Aquaculture is the general term used to describe the propagation and rearing of aquatic animals and plants in controlled or selected environments. It is not a new concept as many civilizations farmed fish for food and recreation prior to 2000 BC. Throughout history, ponds were constructed and fish were raised in the same manner as fish are produced today.

Both freshwater and saltwater fish are raised commercially throughout the world. Other related aquatic products raised commercially are shrimp, oysters, clams, worms, crickets, frogs and some aquatic plants.

The popularity of aquaculture is increasing in the U.S. However, the majority of fisheries food products consumed here are either imported or are captured wild stocks from natural waters. Aquaculture products can be an answer to the growing problem of world dietary animal protein shortages. Fish convert feed into flesh about two times more efficiently than chickens and five to ten times more efficiently than beef cattle. Feed conversion rates of fish are higher than common commercial livestock because:

- Fish can utilize foods that are less usable by most land animals, and

- Fish require less energy from their foods.

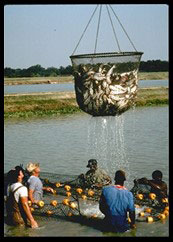

Moreover, fish can use the entire pond, top to bottom, for living space; terrestrial animals are confined to the ground. The proper combination of fish species, control of the environment and careful feeding can result in annual yields approaching 6,250 pounds per acre of pond water, compared to approximately 1,000 pounds per acre yield from beef cattle production. Pond production can also utilize cage culture techniques to raise fish for various markets (Figure 1a, b, c and d).

Figure 1a.

Figure 1a.

Figures 1a, b, c and d. Watershed ponds and those designed with earthen levees are examples of pond culture systems, such as those used in the southern United States and in many locations of Missouri. These ponds can be managed at varying levels of intensity, including producing large quantities of food fish or on a smaller-scale for other aquaculture products. A variety of production techniques have been shown to be effective for producing fish using pond culture.

Figure 1b.

Figure 1b.

Figure 1c.

Figure 1c.

Figure 1d.

Figure 1d.

New aquaculture technologies allow more intensive outdoor and indoor culture to produce fish and salt-water shrimp (Figure 2a, b and c). Intensively aerated outdoor ponds can support yields of 10,000 to 15,000 pounds per acre of catfish production. Zero-discharge, climate controlled, indoor systems have demonstrated yields of more than 40,000 pounds per acre of water. Indoor systems support increased yields by simulating the growing conditions and water quality needed to culture the aquatic species. The potential for increased production and profits has stimulated interest in fish farming and aquaculture.

Figure 2a.

Figure 2a.

Figures 2a, b and c. Intensive indoor culture systems have been developed which utilize technologies designed for producing fish and other aquaculture products. Specific equipment is necessary to maintain water quality, eliminate wastes and discharge, and for feeding appropriate amounts for optimum fish growth.

Figure 2b.

Figure 2b.

Figure 2c.

Figure 2c.

Aquaculture, however, is a highly specialized form of agriculture. It is a high-risk enterprise. Animals cannot be easily observed in their water environment, particularly in pond culture. Producers may be unfamiliar with water quality management and understanding the biology of the aquaculture species. There are numerous expenses to consider and potential markets to be investigated. Consequently, to increase potential for success, it is important to research and carefully plan a aquaculture venture before getting started.

Aquaculture in Missouri and the U.S.

Aquaculture is important in Missouri in both public and privately owned waters. Examples of public aquaculture include warm-water and cold-water hatcheries that rear and produce a variety of species for stocking lakes, rivers and streams.

Private aquaculture enterprises are businesses producing fish and aquaculture products for a variety of markets, including those produced for recreational stocking in privately owned ponds and lakes, fish processed for food markets, and specialty fish such as baitfish and ornamentals. Species produced include channel catfish, largemouth bass and other sunfishes (i.e., bluegill, red-ear, hybrid bluegill), hybrid striped bass, rainbow trout, freshwater prawn, saltwater shrimp, carp, and numerous species of baitfish.

The U.S. aquaculture industry in 2019 had a value of $1.5 billion. The largest single U.S. aquaculture sector is Southern catfish with sales of $377 million. In comparison, Missouri aquaculture remains a smaller industry with sales of about $12.7 million coming from 80 farms (about $160,000 per farm). This contrasts with about 46,000 Missouri cattle farms yielding sales of $1.9 billion (about $41,000 per farm).

The states of Mississippi and Washington lead U.S. aquaculture production. In 2018, these states both produced more than $200 million in aquaculture products. Aquaculture sales in the U.S. are dominated by catfish and trout production. From 2017 to 2019, trout producers in 15 surveyed states sold 42.2 million pounds of food-size trout valued at 81.7 million dollars ($1.94 per pound). During the same period, U.S. catfish growers sold 342.9 million pounds valued at $352.7 million ($1.03 per lb.). Southern catfish production yields increased from 4,087 lbs per acre in 2010 to 5,738 pounds per acre in 2020 as a result of industry efforts to intensify production.

Trout production is dominated by Idaho growers. Three large producer-processors control the majority of the frozen and processed trout market. Fortunately, producers in other states have seen prices increase and expect prices for fresh and live trout to continue to climb.

Establishing an aquaculture business enterprise

Figure 3. Important aspects to consider when developing an aquaculture business.

Figure 3. Important aspects to consider when developing an aquaculture business.

Step 1: Planning stage

Planning involves evaluating the biological, economic, market, financial and management feasibility of raising a particular fish, group of fishes, or other aquaculture products (Figure 3). Potential constraints that may exist for each of these feasibility factors are important to consider as well.

Economic feasibility

An aquaculture venture is economically feasible if a fish or aquaculture product can be produced at a cost competitive with other sources and can be reasonably profitable. Operating and ownership costs affect an aquaculture enterprise’s cost of production. Examples of these factors can be outlined as follows:

| Category | Examples |

|---|---|

| Capital investments (upfront) | Land, buildings, equipment (e.g., tanks, filters, pumps, nets, lifts, processing), water source development, power source development, farm vehicles and construction costs. |

| Operating costs (annual) | Fish stock (eggs, fry, fingerlings), feed, labor, chemicals (disease control, water chemistry analysis), treatments, oxygen, vaccines, utilities, repairs and maintenance, miscellaneous supplies, delivery to market, interest on operating capital. |

| Fixed costs (annual) |

Management, depreciation/taxes/interest/insurance on real estate and equipment. |

Aquaculture ventures can be extremely labor intensive. Labor cost and availability can be limiting production factors for U.S. firms. Less labor-intensive aquaculture ventures can be limited by high feed costs. Labor and feed tend to be some of the higher operating costs within an aquaculture business.

Processing is a production cost if existing processing facilities are not available, or a producer is unable to sell products to a processor at a reasonable profit. Processing costs (as well as state and federal processing regulations) can be constraints that affect perspective aquaculturists.

In the U.S. north central region, a minimum of $200,000 would be required to start a trout production farm capable of supporting an operators' income requirements. Lower levels of investment will usually limit income and may result in negative profitability. Current trout producers who aggressively market their products typically have little difficulty selling fish. Other types of aquaculture operations can cost less. Starting a fee-fishing operation may require an initial investment of $30,000 to $50,000. A bait minnow farm may require $60,000 to $80,000 of initial investment. On the other hand, starting an intensive indoor aquaculture facility with fish production capacity of 40,000 to 80,000 pounds per year can cost more than $300,000 to establish.

An example budget (Table 1) is provided for an indoor system producing 40,000 to 80,000 pounds of fish per year (in an 80,000-gallon system). Smaller systems would have a higher initial capital cost per pound of production. The building cost reflects a new building. This capital investment value would be less if an existing building were purchased or it has potential to be zero if a building were rented (though rent payments would be an operating cost instead). Costs are shown in terms of fish cultured at a lower density and fed a higher protein feed (such as largemouth bass), and fish cultured at higher density and fed a lower protein feed (such as channel catfish). In both cases, the food conversion ratio is assumed as 1.5/1, and fish survival is assumed at 85% of stocked number. Break-even costs for the indoor system are projected to range from $3.78 to $4.21 per pound. This example illustrates the need to seek direct retail sales with higher selling prices to ensure operation profitability with an indoor system.

Table 1. Sample Budget (costs in this sample budget are illustrative only).

| Cost | Medium/High Density System Cost ($ per pound) | |

|---|---|---|

| Fixed Costs | Medium | High |

| Building | 0.23 | 0.12 |

| Climate control | 0.11 | 0.06 |

| Tanks | 0.18 | 0.09 |

| Aeration | 0.08 | 0.08 |

| Biofilter | 0.07 | 0.07 |

| Solids filter | 0.06 | 0.06 |

| Generator | 0.04 |

0.04 |

| Pumps | 0.01 | 0.01 |

| Total fixed costs | 0.78 | 0.53 |

| Variable Costs | Medium | High |

| Fish | 0.78 | 0.78 |

| Feed | 2.29 | 1.47 |

| Energy | 0.50 | 0.36 |

| Labor | 0.64 | 0.64 |

| Total variable costs | 4.21 | 3.25 |

| TOTAL COSTS | $4.99 | $3.78 |

Market feasibility

Marketing represents an important consideration for aquaculture businesses. It involves developing a good that meets consumers’ needs and then choosing an appropriate price point, distributing the product in market channels that reach targeted consumers and promoting the product to build awareness and drive sales.

To assess the marketing feasibility of a business concept, aquaculture producers should undertake the following activities.

- Summarize the product concept.

- Identify potential product buyers.

- Study target buyers’ product needs and purchase considerations.

- Choose market channels that effectively reach target buyers.

- Evaluate need for intermediaries (e.g., processors, distributors, wholesalers, retailers) to get involved in producing your product or connecting your business with buyers.

- Assess competitors and barriers to entry in the marketplace.

- Understand product pricing trends and opportunities in each market.

- Estimate potential product demand and volume by market channel.

- Consider product packaging options.

- Outline opportunities to promote your product.

Aquaculture producers may supply varied products to different types of buyers. For example, individuals or organizations that manage recreational fish ponds may purchase live fish, and retail food stores and restaurants represent markets for processed food items. Buyers make decisions about aquacultural items to purchase based on quality, cost and service. Aquacultural businesses often choose to compete on cost or pursue a differentiation strategy that involves adding value to raw materials to yield a unique final product.

In addition to demanding different products, market channels also vary in complexity. Choosing a more complex market channel — for example, one that involves wholesalers or distributors instead of selling direct to buyers — means a product changes hands more frequently. The intermediaries involved lend their expertise and capacity, but by engaging these other businesses, the farm has a lower likelihood of capturing the majority of a product’s retail value. By bypassing intermediaries, the farm assumes more responsibility for creating the final product and marketing it. This will increase costs and risk but give farms a chance to capture more value.

Small or start-up aquaculture producers may have to process and market their own products at first. Over time, business networks may develop and create more opportunities for these producers to engage intermediaries and focus their attention on production. To incentivize an intermediary to work with an aquacultural business, the producer may need to ensure a continuous, year-round supply of marketable fish. Until year-round production is possible, a processor or business may hesitate to invest in or handle an aquacultural product because seasonal supplies may restrict market development. To avoid slack production periods, processors prefer to buy fish from producers on contract.

Potential market channels for a new aquaculture business could include direct-to-consumer channels such as farmers markets, on-site stores or online markets; direct-to-retailer arrangements such as direct-to-store sales, institutional marketing or restaurant sales; or broker-, wholesaler- or distributor-assisted sales. Table 2 summarizes market channel key features. Note, serving multiple market channels enables an aquaculture business to diversify and manage market risk by not leaning too heavily on one particular channel.

Table 2. Missouri aquaculture market channel features.

| Market channel |

Farmers market |

On-site store |

Brokers, wholesale or distributors |

Direct-to-store sales |

Institutional marketing |

Restaurant sales |

Online market |

|---|---|---|---|---|---|---|---|

| Suitable for large volumes of product | No | No | Yes | Yes | Yes | No | No |

| Marketing time involved | High | Medium | Low | Medium | Low | Medium-high | Medium |

| Degree of grower contact with consumers | High | High | Low | Low | Low | Low | Low |

| Price stability | Medium | Medium | Low-medium | High | High | Medium-high | High |

After choosing a market channel and the audience to target, aquacultural businesses may project product demand. Demand hinges on the amount of product consumers will purchase, a product’s selling price, the competitive environment and the market share a product can capture.

Biological feasibility

It is advisable to determine the biological feasibility of raising the desired fish or aquaculture products in a particular area. Not all fish or aquaculture products are suitable for culture in every area. In Missouri, the growing season widely varies from the bootheel region up to northern areas. Water temperatures can restrict growth rates and promote seasonal yields. Environmental constraints (such as water quality, water temperatures, and the length of the growing season) dictate where an aquatic organism can be raised commercially.

Water supply

Water supply is critical when selecting the site of an aquaculture facility. Desirable water supply characteristics include:

- Relatively constant flow

- Constant or acceptable water temperatures

- High levels of dissolved oxygen

- Low levels of harmful gases

- Low siltation levels

- Limited possibilities of introducing diseases or wild fishes

- No chemical or organic pollution sources.

Based on these characteristics, water supply sources can generally be ranked (from most to least desirable) as springs, wells, streams, lakes and reservoirs. Many ponds constructed in Missouri are watershed ponds that rely on surface-runoff to maintain the water supply of the pond or impoundment. These water sources may experience seasonal fluctuations due to drought and may not be reliable. Surface runoff and groundwater may also be unacceptable sources of water for commercial production ponds because of possible pollution.

The point is that any potential water supply source should be adequately tested, both for quantity and quality, before making any facility cost analysis. For example, raising shrimp, lobsters or other tropical marine animals inland, is technically feasible, but would require climate-controlled, zero-discharge, indoor production (in the Midwest) to avoid costs of salt supplementation and disposal.

Water temperature and growing season

Water temperature and/or the length of the growing season often limit commercial production of aquatic organisms. Each type of aquatic animal requires a specific growth-promoting water temperature. For example, trout require lower water temperatures than channel catfish for optimum growth.

An aquatic organism’s body temperature is approximately the same as the water temperature. Water temperature thus affects its activity and growth. Therefore, the water temperature must meet the organism’s growth needs during a significant portion of the year. Temperatures below the organism’s optimum level prolong the time for the aquatic organism to reach market size, raising production costs. Temperatures above the optimum level for growth will stress the aquatic organism and result in reduced growth, disease and often death.

Water temperature is one reason that catfish production for food markets is severely limited in the northern part of Missouri. The growing season (water temperature above 65 F) is too short, and up to three years may be required to produce a marketable catfish. Only 18 to 24 months is required to produce a harvestable catfish in the southern U.S., where the growing season is longer. In addition, eggs, fingerlings, feed and other production supplies may not be locally available. Bulk shipping costs for fresh and frozen catfish from the southern U.S. range from about three percent of catfish farm gate income to as high as 10 percent for small-scale operations (less than 5,000 pounds per year) distributing to local markets. Because of temperature limitations, most of Missouri catfish production must either meet demands for specialty niche markets or compete in price with southern produced catfish.

Biological constraints

Although fish (and other aquaculture species) have higher feed conversion rates than most terrestrial animals, not all fishes are suitable for intensive culture. Additional biological constraints limit which aquatic organisms can be raised at high densities commercially. Lack of knowledge of the reproductive biology, nutrition and diseases of specific aquatic organisms represents the major constraint upon the culture of certain aquatic animals.

Reproductive biology

The reproductive biology of cultured aquatic organisms must be well understood before undertaking commercial production. Controlling reproductive biology is essential for commercial culture. Culture of wild captured stocks (which may be illegal, depending on the species) is entirely dependent on the unpredictable availability of wild fry or seed. The aquaculturist’s control over the aquatic organism’s reproductive biology allows for the desired timing and quantity of aquatic offspring. For example, lack of reproductive control is one of the major constraints limiting shrimp culture in coastal areas.

Nutritional requirements

Nutritional requirements represent a major factor in determining the suitability of an aquatic species for aquaculture. As mentioned, prices of feeds based on rigid formulations can fluctuate severely with availability. This problem can be avoided by understanding the nutritional requirements of an aquatic organism, which can then allow potential substitution of ingredients.

The nutritional requirements of some fish species and other aquatic animals may not be well understood. This is even true for fish currently under intensive commercial culture, such as trout and channel catfish. Furthermore, some fish and aquatic animals require natural feeds such as algae, insects and minnows. If these animals are raised commercially, these natural feeds must be raised as well.

Disease resistance and control

A third biological constraint to aquaculture is disease resistance and control. Aquatic animals raised intensively are crowded into a limited area, which tends to promote disease spread. If diseases cannot be quickly identified and treated, the entire stock can be lost in a few days. The potential of disease-caused disasters to aquaculture mandates knowledge of diseases and their prevention and control.

Scientific advances in the areas of reproductive control, nutrition and disease control will improve the potential for aquaculture of established and new aquatic species. Selective breeding and advanced systems technology will help eliminate many of the biological constraints on aquacultural development.

Financial feasibility

Financial feasibility is focused on how much start-up capital is needed, sources of capital, returns on investment and other financial considerations. In other words, it looks at how much cash is required, where it will come from and how it will be spent. These are components to include in evaluating financial feasibility.

- How many dollars do you have available to invest in the aquaculture business?

- What is the availability and reliability of capital financing?

- Are cost-share or grant opportunities available for the business?

- Are there investors or other parties available to provide capital?

Sources of loan financing include commercial banks, Farm Credit System institutions and the USDA Farm Service Agency. Private sector loan financing is generally conservative. Rarely will the private sector be persuaded to finance projects where risks are high, profits uncertain, and past experiences to guide decisions unavailable. Additionally, these firms will want to see a detailed business plan, financial projections and sufficient equity provided from the aquaculture business. It is recommended to visit with financial institutions well in advance to understand if they might be a source of financing the aquaculture business.

Some longstanding U.S. Department of Agriculture programs (cost-shares, grants, loans) have been expanded to include aquaculture. Visit your local USDA service center to see what programs might be used to assist or capitalize your aquaculture business project.

Management feasibility

Management feasibility focuses on the human resources and legal components of the business. In other words: Can we have an efficient labor workforce, provide necessary management, and comply with state and federal laws? Desirable qualities in an aquaculture business manager include fish production experience and knowledge, engineering, computer control systems and marketing. Good communication and human resources skills are essential, as is a commitment to learn needed skills.

In terms of legal components, Missouri does not require a permit to raise fish for aquaculture purposes. A “bill-of-sale” documenting the purchase of fingerlings or other farm-raised fish for stocking is required. However, the Missouri Department of Conservation does have an “Approved Aquatic Species List” identifying the various aquatic species that can be legally produced in outdoor culture. Indoor culture may allow for other species, not allowed in outdoor culture, to be legally produced in Missouri.

Various other local, state and federal laws can restrict aquacultural development. These fall into several categories including:

- Land use laws

- Access laws

- Water use laws

- Environmental laws

- Transport laws

- Health and food safety laws

- Transportation permits to markets in-state and out-of-state

- Other permit procedures and requirements.

Permits required to establish an aquacultural business vary by situation. A list of Missouri policies and regulations pertaining to aquaculture is provided by the North Central Regional Aquaculture Center.

Prospective Missouri aquaculture producers should contact the Missouri Department of Natural Resources and the Missouri Department of Agriculture for more detailed information. Permitting may take considerable time and planning. For example, permits to release effluents from an aquaculture facility may be denied if effluents are released into a high-quality trout stream. Choosing an alternate site where effluents can be discharged into a less sensitive receiving system may facilitate obtaining the necessary effluent permits.

Aquaculture processors have local, state and federal requirements for starting a food business. Missouri processing facilities are regulated under the Missouri Department of Health and Senior Services (DHSS). Processors that do not provide food directly to consumers should contact DHSS’ Manufactured Food Program, who will perform inspection. Those providing retail food come under the jurisdiction of DHSS and local public health agencies to provide oversight and inspection. Good manufacturing practices, food safety plans, training, labeling and recordkeeping are some of the components that may be needed to be in compliance.

Step 2: Training stage

Aquaculture production requires a different set of technical and managerial skills than other agricultural activities. A person needs specialized training in water quality management, aquatic weed control, parasite and disease control, nutrition and feeds, cultural techniques, marketing, and processing skills. An informed aquaculturist can minimize potential risks of raising aquatic organisms; the untrained fish farmer may continually face the possibility of unpredictable disaster.

The necessary technical and managerial skills required for aquaculture can be gained by enrolling in various college and university courses on these topics; attending Extension educational programs, workshops and other activities that feature these topics; and by accessing research-based information from reliable sources (such as land-grant universities and USDA Regional Aquaculture Centers).

Aquaculture skills can also be gained by hiring consultants (such as a fisheries biologist trained in fish culture), by working with an existing aquaculture business to gain experience, or by networking with members of the Missouri Aquaculture Association. Previous work at an aquaculture business is highly advisable. First-hand, experiential learning will give the potential aquaculturist insight into the daily workings of an aquaculture operation.

Regardless of the method used to obtain technical and managerial skills, such skills are necessary in the process of establishing a commercial aquaculture venture. Once the skills are acquired, the prospective aquaculturist can proceed to Step 3.

Step 3: Pilot test

A small-scale pilot test is desirable (particularly when evaluating a new species or culture technique) to determine the validity of estimates made during the planning stage. The pilot test can minimize potential losses by identifying if the initial planning stage studies overestimated the project’s biological feasibility or the product's acceptability, or if the economic outlook or marketing opportunities have changed. A small pilot project also permits the new aquaculturist to develop practical managerial skills.

A pilot test can also provide experience that can minimize later failures resulting from lack of experience. However, small pilot operations cannot be used to directly analyze economic feasibility because of economy of scale. Many inputs, such as feed, chemicals and fish equipment can be purchased at a discount when ordered in bulk. Many attempts at large scale commercial fish culture have failed because of undercapitalization and the consequent inability to take advantage of the economies of scale.

Only after the pilot project verifies the feasibility of the proposed commercial aquacultural venture—and the aquaculturists have obtained and developed their skills—should a full-scale commercial operation be undertaken, Step 4.

Step 4: Commercial operation

The size and nature of a commercial aquaculture venture will depend on positive results obtained from Step 1, Step 2 and Step 3.

Some people interested in aquaculture progress to stage three and decide to restrict the size of their operation. A small-scale operation can help diversify their farming activities and provide a rewarding supplemental income. Their businesses can also grow over time as aquaculturists build confidence in their production skills and markets evolve for their aquacultural products.

Very few aquaculturists proceed to Step 4 and develop a large-scale operation. Large-scale commercial aquaculture are often located in regions where biological requirements are best met, where markets for fish products are established, where processing and distribution networks are available, and where the price of a cultured species can compete favorably with prices of captured wild fishes. In the near future, the lack of a national network of processors, distributors and markets will continue to limit the growth of large-scale commercial aquaculture outside already established regions.

The future of aquaculture in Missouri, the North Central Region and in the U.S.

The potential for aquaculture is theoretically very high, but a number of factors (such as water pollution) threaten aquaculture expansion. However, widespread interest in aquaculture, anticipated funding and developmental support through the USDA Regional Aquaculture Centers and land-grant Extension programs, and advances in technology and scientific knowledge, will have a positive effect on aquaculture’s potential in Missouri and throughout the region.

Aquaculture checklist

Aquaculture can be a rewarding and profitable business opportunity under the right conditions. Like other forms of farming, aquaculture production involves substantial capital investment and many risks. Growing fish or other aquaculture products requires specialized training and daily attention. If you are considering aquaculture, this checklist can help you determine whether this enterprise is feasible for your particular situation. The checklist does not cover all possibilities, so answering "yes" to most of the questions will not guarantee your success. Answering "no" to many of the questions will not mean automatic failure. The checklist does present many of the most important considerations. To have a good probability of success, most of your answers should be in the "yes" column.

Market

| Yes/No | Criteria |

|---|---|

| ❑ | Is there an established market for your fish or aquaculture products? |

| ❑ | Is there a market and demand for your products when you plan to sell them? |

| ❑ | Will products be available year-round if so required by the market? |

| ❑ | Are their similar products available at prices lower than your profitable selling price that will out-compete you in the market? |

| ❑ | Do you have an alternative market on which to fall back? |

Management

| Yes/No | Criteria |

|---|---|

| ❑ | Do you have land with suitable water supplies and sites for fish culture development? |

| ❑ | Do you have machinery and equipment needed to raise, process, and market fish? |

| ❑ | Do you have the necessary financial resources to invest in the aquaculture business? |

| ❑ | Are estimates of costs and returns available for this aquaculture enterprise in your area? |

| ❑ | Is the profit potential from raising fish or other aquaculture products higher than that of other possible investments? |

| ❑ | Will the expected profit be adequate compensation for your labor, management, and risk? |

| ❑ | Are financial institutions or banks willing to loan money for aquaculture in your area? |

| ❑ | If you are using debt financing, will the current interest rates permit a reasonable profit? |

| ❑ | Is aquaculture the best alternative for the land you intend to use? |

| ❑ | Can you afford to forego income until you sell your first crop? |

| ❑ | Are you able to absorb occasional production losses? |

| ❑ | Are you willing and able to devote the daily time and effort required? |

Physical factors

| Yes/No | Criteria |

|---|---|

| ❑ | Do you have enough water volume to raise the fish or aquaculture products you would like to grow? |

| ❑ | Do you have the water quality necessary to raise the species you would like to grow? |

| ❑ | Does the land have appropriate topography for the construction of ponds or raceways? |

| ❑ | Will the soil hold water? |

| ❑ | Is the area protected from flooding? |

| ❑ | Can you build a water retention area to remove waste products? |

| ❑ | Can you discharge water from your site? |

| ❑ | Do you live close enough to the site to allow frequent and timely observations of the fish? |

| ❑ | Is the site easily accessible year round for you and transport trucks? |

Production factors

| Yes/No | Criteria |

|---|---|

| ❑ | Are eggs or fingerlings available from dealers at competitive prices? |

| ❑ | Can you raise your fish from eggs to produce your own fingerlings? |

| ❑ | Are high quality fish feeds readily available at competitive prices? |

| ❑ | Do you have a suitable area to store feeds? |

| ❑ | Do you have a source of the drugs and chemicals needed? |

| ❑ | Is dependable labor available? |

| ❑ | Are dependable diagnostic services available locally? |

| ❑ | Are university aquaculture experts, government agencies, or professional fish consultants available to provide educational and technical services? |

Risks — Are you equipped to handle the following problems:

| Yes/No | Criteria |

|---|---|

| ❑ | Poor water quality? |

| ❑ | Fish disease and parasites? |

| ❑ | Poachers and vandals? Predation from a variety of mammals and birds? |

| ❑ | Potential chemical contamination? |

| ❑ | Business management and taxation? |

These are the elements essential to a successful fish farming enterprise:

- Large volumes of high-quality water.

- Suitable water quality.

- Sufficient financial resources.

- Established markets.

- Appropriate management skills and time.

What fish can you grow in Missouri?

Here is a list of candidate fish or other aquatic animals and their current potential for culture in Missouri. As discussed earlier, Missouri has an “Approved Aquatic Species List” provided by the Missouri Department of Conservation that provides information on fish that can be legally produced for aquaculture in the state.

| Candidate | Current NCR culture potential | Comments |

|---|---|---|

| Rainbow trout, brook trout, brown trout | Low to high | For food and stocking private lakes and ponds: These fish require high quality cold water. They can be raised in raceways where large volumes of water are available or in ponds during the winter months using cage culture techniques. |

| Largemouth bass, smallmouth bass, bluegill sunfish, hybrid sunfish, crappies | Moderate to high | For stocking private lakes and ponds: market may be saturated in some areas. For food: potential markets exist. |

| Baitfishes | Moderate to high | For local bait fish industry demand and especially for periods of seasonal supply shortages. |

| Walleye, yellow perch, striped bass hybrids | Moderate | For stocking private lakes and for food: Fingerling or broodstock supply may be limited, culture techniques under development. |

| Crayfish | Moderate | For bait and food: culture techniques under development. |

| Common carp, aquarium fishes, goldfish | Low to moderate | Limited markets |

| Grass carp | Low to high | For aquatic plant control: illegal to possess diploids or any grass carp in some NCR states. |

| Channel catfish | Moderate to high | For food and stocking: difficult to compete with supplies from the southern states. Require warm waters for food fish growth. |

| Aquatic plants (wild rice, water cress, water lily, etc.) | Low | For food or ornamental water gardening: limited markets. |

| Tilapia | Low | Not on the “Approved Aquatic Species List” so must be raised so that they are unable to be released into other waters. Must contact the Missouri Department of Conservation for permission. For food: limited market, usually raised in in-door recirculating systems as they do not tolerate cooler water conditions. |

| Freshwater shrimp (prawns) and Saltwater shrimp | Low to high | Prawns produced in ponds are a seasonal market and limited. Saltwater shrimp can be produced in in-door systems but some markets are poorly defined or don't currently exist. |

Resources

- University of Missouri Aquaculture and Fisheries Extension Program

- Lincoln University Aquaculture Extension

- USDA North Central Region Aquaculture Center

- USDA Southern Region Aquaculture Center

- Missouri Aquaculture Association

- Missouri Department of Agriculture (See the "Missouri Aquaculture" section.)

- Small scale marketing of aquaculture products (PDF). Southern Regional Aquacenter, 2009.