Quick facts

- For fertilizers or pesticides to be effective, they must be applied uniformly at recommended rates.

- Equipment (sprayers and spreaders) must be calibrated to ensure adequate application.

- Misapplication wastes time, material and money, and may harm the applicant or the environment.

- Liquid application equipment should be calibrated with plain water.

- Granular applicators (spreaders) must be calibrated with the actual product.

Proper use of fertilizers and pesticides, whether of synthetic or natural origin, contributes to healthy plant growth. Applying too much may cause foliar burns or other toxic reactions in the plant. Using too little may result in damaged plants from inadequate pest control or nutrient deficiencies.

The only way to know just how much fertilizer or pesticide is being applied to the plants in your yard is to calibrate the application equipment. Calibrating an applicator is relatively simple.

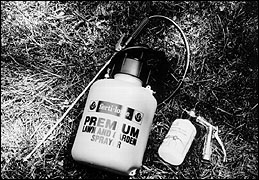

This guide outlines the steps for calibrating sprayers used for liquid applications (Figure 1) and lawn spreaders used for dry products (Figure 2). Always read and follow the product label.

Figure 1

Figure 1

Either canister sprayers, left, or hose-end sprayers, right, may be used for liquid applications of fertilizers and pesticides.

Figure 2

Figure 2

Granular fertilizers, pesticides or combination products are applied with either a rotary spreader, left, or a drop spreader, right.

Steps in calibrating a sprayer

- Adjust the nozzle opening to give the type of spray pattern desired. For hose-end sprayers, adjust the setting to the recommended dilution rate on the product label.

- Add a measured amount of plain water to the sprayer or concentrate canister. Use an amount equal to about half the sprayer's capacity.

- Pressurize the sprayer. Hand pump canister sprayers or turn water on for hose-end sprayers. Most canister sprayers do not have a pressure gauge. You can tell if you are maintaining a constant amount of pressure by the feel of the tension on the plunger.

- Spray the water onto a hard, flat surface such as a driveway. Use the same walking pace you would if applying actual pesticide. Make certain the water is applied uniformly, with no gaps and with only a small amount of overlapping.

- After the spray canister is empty, or when the concentrate container of the hose-end sprayer is empty, measure the area covered by the water.

Example

If you sprayed a band 16 feet wide by 50 feet long, you covered 800 square feet: 16 feet x 50 feet = 800 square feet. You may want to repeat steps two through five a few times until you get consistent readings.

- Calculate the amount of liquid coverage per unit area, and record that value for future reference.

Canister sprayer example

One quart of spray covered 800 square feet. That means 4 quarts (1 gallon) of spray will cover 3,200 square feet.

Hose-end sprayer example

One-half cup of water in the concentrate container covered 1,200 square feet when diluted. 1/2 cup = 24 teaspoons, so each teaspoon covered 50 square feet (1,200/24).

- Measure the area to be sprayed and calculate how much spray will be needed. Mix only the amount of chemical needed to do the job. For large areas, mark off sections with flags to break the yard up into areas no larger than can be covered by one tank full of spray.

Table 1

Useful measurements and conversions

Area

- 1 acre = 43,560 square feet

- 1 square yard = 9 square feet

Liquid measure

- 1 gallon = 4 quarts = 8 pints = 16 cups

- 1 pint = 2 cups = 16 fluid ounces

- 1 cup = 16 tablespoons = 48 teaspoons

- 1 teaspoon = 1/6 fluid ounce = 0.17 fluid ounce

- 1 tablespoon = 3 teaspoons = 1/2 fluid ounce

Quick conversions

- 1 pint per acre = 1 fluid ounce per 2,722 square feet

- 1 pint per acre = 0.37 fluid ounce per 1,000 square feet

- 1 pound per acre = 1 ounce per 2,722 square feet

- 1 pound per acre = 0.37 fluid ounce per 1,000 square feet

Liquid calibration tips

- Rate of liquid applied varies with pressure and size of nozzle opening. Maintain constant, adequate pressure. Keep nozzle clean and setting unchanged for variable nozzles.

- Avoid excessive spray overlap. Overlapped areas get a double dose. A small overlap is necessary to prevent unsprayed gaps. If good spray coverage is questionable, cut the application rate in half and apply to the same area twice at right angles to one another. Let the first application dry before applying the second.

- The spray pattern should be continuous and uninterrupted. Keep your walking rate and sprayer wand arm movement constant.

- Direct the spray pattern away from the applicator. Avoid walking through the spray.

- Never spray on a windy day. Air movement above 10 miles per hour may cause undesirable drift.

- Keep a separate set of measuring spoons and cups for pesticide use only. Do not use them for any other purpose.

- Use a separate sprayer labeled "weed killer only" or "herbicide only" for weed control products.

- Wear appropriate protective clothing. A long-sleeved shirt, long pants, rubber gloves and water-proof footwear are recommended. Protective eyewear may be necessary. Check the product label for requirements.

- On trees, shrubs and other upright growing plants, spray until the pesticide solution begins to drip from the leaves. Spray the underside of leaves as well as the top.

- Clean sprayer thoroughly after each use.

Steps in calibrating a drop spreader

- Mark off a 500- or 1,000-square-foot area on a clean, flat, hard surface such as a driveway. For example, use 10 feet by 50 feet or 20 feet by 50 feet.

- Set the opening of the spreader by following instructions in the spreader operator's manual or by following instructions on the product bag if any are given.

Note

If no settings are provided on the product bag or in the owner's manual, try adjusting the opening of the spreader to where it is slightly larger than the product particles.

- Put a known weight of product into the hopper. Ten or 20 pounds is a typical amount to use for the calibration test.

Note

If it is more convenient to apply fertilizer by volume measure than to weigh it, the conversion factors shown in Table 2, may be helpful.

- Apply the product uniformly to the marked-off area. Keep a steady walking pace. Overlap the wheel tracks from one pass to the next just enough to make certain there are no gaps in coverage or double application of the product.

- Determine the amount of material applied per 1,000 square feet using one of these methods:

- Weigh or measure the material left in the hopper and subtract this from the total added.

- Sweep up the material spread on the hard surface and weigh or measure.

Note

Sweep up and reuse the material regardless of method used.

Example

Swept up 5 quarts (= 10 pints) of 10-10-10 fertilizer from 1,000 square feet. That equals 10 pounds of product per 1,000 square feet. If the area used for calibration was 500 square feet, double the answer to get the rate per 1,000 square feet.

- If the calculated rate is not within 10 percent of the desired rate, adjust the setting accordingly and make another trial run.

Example

We want to apply one pound of actual nitrogen per 1,000 square feet. A 10-10-10 fertilizer supplies 10 percent nitrogen (the first number). Therefore, 10 pounds of the fertilizer provides 1 pound of nitrogen, which is what we want. No adjustments are necessary.

- Recheck the spreader output part way through the job to see if any minor adjustments are needed. If too little product is being applied, increase the size of the spreader setting opening. If too much is being applied, close down the opening some.

Table 2

Weight per volume relationship of fertilizer and lime

| Material | Pounds | Pints1 |

|---|---|---|

| Mixed fertilizers such as 10-6-4, 10-10-10 Ammonium sulfate (21-0-0) Muriate of potash (6-0-60) Superphosphates (0-20-0; 0-46-0) |

1 | 1 20-10-10, etc. |

| Processed manure Ureaformaldehyde (38-0-0) Urea (0-45-0) Ammonium nitrate (33-0-0) |

1 | 1-1/3 |

| Potassium sulfate, Limestone |

1 | 3/4 |

1For smaller quantities, remember 1 pint equals 2 cups or 32 level tablespoons.

Steps in calibrating a rotary spreader

- Test the distribution pattern of the spreader by lining out a row of 10 or 12 low, flat boxes on a hard, flat surface. With the spreader partially filled and set to the desired opening, make three passes over the boxes. Go the same direction each time.

Note

Twenty-four-can soda boxes are about the right size to use. Space the boxes uniformly across an area slightly wider than the spreader throws the product. Measure the distance between boxes, and make a note of it.

- Pour the material caught in the boxes into separate small jars or cups. Line the containers up in order side by side to see the distribution pattern.

Note

In most cases, the containers in the middle will be fuller than those on the edges. Remember to sweep up and reuse the material not caught in the boxes.

- Use the pattern to determine the approximate amount of overlap needed on each swath to get a uniform application rate. The smaller amounts collected on the edge of the pattern can be overlapped or combined to equal the amount applied in the middle of the pattern.

- Determine the effective swath width of the spreader. The total width of the granule distribution pattern minus the overlap needed on one side gives the effective swath width.

Example

If the total width of granules is 15 feet, but we need to overlap by 3 feet to get a uniform pattern, the effective swath width is: 15 feet - 3 feet = 12 feet. - Follow the calibration steps outlined above for drop spreaders. In marking out the 500- or 1,000-square-foot area for calibration, use a width equal to one or two times the effective swath width.

Example

For an effective swath width of 12 feet, you might use an area 24 feet by 41-2/3 feet to make 1,000 square feet.

Granular calibration tips

- Drop spreaders are more precise. There is little chance of product application to non-target areas. However, small steering errors can easily lead to missed or double-covered strips. Also, drop spreaders may clog in wet grass.

- Rotary spreaders are faster than drop spreaders but are more difficult to calibrate. Product distribution is less uniform, and wind may blow the product off the intended area.

- The application rate for granular spreaders depends on the granule size, the spreader setting and the speed at which the operator walks.

- Spreader calibration must be done for each product and applicator who uses the spreader.

- Always sweep up and reuse the product used for calibration.

- Use a header strip in areas where the spreader must be turned around. A header strip is a swath of the spreader applied at right angles to the main direction of spreading. This allows the applicator to maintain constant speed up to the header strip.

- Shut the spreader off while turning around on the header strip.

- Wash the spreader out after each use. Allow to dry before storing. Lubricate according to manufacturer's instructions.

Partial funding for this publication provided by U.S. EPA, Region VII.