Land application is the primary means of using livestock wastes in Missouri. Properly spreading manure on cropland is an environmentally acceptable means of managing wastes and, at the same time, realizing a benefit from the manure's fertilizer value.

With the increased environmental concern and the need to closely match the fertilizer needs of the crop, farmers can no longer afford to just "spread manure." The land application operation should be given the same attention as spreading commercial fertilizer.

With knowledge of crop type, yield goal, soil tests and manure analysis, you can determine the needed rate of manure application. However, another critical step in obtaining this rate in the field is the correct spreader setting, operating speed and travel lane spacing.

Determining these factors is called "calibrating" the manure spreader. Calibrating a manure spreader requires measuring the weight of manure spread on a given ground area with a given travel speed, spreader setting, power take-off speed, lane spacing and other factors.

Determining manure spreader capacity

If the capacity of a manure spreader is known and the land area over which this amount of manure is spread is measured, then the application rate can be calculated by dividing the weight of manure spread by the area covered. It is important to understand the units of measurement used for manure application.

Solid or semisolid manure is usually handled in box-type or open-tank spreaders, and manure application rate is expressed in tons per acre. Nutrient concentrations in pounds per ton can be estimated, or calculated, from the laboratory analysis. Then, the nutrient application rate in pounds per acre is determined because tons per acre of manure application is known.

Liquid, or slurry, manure is usually handled by tank wagons, and the application rate is expressed in gallons per acre. Nutrient concentrations in pounds per gallon (or pounds per 1,000 gallons) are estimated, or obtained, from the laboratory analysis and used with the application rate in gallons per acre to obtain pounds per acre nutrient applied.

For calibration purposes, the capacity of a spreader in tons (for solid manure), or in gallons (for liquid manure) must be known. The volumetric capacity of spreaders is generally provided by the manufacturer. This capacity may be given as a typical "heaped" load condition or as a "struck" load condition. The struck load condition is the volume contained in the level-full box.

Caution should be exercised in using manufacturer's data for spreader volume. The standard used by most manufacturers in calculating spreader volume assumes a 60-degree angle of repose of the heaped load in the spreader. This may not be attainable with your particular type of manure or loading equipment.

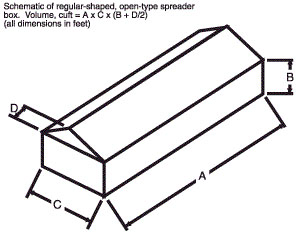

A more accurate approach may be to calculate the volume from measurements of the appropriate dimensions of the spreader box and the height of a typical heaped load. Calculate rectangular box-type spreader capacities by multiplying length by width by height and adding the volume of the heaped portion to obtain total volume (Figure 1).

Figure 1

Figure 1

Three-dimensional view of a heaped-box spreader with dimensions and volume calculations.

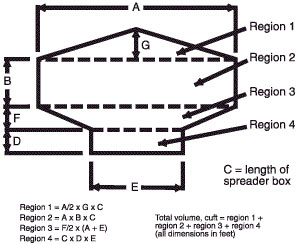

Spreaders with irregular cross sections are somewhat more complicated. However, volume can be obtained rather easily by calculating volume segments separately and adding them together for the total (Figure 2).

Figure 2

Figure 2

Three-dimensional view of a heaped-irregular shaped spreader with dimensions and volume calculations.

Closed-tank liquid manure spreaders generally have the shape of a cylindrical horizontal tank, and volume is expressed by the manufacturer in gallons. If manufacturer's data is not available, tank volume can be calculated as follows:

Tank volume, gallons = 5.87 x (tank length, feet) x (tank diameter, feet) x (tank diameter, feet)

Open-tank liquid manure spreaders may have an irregular cross section similar to some open-box solid manure spreaders. In these cases, volume is calculated in a manner similar to that shown in Figure 2. Obviously, open-box liquid manure spreaders will not have a "heaped" volume.

All liquid manure information is calculated on a per gallon basis. The computation of pounds of nutrients per load is found by multiplying the number of gallons per load by the pounds of nutrients per gallon.

All solid and semisolid manure information is calculated on a per ton basis, which requires converting from volume measure to weight measure. In order to make this conversion, the bulk density (weight per cubic foot) of manure must be known, estimated or measured. Bulk density is largely dependent on moisture content of the manure. For example, a spreader load of poultry litter at 20 percent moisture content will be considerably heavier than the same spreader load at 10 percent moisture content. Yet, volume is approximately the same in both cases.

One way to determine bulk density is to weigh the loaded spreader, then divide this weight by the spreader volume. If access to scales is available, some percentage of the loads can be weighed — one or two of every 10 loads — and all loads assumed equal to the average of the weighed loads. However, scales are usually not available on-site, and another means of obtaining bulk density is needed.

An alternate method of obtaining bulk density involves weighing a known manure volume then using this information with volumetric spreader capacity to obtain spreader capacity in tons. A five-gallon bucket is usually available, has a volume of about two-thirds cubic feet, and is a convenient known volume to use for this measurement. The following steps outline the proper procedure for obtaining manure bulk density.

- Weigh the empty bucket and write the weight on the side.

- Fill the bucket with manure. Do not compact the manure any more than might occur in the spreader.

- Weigh the full bucket and subtract the empty bucket weight. The result is the manure weight.

- Multiply the manure weight by three, then divide the answer by two. This gives the manure bulk density in pounds per cubic foot.

- Multiply the manure bulk density (in pounds per cubic foot) by the spreader volume (in cubic feet) to get the weight of the spreader load in pounds. Divide by 2,000 to get tons.

- Repeat this procedure several times. Sample the manure at different places. Average the values to obtain a representative composite of the manure.

The pounds of nutrients per load of manure are then found by multiplying the tons of manure per load by the pounds of nutrients per ton (from a laboratory analysis).

Determining application rate

Method A

The average application rate in gallons or tons per acre can be calculated if the area over which one or more loads of manure has been spread is measured.

- To measure the area covered by one spreader load:

- Mark the tractor tire by tying a piece of rope around some point on the tire. Move the tractor forward until the rope is on the ground. Mark the ground below the rope. Drive forward until the rope on the tire is on the ground again. Mark this point. Measure the distance in feet between the two marks on the ground. This is the travel distance for one tire revolution.

- Count the number of times the tire mark comes to the top of the tire while spreading a load of manure in a straight line. Multiply this number by the distance found for one revolution in Step 1a. The result is the total length of manure spreader travel while unloading one load.

- Measure the width of the spread manure path or travel lane spacing in feet.

- Multiply the width of the path by the length of travel and divide by 43,560 to get the acres covered in spreading one load.

- Calculate the manure application rate as follows:

- Divide the tons or gallons of manure applied by the area covered (in acres) to get tons, or gallons per acre. Also, divide the pounds of nutrients per load by the area covered to get pounds of nutrients per acre.

- If more than one load is spread and the areas of coverage overlap, then use the net width of the coverage between the first and last path. Use the average length of a travel path multiplied by the net width to find the area.

Method B

This method can be used to measure or adjust the application rate of a spreader without measuring the entire area of application or knowing the capacity of the manure spreader. With this method, a sheet of plastic is placed on the ground in the spreader path. The spreader is passed over the sheet at the normal operating speed. The manure is collected on the sheet and weighed. The application rate is the collected manure weight divided by the sheet area.

- Collect the spread manure.

- Select a sheet of plastic 8-by-8 feet, or larger.

- Weigh the sheet.

- Lay the sheet on the ground.

- Drive over the sheet while spreading manure at the normal operating speed. Start spreading at least 50 feet away from the sheet.

- Pick up the sheet and fold it so that you do not lose any manure.

- Weigh the sheet and manure. Subtract the empty sheet weight to determine the manure weight.

- Calculate the application rate.

- Determine the area of the plastic sheet by multiplying the width by the length in feet to obtain area in square feet.

- Multiply the pounds of manure collected by 21.78, then divide the answer by the area of the sheet (in square feet) to obtain the manure application rate in tons per acre.

Repeat the process several times and develop an average to be used as the application rate of the spreader. By conducting Method B at different travel speeds and spreader settings, the proper spreader settings and travel speeds can be determined to obtain the desired application rate.

This method does not account for overlap or space missed between spreader paths and will only give a true picture of the application rate when the manure is uniformly distributed over the field.

Table 1 shows a method of collecting data to determine manure spreader capacity.

Table 1

Manure spreader capacity

| A. Description of spreader | |||

|---|---|---|---|

| Make__________________ | Model_______________________ | ||

| Type | Box | Open Tank | Liquid Tank |

| Capacity (from dealer or measured) | |||

| Box- or open-tank | cubic feet struck load_______ | cubic feet heaped load _________ | |

| Liquid tank | gallons_________ | ||

| B. For open-tank or box-spreaders, determine the pounds per cubic foot of manure and the weight capacity of the spreader. | |||

| Type of manure | solid | semi solid | |

| 1. Determine manure density | |||

| Trial 1 | Trial 2 | Trial 3 | |

| a. Empty container weight in pounds | |||

| b. Container filled with water weight in pounds | |||

| c. Net weight of water in pound (b minus a) | |||

| d. Container volume in cubic feet (c ÷ 62.4) | |||

| e. Container filled with manure weight in pounds | |||

| f. Net weight of manure in pounds (e minus a) | |||

| g. Manure density in pounds per cubic foot (f ÷ d) | |||

| h. Average of three trials in pounds per cubic foot | |||

| 2. Weight capacity of the spreader | |||

| Struck load | Heaped load | ||

| Spreader volume in cubic feet | |||

| Multiplied by manure density in pounds per cubic foot | |||

| Equals load weight in pounds | |||

| Divided by 2,000 (pounds per ton) | _____tons | _____tons | |

Table 2 is a similar method of collecting data to measure application rate using Method A.

Table 2

Determining the application rate — Method A

- Tie a rope around a section of the tractor tire. Drive forward and mark the ground where the rope is directly underneath the tire. Continue forward until the rope is again at the bottom. Measure the distance between the two points on the ground representing the forward travel for one tire revolution.

Feet per revolution ____________. - During the spreading of a full load of manure at normal speed, count the number of times the rope on the tire comes to the top.

Number of revolutions per load ______________. - Multiply Step 1 by Step 2 to get the total distance traveled. __________feet.

- Measure the average width of the spread manure path. ___________feet.

| Measurement | 1 | 2 | 3 | 4 | 5 |

|---|---|---|---|---|---|

| Forward speed or gear/throttle setting | |||||

| PTO speed | |||||

| Spreader setting | |||||

| Width of spread manure in feet (travel lane) | |||||

| Number of revolutions (Step 2) | |||||

| Times distance (Step 1 = length of spread) Step 3 | |||||

| Width X distance in feet ÷ 43,560 = acres | |||||

| Spreader capacity in tons or gallons | |||||

| Amount ÷ area = tons of gallons per acre | |||||

| Nutrient application rate = tons per acre X pound nutrient per ton | |||||

| Or gallons per acre X pounds nutrient per gallon |

Table 3 shows the proper calculations for determining application rate using Method B.

Table 3

Determining the application rate — Method B

- Plastic sheet Width _______feet x length _______feet = area _______square feet

- Tare weight of plastic sheet and container _______pounds

| Measurement | 1 | 2 | 3 | 4 | 5 |

|---|---|---|---|---|---|

| Forward speed or gear/throttle setting | |||||

| PTO speed | |||||

| Spreader setting | |||||

| Gross weight of plastic, manure and container | |||||

| Minus tare weight | |||||

| = net weight of manure | |||||

| Divided by area of plastic | |||||

| = rate in pounds per square foot | |||||

| Solid and semi-solid tons per acre-rate X 21.78 | |||||

| Liquid gallons per acre = rate X 5,445 | |||||

| Nutrient application rate = tons per acre X pounds nutrient per ton | |||||

| Or gallons per acre X pounds nutrient per gallon |

Once a spreader is calibrated, travel speed can be adjusted to give the desired application rate as illustrated in the following example.

Example

A farmer has determined by Method A that a spreader applies manure nitrogen at the rate of 170 pounds per acre for a given spreader setting and travel speed of 3.5 miles per hour. Soil tests recommend a nitrogen application rate of 120 pounds of nitrogen per acre. How should travel speed be adjusted to obtain the desired rate?

Application rate is inversely proportional to travel speed, hence the faster the travel the lower the application rate with other factors such as spreader setting and power take-off speed remaining the same. The proper travel speed to obtain an application rate of 120 pounds of nitrogen per acre is calculated as follows:

Speed, mph = 170 x 3.51 ÷ 50 = 4 miles per hour.

Hence, a travel speed of 4 miles per hour results in the desired application rate of 120 pounds of nitrogen per acre. This method of adjusting ground travel speed to obtain a given application rate obviously would not apply to ground-driven spreaders.

Summary

Anyone spreading manure can be more certain of the amount of fertilizer being applied if a calibrated spreader is used and the nutrient content of the manure is known. Such a practice ensures that manure is being managed in an environmentally sound manner and that maximum benefit from the fertilizer nutrients in the manure is being realized.

References

- Brodie, H. L., and G. L. Smith. Calibrating Manure Spreaders. Fact Sheet 419. Cooperative Extension Service, University of Maryland.