neighbors. Under certain weather conditions, nitrogen can be lost from the soil between application and crop uptake. This publication is intended to describe crop production practices that have the greatest potential for success in dealing with the complexities of managing nitrogen fertilizer.

Successful nitrogen management delivers enough nitrogen to the crop to optimize yield and profitability while minimizing losses to water and air. With nitrogen, economic success and environmental success overlap almost completely. Everyone wants the nitrogen to end up in the crop. Thus, the best management practices (BMPs) presented here are identified as sound practices from economic, production and environmental viewpoints.

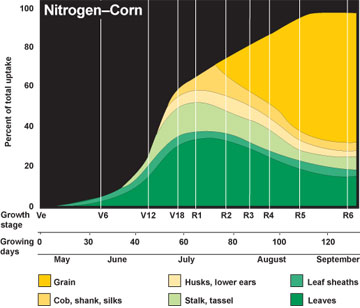

Figure 1

Figure 1

Maximum nitrogen uptake occurs in periods of maximum growth (in corn roughly between vegetative growth stages V9 and V18, or from hip-high to just before tasseling). Risk of N loss is low during this period. Credit: Iowa State University Extension.

Nitrogen fertilizer timing

The BMP for timing of nitrogen (N) fertilizer applications is to apply fertilizer as close as possible to the period of rapid crop uptake (Figure 1). Managing N in this way will minimize losses of N from the field and will ensure adequate N availability to the crop during critical growth periods. These benefits, however, must be balanced against the risks associated with a smaller time window for N application, and against other time-sensitive field operations that may be necessary at the same time that N applications would be most efficient.

Timing and risk of N loss

Nitrogen fertilizer can be lost from agricultural fields especially in regions with moderate to high rainfall. In most years, some region of Missouri gets enough rainfall to cause N loss.

The period with the greatest risk of N loss is spring, when soils tend to be wet and before rapid crop growth begins to pump water out of the soil. This risk ends sooner with crops that begin rapid growth early in the spring, such as wheat and grass. Early spring application of N for summer crops like corn and milo can result in loss of N and reduction in yield. If N is to be applied more than two weeks before planting, use of anhydrous ammonia is recommended to reduce this risk.

A second period of high risk for N loss can occur in late May and June for corn, milo and cotton. Even though rapid crop growth may have started, if heavy rains create saturated or near-saturated soil conditions for several days or longer, the combination of warm and wet soil conditions can lead to rapid N loss through denitrification. This risk is greatest on poorly drained soils. Sidedress application of N or use of a nitrogen stabilizer such as N-Serve with preplant applications will reduce this risk.

In all crops, rapid uptake of N occurs during the maximum growth period. There is not much risk of N loss when fertilizer is applied at the beginning of the period of rapid growth.

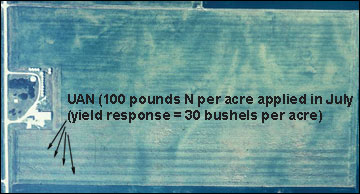

Figure 2

Figure 2

Nitrogen application to growing crops (sidedressing or topdressing) is an efficient delivery method. This technique is common in wheat, rice, cotton and forage grasses but less so in corn because delays due to weather can necessitate use of high-clearance equipment.

Applying N close to the period of maximum crop growth

Row crop producers in Missouri have, in many cases, substantially changed the timing of their N applications over the past 40 years to apply N closer to the period of maximum crop growth. These changes recognize the risk of yield loss that comes with early applications.

For example, wheat and other small grains used to be fertilized mainly before planting in the fall. Spring topdress applications of N are now almost universal, because losses of fall-applied N were too common to be affordable (Figure 2). Early (January or February) topdress applications can sometimes be lost before the main uptake period in April and May. Risk is especially high if N is applied to frozen soils.

Another example is sidedressing of N fertilizer for corn in the Mississippi Delta region (bootheel). It is now normal in this region for the largest N application to be made at an early sidedress timing. This region receives more rain than anywhere else in Missouri, creating a relatively high risk of losing N that is applied before corn planting. Another factor favoring adoption of corn sidedressing in the bootheel is that the sandy soils common there are among the highest-risk soils for loss of fertilizer N. Sidedressing corn is not common in other parts of Missouri, but there are signs that this practice may be increasing.

Missouri rice and cotton producers have also adopted in-season applications. Rice producers typically make a preplant application of N fertilizer followed by one or two aerial applications near the maximum growth period. These applications ensure that enough N is available to support the rapid growth that the crop needs to achieve its full potential.

Cotton producers often apply more than half of their N fertilizer during the squaring or prebloom stages of crop growth. This not only reduces risk that N will be lost but also helps to promote boll growth as opposed to vegetative growth, thus increasing profit.

In corn, the goal of applying the fertilizer close to the period of rapid crop uptake means that sidedress applications are preferable to preplant applications, and preplant applications are preferable to fall applications. Fall N applications, in particular, are currently considered a high-risk practice in Missouri. In some years, fall N applications will produce optimal yields, but in years with unfavorable weather conditions, yield losses can be large even when the best practices for fall N applications are followed. These practices are described in the following section on fall N applications.

Pivot irrigation systems provide another tool for making nitrogen applications to corn during the period of rapid N uptake. Nitrogen can be injected into irrigation water and applied uniformly over the field. Yield response to N "fertigation" has been seen only when the corn color indicates N stress. Stress can be evaluated using hand-held meters, aerial photos, or vehicle- or pivot-mounted sensors. The economic potential of this system is greatest if early N applications are modest and fertigation is used to "top up" the crop.

Perennial grasses for hay, pasture or turf are an exception to the rule that nitrogen is best applied just before the period of maximum growth. For hay and pasture, risk of N loss during wet weather is minimal. In many cases it may be desirable to fertilize pasture not when the grass is growing fastest, but when the extra forage will be most useful. Application in May to extend summer grazing or in August to produce stockpile for winter feeding can be good strategies. For details, see the chapter "Soil Fertility Management and Nutrient Cycling" in the M157, Missouri Grazing Manual. For turf, slow and even growth is most desirable, and multiple, small applications of N fertilizer or use of slow-release forms of N is relatively common.

Fall application of N fertilizer

Although fall application of N fertilizer for a corn or milo crop grown the next summer is considered to be relatively high-risk and not a BMP in Missouri, producers nonetheless sometimes are willing to take this risk in order to apply the nitrogen at a lower cost and without interfering with their spring fieldwork. When applying N in fall, the following practices are recommended to minimize risk:

- Only anhydrous ammonia should be used for fall N applications. All N fertilizers convert to nitrate in the soil, and nitrate is the form of N that can be lost. Ammonia converts to nitrate slower than any of the other forms of N, and risk of loss is much lower than for any other form.

- Use of N-Serve with anhydrous ammonia is a BMP and may be especially important when N is applied in the fall. N-Serve slows the conversion of ammonia to nitrate and reduces the risk of loss. This BMP is discussed further in the section below on additives.

- No more than half (preferably no more than a quarter) of planned corn and milo acres should receive N in the fall. This practice limits the number of acres at risk, and balances the convenience of fall N application with the economic and environmental risks.

- No anhydrous ammonia should be applied before the soil temperature at a 6-inch depth reaches 50 degrees. The 50-degree rule was developed in states where soil cooling after 50 degrees is much faster than in Missouri. Waiting until soil temperature reaches 40 degrees is recommended for Missouri. Once soil temperature drops below this level, ammonia conversion is slow and risk is reduced but not eliminated.

- The risk of losses from fall N applications increases in Missouri the farther south you go. The University of Illinois recommends that no fall N applications be made south of Highway 16 in Illinois, which roughly corresponds to Highway 36 in Missouri running from St. Joseph to Hannibal. MU does not use a "line" approach, but the consensus is that more caution is warranted as you go south.

- Iowa research in fields with high-pH spots indicates that these spots are the areas where loss of fall-applied N is most likely to occur. Conversion of ammonia to nitrate is faster at high pH. The only fields in Missouri with high native soil pH are found in the Missouri River bottoms. Fall N applications are not recommended on these fields or on any fields that have been limed to a water pH of 7.2 or higher (salt pH of 6.7 or higher).

Figure 3

Figure 3

Risk of N loss is higher with fall applications than with spring applications. In this cornfield, light green areas are the result of loss of fall-applied N.

Additional N fertilizer applied in July (strips at bottom of photo) corrected the N deficiency, made the corn darker green, and improved yield. Most fields receiving fall N applications do not lose as much N as in the field shown.

A. Blackmer photo

Use of caution and practices to minimize and manage risk are crucial if fall N applications are made in Missouri (Figure 3).

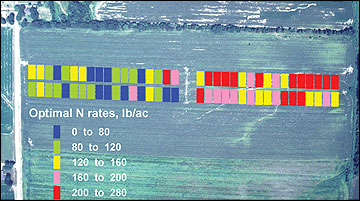

Figure 4

Figure 4

This cornfield near Centralia, Mo., needed much more N to reach full yield potential in the eastern (right) half of the field than in the western half. Most fields that have been studied in Missouri have different N need in different parts of the field.

Fertilizer application rate

Best management practices for nitrogen fertilizer application rate are poorly developed, but some promising new practices are on the horizon. Nitrogen fertilizer rate is one of the most important N management variables, both economically and environmentally.

The amount of N fertilizer needed to optimize crop yield often differs significantly from one field to another, and from one part of a field to another part (Figure 4). Unfortunately, the tools available to predict how much N is needed are not yet very satisfactory for most crops under Missouri conditions. Yield goal is the main tool for predicting N fertilizer rate in most crops, but yield level seems to play only a small role in determining how much N fertilizer is needed. Variation in the ability of the soil to supply N to the crop is the main factor that determines how much N fertilizer is needed to optimize yields.

Nitrogen application rates based on yield goal supply enough N to maximize crop yield in almost all situations. If N application timing does not expose N to loss, there is not much potential to improve crop yields by increasing N rates, but there is potential in many fields to save on the nitrogen fertilizer bill without losing yield. This is increasingly important to profitability as N prices go up.

Fertilize for normal yields. Even in years with excellent yield potential, increasing N rates above rates associated with normal yields is rarely needed. Conditions that are good for corn growth are also good for microbial activity that releases N from soil, and the soil tends to supply more N to the crop in these years.

U.S. crop producers have made good progress with efficient use of N fertilizer. Over the past 25 years, total use of N fertilizer has remained nearly constant, while crop yields have increased substantially. Using corn as an example, U.S. producers now apply about one pound of nitrogen per bushel of corn produced, which is down from the peak of 1.3 pounds per bushel in the late 1970s.

Crop color appears to be the most reliable indicator of how much N is needed for a range of crops. Lighter color indicates more N stress and a need for higher N rates. This approach only works for fertilizer applications made during the growing season. Most producers make in-season applications of N to wheat, rice, cotton, and forage grasses, but not to corn, which receives about half of the N fertilizer applied in Missouri. Although corn color is the best predictor of how much N fertilizer is needed, it does not fit with the preplant N management system favored by most Missouri corn producers. As nitrogen prices and environmental pressures increase, the usefulness of color-based N sidedressing for corn may increase. Sensors can be mounted either on tractor-based or high-clearance sidedressing equipment and can control application rates of sidedress N. This approach is also being tested in wheat and cotton and may turn out to be useful for milo and grass as well.

Soil nitrate samples taken in spring can be useful for adjusting N fertilizer rate when there is a reason to suspect fairly high N availability from the soil, such as in fields that have been manured, or following a drought year (especially when corn follows corn). Research in Missouri shows that most fields have fairly low levels of soil nitrate, even when the ability of the soil to supply N to the crop is fairly high. Experience also shows that it is safer to interpret soil nitrate test results using a credit system than index systems from other states.

Soil N credits can also be useful tools. Credits for manure N based on manure analysis or on book values are fairly reliable, and research shows that it is profitable to use manure N credits. A credit of 100 pounds N per acre for a previous alfalfa crop or 50 pounds N per acre for a previous clover crop (more than one year) is fairly reliable and safe as long as the stand still had 30 to 40 percent legume ground cover at the time of termination. Nitrogen credits for a previous soybean crop are somewhat controversial at this point, but use of a credit of 30 pounds N per acre carries minimal risk.

Nitrogen components of phosphorus (P) fertilizers can also be safely credited if they are spring-applied. Crediting half the N is safer if the P was applied in the fall before growth of a summer crop. Nitrogen components of starter fertilizers and nitrogen applied with herbicides should be included as part of the total intended N rate.

Varying N rate based on soil type, soil drainage class, soil texture, soil electrical conductivity or soil productivity index has not yet been shown to work well in the Missouri crops where these approaches have been tested. There are indications that the need for nitrogen increases on poorly drained soils and on clay soils (with high electrical conductivity).

The cornstalk nitrate test developed by Iowa State University (Iowa State Extension publication PM-1584, Cornstalk Testing to Evaluate Nitrogen Management) is a reliable way to diagnose N rate at or near harvest and has been tested well in Missouri. It cannot be used to guide N application rate, but can be used to tell whether the N rate in a particular area was too low, optimal or excessive. Feedback gained from this test can help producers improve rate decisions in following years.

Nitrogen fertilizer sources

Ammonium nitrate, anhydrous ammonia, urea and urea-ammonium nitrate (UAN) solution are the four main N fertilizer sources used in Missouri. All are excellent fertilizer materials. Most BMPs in choosing a nitrogen fertilizer source relate to timing, fertilizer application methods or placement, and use of additives and are described in more detail in corresponding sections of this publication. Other BMPs relating to fertilizer source are as follows:

- No special management practices are needed for ammonium nitrate; surface broadcast applications are effective. Avoid early applications of ammonium nitrate as well as urea and UAN solution. Quality is important in achieving even spreading of dry N sources, especially ammonium nitrate.

- Urea should not be broadcast and left on the surface for extended periods. Missouri research has shown a 14 bushels per acre yield penalty in corn (average of 38 experiments, mostly no-till) and a 5 bushels per acre yield penalty in wheat (average of 9 experiments) when urea is broadcast and not incorporated. The following options are acceptable management choices for urea:

- Treatment with Agrotain volatilization inhibitor before broadcasting.

- Incorporation into soil with tillage (within 3 or 4 days of application).

- Incorporation with irrigation (within 3 or 4 days).

- Knife injection.

- UAN (urea-ammonium nitrate) solution (28 percent to 32 percent N) should not be broadcast on high-residue surfaces. Missouri research has shown a 25 bushels per acre yield penalty when solution is broadcast in no-till corn (average of 20 experiments, mostly corn-soybean rotation). In other conservation tillage systems with less residue, less yield loss would be expected. Dribbling solution reduces contact between nitrogen and residue, and injection is best. Practices described above for urea can also be worthwhile.

- Only anhydrous ammonia should be used for fall applications of N. See other recommended practices in the fertilizer timing section.

- Anhydrous ammonia applied in spring is the N source with lowest risk of loss and is the BMP for fields with higher risk of loss (sandy or poorly drained fields).

- Anhydrous ammonia applications may benefit from addition of N-Serve, especially in the fall but also in the spring (particularly if soils are poorly drained or sandy).

- Anhydrous ammonia should not be applied when soils are wet because the ammonia gas may leak out of the slot, which will be difficult to close.

- Extensive use of ammonium sulfate as an N source will lead to twice as much soil acidification as any other N source. Monitoring soil pH becomes more important when ammonium sulfate is used.

Application methods and placement

Nitrogen fertilizer materials lend themselves to a range of application methods, including broadcast application, surface banding, knife or coulter injection and application with the planter. Choice of method and placement is related to the source of N. (See previous section.)

Broadcast applications can be used with urea, ammonium nitrate and UAN solution. However, broadcast applications of urea can result in substantial loss of fertilizer N to the air. Treatment of urea with Agrotain before broadcasting, or incorporating the urea into the soil with tillage or irrigation within three or four days, will reduce or prevent N loss.

Broadcasting UAN solution (28 percent to 32 percent N) is not recommended when residue levels are high because of the potential for the N in the droplets to become tied up on the residue. Dribbling the solution in a surface band will reduce tie-up on residue, and knife or coulter injection will eliminate it. Limited research suggests that the same conclusions probably apply for grass hay or pasture.

Broadcast UAN solution is also susceptible to volatile loss of N to the air in the same way as urea, but only half as much will be lost (half of the N in UAN solution is in the urea form). The same treatments that reduce volatile loss from urea work with UAN solution (Agrotain, tillage, irrigation or injection) but are not as necessary.

Figure 5

Figure 5

Broadcast applications are suitable for ammonium nitrate, for urea that has been treated with Agrotain or that will be tilled in, and for N solution applied in low-residue fields. Boom spreaders often give more even application than spinner spreaders.

No special management considerations are needed for broadcast applications of ammonium nitrate (Figure 5).

Surface banding of N can be useful mainly when UAN solution is the N source of choice on a field with substantial residue cover, and the producer does not want to inject the solution.

Injection is required for anhydrous ammonia to keep the fertilizer N in the field, because ammonia becomes a gas once it leaves the pressurized tank. Injection while soils are wet frequently causes poor closure of the slot behind the applicator, allowing ammonia to escape from the slot. Application to dry, sandy soils can also result in ammonia escaping into the air. Ammonia injection works best at moderate soil moisture but can also work well in dry soils that are medium- to heavy-textured.

Injection can also be an excellent management option for urea or UAN solution, because it prevents volatile losses of urea and also prevents tying up the UAN solution on residue.

Application of N with the planter (starter fertilizer) sometimes increases corn yield in Missouri. When starter fertilizer increased yield in Missouri trials, it was almost completely due to the N component of the starter. Starter fertilizer applied 2 inches below and 2 inches to the side of the seed furrow generally gives larger yield responses than starter fertilizer applied in the furrow.

Figure 6

Figure 6

Most fields in Missouri with visible N loss (light green or yellow areas) also show some streaking of the yellow. Streaks indicate uneven N availability, which may be related to uneven applications of N fertilizer or uneven residue distribution by combines.

Evenness of fertilizer applications

Evidence of uneven N fertilizer applications can be seen in wet years when excessive rainfall causes loss of nitrate-N from soil. The lighter colored areas seen in Figure 6 are areas of N deficiency and are associated with substantial yield reductions. In many Missouri fields with N deficiencies, the presence of streaks suggests an uneven availability of nitrogen due to management practices. Uneven application of N fertilizer is probably the main reason for these streaks, although other factors such as uneven residue distribution behind a combine may also cause streaks. Areas that received higher residue would tie up more N, decreasing its availability.

These streaks are visible only in years with N loss, when they probably cause substantial loss of yield. However, the streaks probably exist every year in fields that are managed similarly. Whether they affect yields in years without major N loss is not known.

The potential for uneven application of N fertilizer is related to the method of application. The methods can be ranked from greatest to lowest potential for uneven application as follows:

- Spinner spreaders to broadcast ammonium nitrate or urea (highest potential for uneven application)

- Anhydrous ammonia

- Boom-type spreaders to broadcast ammonium nitrate or urea

- Broadcast or injected UAN solution (lowest potential for uneven application).

Spinner spreaders can give even applications, but they need to be checked, adjusted and maintained regularly. Wear on parts, the effects of humidity on material flow, and the problems due to variable particle size are probably important sources of uneven application. Poor-quality fertilizer materials contain a high proportion of fines and are difficult to spread evenly. Double spreading may help to achieve even applications when material quality is poor. Driving at an inappropriate overlap distance has also been a considerable source of error. The distance may be wrong for the granule size (bigger granules throw farther) or may be different from the intended distance. Guidance technologies are increasingly used to prevent this type of error.

Many anhydrous ammonia applicators give uneven applications, particularly applicators with older manifolds. Manifold outlets across from the intake usually put out higher rates than outlets near the intake. These manifolds tend to distribute the ammonia unevenly to the knives. Even when the intake is on top, the outlets opposite the direction from which the ammonia approaches the manifold tend to show higher output rates. This uneven output causes the greatest problems when hoses are lined up in order. Often the outside knives are connected to the outlets closest to the intake and get the lowest rates. If the two outside rows are getting lower rates, then when the operator turns around at the end of the field to go back, two adjacent rows get lower rates also, and the result is four (or more) rows together that all received low rates. The yield penalty is likely to be substantial. When an older manifold is used, the most important management practice is to randomize the hoses. This means that a row getting a low rate is more likely to be next to a row getting a high rate, which will minimize yield loss.

The BMP for getting even applications of anhydrous ammonia is to use a manifold that gives more even distribution of fertilizer. Cold-flow, vertical dam and Impellicone systems all give more even distribution of anhydrous than old-style manifolds. Metering applicators help control rate more accurately than free-flow systems. They also help compensate for the effects of temperature variation on ammonia pressure and delivery rate.

Boom-type spreaders for dry fertilizer are fairly reliable in their distribution patterns but sometimes have "hot spots" on the boom where higher rates are put out. It is a good idea to check evenness of boom output at least once a year to detect the need for maintenance.

One of the biggest advantages of UAN solution as an N source is the ease of making uniform applications, whether broadcast or injected. Basic attention to pressure, ground speed (compensating controllers), screens, and nozzles or orifices is all that's needed to achieve even applications.

Additives to reduce losses

There are two main additives available that help to reduce losses from N fertilizer, Agrotain and N-Serve. Both are effective at reducing the risk of N loss in certain N management systems.

N-Serve is a nitrification inhibitor that is used mainly with anhydrous ammonia. Although it can be used with other N sources, its benefits are most proven with ammonia.

Nitrification is the conversion of ammonia or ammonium to nitrate. This process happens naturally in all soils. Nitrate is the form of N that is susceptible to loss, so slowing fertilizer conversion to nitrate reduces the risk of loss. Using N-Serve with anhydrous ammonia to slow down conversion is a BMP and is especially needed when ammonia is fall-applied. (See section on N timing.) Risk of N loss is higher with fall applications than with spring applications, and N-Serve reduces but does not eliminate this risk. Even with N-Serve, fall N applications should be limited to less than half of planned corn and milo acres.

Use of N-Serve with spring anhydrous ammonia applications may also provide benefits in Missouri. Losses of N can be large in years with wet June weather, especially on poorly drained soils. Nitrate-N is lost quickly from warm, wet soils by the process of denitrification. Applying N as spring ammonia with N-Serve reduces the risk of this type of N loss.

Agrotain is a urease inhibitor that is used primarily with urea and secondarily with urea-ammonium nitrate solution. Use of Agrotain is a BMP when urea is broadcast and not incorporated with tillage or irrigation.

Urea left on the soil surface is susceptible to loss to the air, beginning on about the third or fourth day after application and continuing until at least half an inch of rain occurs. Agrotain can be coated on urea granules and is effective at delaying N loss until rain occurs.

Research shows that N loss from surface-applied urea can range from 0 to 50 percent, and 25 percent appears to be the average loss. The amount of loss depends on weather conditions; loss is greatest with warm, windy weather and a moist soil surface but is ended by rain that moves the urea into the soil. Agrotain often helps to reduce this loss and to improve yield.

Managing nitrogen from manure

Many of the same BMPs suggested for nitrogen fertilizer are relevant to manure when it is used as an N fertilizer source:

- Apply manure close to the time of crop need.

- Take care to ensure uniform spread patterns.

- Use the soil nitrate test to guide decisions about rates for additional N. This test is more useful in manured fields than nonmanured fields and can reliably indicate N availability from current or past manure applications.

- Use the corn stalk nitrate test to assess N availability for the past season. This test is the only one that can diagnose when N availability exceeded crop needs and can also diagnose when N availability was too low or just right.

- Do not apply manure in the fall until soil temperatures drop below 40 degrees Fahrenheit.

The biggest challenge to users of manure as an N fertilizer source is determining the amount of manure to apply to provide a target rate of N. Organic nitrogen ranges from 5 to 90 percent of the total N in manure. Only a fraction of that N is available in the year of manure application and some organic nitrogen is never released to plants. The rest of the N in manure is likely to be lost through volatilization if it is applied on the surface.

Organic N in manure can act as a slow-release N source, providing benefit in some situations. Poultry litter (90 percent organic N) is a superior N source for fall application on pastures when compared with commercial fertilizers such as ammonium nitrate. If conditions are good for fall forage growth, they will also be good for N release from the litter. However, in dry conditions, litter N will stay in a form that is more likely to contribute to spring growth than the more mobile ammonium nitrate.

The following best management practices specific to manure can increase the dependability and value of manure as a nitrogen source:

- Obtain a reliable estimate (lab analysis) of the nutrient content of the manure, including separate estimates of organic and total N.

- Inject low-organic-N manure sources below the soil surface when compatible with the cropping system and conservation plan. Examples of this type of manure include lagoon effluent and liquid slurry. This practice greatly increases the reliability of manure as a source of N.

- Calibrate manure spreaders to ensure that you are able to apply your target rate of manure.

- Work with a nutrient management planner to calculate the N fertilizer value of the manure. Recognize that many of the factors used to estimate N availability in manure are set in Missouri water quality regulations.

- Remember that manure is also an excellent source of phosphorus, potassium, sulfur, zinc and other nutrients. Be sure to credit manure for the full nutrient value to your crop.

Many other BMPs for manure to protect air and water quality are beyond the scope of this publication. See MU publication G9218, Managing Nitrogen to Protect Water Quality, for an introduction to some of these recommendations.

For producers with lagoon systems, timing decisions involve balancing two risks:

- The risk of N loss before uptake by the crop.

- The risk of lagoon overflow.

In these systems it is essential to have forage land available to expand the window of opportunity for manure application.

Promoting efficient uptake

Sound general crop management practices are essential to produce crops that are capable of efficient uptake of N fertilizer. The following best management practices fall within this category:

- Avoid practices that result in soil compaction. Soil compaction reduces root growth, which is critical for efficient uptake of N and for general crop health. Minimize traffic on very moist or wet soils, limit axle loads, ensure enough tire contact area on soil to support loads, and consider using controlled traffic.

- Choose good hybrids or varieties.

- Manage soil P, K and pH to ensure optimum levels for crop production. Soil sample each field at least every four years to guide P, K and lime applications.

- Carefully set planters and drills and check their performance (seed depth, spacing, soil contact and slot closure).

- Prevent weeds from getting too large. Large weeds can drain substantial amounts of N away from the crop, even if they are successfully controlled later.

Special considerations

Tillage practices influence successful management for urea and UAN solution. When tillage practices do not incorporate urea into soil, urea should be treated with Agrotain to reduce ammonia volatilization loss. When tillage practices leave substantial surface residue, UAN solution should be injected (best) or dribbled and should not be broadcast. More detail is given in the sections on sources and application methods.

The potential for nitrogen loss is greatest on soils with light (sandy) or heavy (clayey or gumbo) texture. In Missouri these soil textures are found mainly in river bottoms. Avoiding early N applications may be more important in river bottoms than in other places. Spring ammonia applications or sidedress applications of any N source will minimize the risk of N loss on these soils.

High-pH soils are rare in Missouri but can be found in the Missouri River bottom. Conversion from ammonia or ammonium to nitrate is fastest at high pH, so these soils are at greater risk for N loss. Use of BMPs in these soils is even more critical than in average fields.

Drainage systems move N to streams and rivers much more quickly and directly than natural water flow pathways. Use of BMPs for N fertilizer is especially critical on drained fields.

Acknowledgments

Thanks are due to the following individuals for reviewing this publication and providing constructive comments for its improvement:

- Sam Ferguson, Dow AgroSciences

- David Dunn, MU

- Wayne Flanary, MU Extension

- Gene Stevens, MU

- Mark Wade, chair, Plant Nutrients Committee, MO-AG, Missouri Agriculture Industries Council

- Funding for development and the initial print run of this publication was provided by the U.S. Environmental Protection Agency and the Missouri Department of Agriculture.