Cattle manure can be handled as a solid, semisolid, slurry or dilute liquid. Freshly excreted manure from cattle in a feedlot is a semisolid, typically containing 85 to 88 percent moisture on a wet basis. Manure from cattle on succulent pasture may be a thin semisolid. Adding a significant amount of bedding (straw, corn stover, etc.) or draining off a portion of the liquid can convert the manure to a solid material that will stack. The manure can then be handled with conventional equipment (front-end loaders and beater-type spreaders).

Slurry manure contains the solid and liquid portions of cattle manure and has a fluid consistency. Slurry manure contains little or no bedding and is usually collected in manure tanks, either aboveground, or sometimes under slats. Pumps and tankwagons are required for the handling and spreading of slurry manure because of its fluid characteristics. Cattle manure collected and treated in a lagoon is highly fluid and is best handled with irrigation equipment.

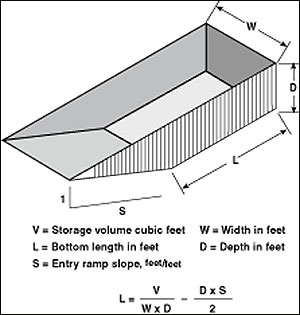

Figure 1

Figure 1

Picket dams provide storage for manure while allowing water to drain away.

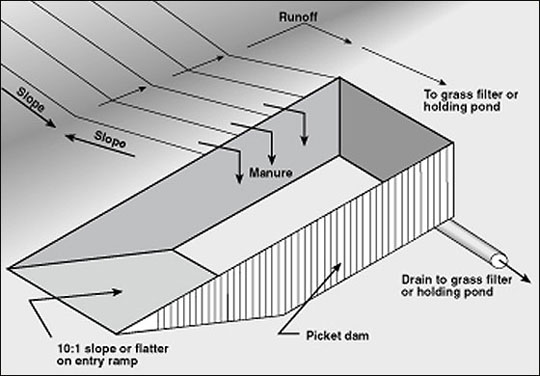

Figure 2

A concrete trough collects runoff that drains through this picket dam.

Semisolid cattle manure may contain small amounts of bedding or other material, such as waste hay or silage, and can usually be handled as a solid if no additional water is allowed to collect or mix with the manure. Picket-dam facilities have proven useful for storing semisolid manure (Figures 1 and 2). Their design allows excess water from rainfall or other sources to drain away so that the material can be handled with conventional equipment. Manure cannot be expected to "dry out" or de-water in a picket-dam facility. The picket dam is effective only in draining away free water, such as rainfall or runoff water from the manure. Adding about 1 pound of dry straw or corn stover per day per 1,000 pounds of cattle animal to the manure can lower the moisture content of as-excreted manure from 88 percent to about 86 percent moisture content, the "mid range" for semisolid cattle manure.

Advantages of a picket dam

Several advantages have been noted in the use of picket-dam storage structures for cattle manure.

- Handling manure as a semisolid in a picket-dam facility allows the use of conventional manure equipment such as front-end loaders and beater-type manure spreaders.

- Other solid manure containing bedding, such as manure from maternity or sick pens or other pens and shelters, can be handled in the same facility.

- Handling manure as a semisolid and draining away excess water from rainfall or other sources reduces the total volume of material that must be hauled.

- A picket-dam storage structure can be built to accumulate manure for several weeks or months. Such a storage period allows flexibility in the manure-hauling schedule, and daily hauling is not required.

Requirements for a picket dam

Certain management techniques are necessary to ensure best performance from a picket dam.

- Small to moderate amounts of bedding or waste forage are needed in the manure. A small amount of bedding gives the manure a semisolid consistency without being too fluid. Semisolid manure will "slump" away from the loading point so that more manure can be added to the storage. Picket dams are frequently used for dairy manure where the small amount of bedding normally kicked out of freestalls usually results in manure of the proper consistency for picket-dam storages, if no other water is allowed to mix with the manure.

- To the extent possible, surface runoff from lot areas should be directed to a lagoon, holding pond or appropriate grass filter, and not routed through the picket-dam storage. This will help the manure retain the ideal semisolid consistency.

- Rainwater falling directly on the picket-dam storage should be drained away. This is accomplished by proper design of the facility.

- Experience has shown picket-dam facilities to be best suited for small to moderately sized operations, since manure handling is somewhat labor-intensive. Larger livestock operations generally employ other means of manure collection and transport requiring less labor.

Figure 3

A picket dam facility with a slight dip in the approach can intercept runoff water and direct it around the facility.

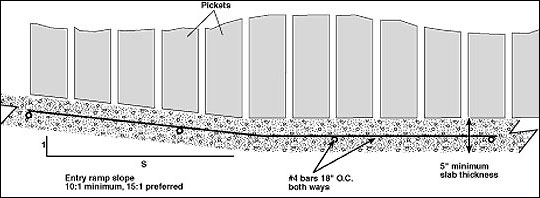

Figure 4

Side view of a concrete entry ramp with 10:1 slope.

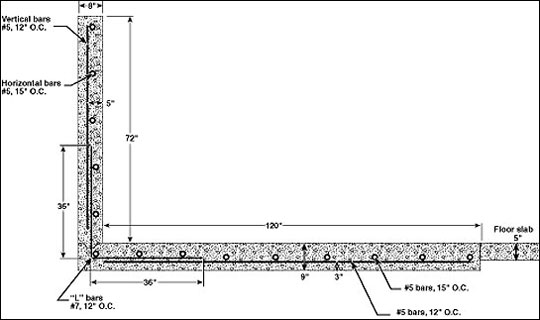

Figure 5

Design for a six-foot free-standing concrete wall.

Design considerations

Several design considerations and requirements are necessary to optimize performance of the facility.

- Loading

Loading a picket-dam storage facility is usually accomplished by scraping and pushing manure into the facility by means of a pushoff ramp, or off a vertical wall along one side. Figure 3 is a schematic of a picket-dam facility loaded in this manner. Experience has shown that manure can build up in front of a pushoff ramp during freezing conditions. The capability to load the facility along one entire side rather than at a single point (pushoff ramp) reduces such problems. If significant amounts of runoff water are likely to enter the unit, the approach should be shaped with a slight dip to intercept runoff water and direct it around the facility, as shown in Figure 3. Manure can still be pushed up the slight incline to the pushoff area. Picket-dam facilities also can be loaded with mechanical devices designed to handle semisolid manure, such as large piston pumps or conveyor-type barn cleaners. - Picket dam location

The location of the picket dam within the storage facility is important. It should be located at the position farthest away from the loading point, or in the section that manure reaches last as the storage fills up. This allows the natural slope of the manure surface to shed water toward the picket dam. The picket dam also should be at the place from which manure is first removed from the facility during load out. Thus, the dam should be adjacent to or extending up the entry ramp used for load out. Removing manure from the picket-dam area first prevents the formation of pockets that may collect rainwater. - Storage structure

Concrete is the preferred construction material for picket-dam storages. Advantages of concrete include durability, all-weather use, and the ability to form loading or pushoff walls, bucking walls and an impermeable barrier. Picket dams have been successfully used in earthen-walled structures, but cleanout is more difficult because of the sloping earth walls. It is more difficult to structurally integrate the picket dam itself into the earthen walls. An earthen-walled picket-dam structure must have a concrete entry ramp and concrete bottom to avoid scouring as manure is removed.

The concrete entry ramp into the storage should have a maximum 10:1 slope, as shown in Figure 4, and 15:1 is preferred for ease of entry and exit. Some producers prefer having the entry ramp wide enough (40 feet) to park a manure spreader on the ramp while it is being loaded. The entry ramp should be roughened to aid traction during unloading operations. Small channels (3/4-inch by 3/4-inch, 6-inch on-center) cut into the concrete before it sets up will improve traction and drain water toward the picket dam, if they are cut at an angle to slope downhill toward the picket dam. The entry ramp and concrete floor should be placed on a gravel base or compacted fill to prevent settling. The concrete should have at least 3,500 psi compressive strength, and be a minimum of 5 inches thick to support the full spreader and tractor loads which will be imposed. Consider using steel reinforcing to prevent separation due to cracking. Place number 4 (1/2-inch diameter) bars 18 inches on-center, both ways, supported so that they will be in the center of the poured slab (Figure 4). The floor of the structure should be flat, with very little or no slope toward the picket dam. Slope toward the picket dam may cause undesirable manure flow in that direction.

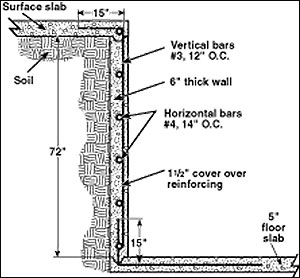

Concrete walls in a manure-storage facility must be designed with adequate strength and reinforcing to withstand loads due to saturated soil outside the wall, pressure of manure inside the wall and any mechanical forces, such as a front end loader pushing manure against the wall. Detailed wall design requires an analysis of the loads that will be present, and selection of adequate concrete and reinforcing to withstand the loads. All potential wall heights and loading conditions cannot be evaluated in this guide. However, Figure 5 shows a design for free-standing walls up to 6 feet in height (the top of the wall is not restrained or tied into another slab). If the top of the wall is tied into another slab, as might be the case on the side where manure is pushed over the wall into the facility, the wall design shown in Figure 6 is adequate.

Figure 6

Figure 6

Design for a concrete wall tied into another slab.

Figure 7

Figure 7

Typical construction details of a picket dam.

Figure 8

Figure 8

Reinforcement for posts in a concrete floor.

Picket dam design

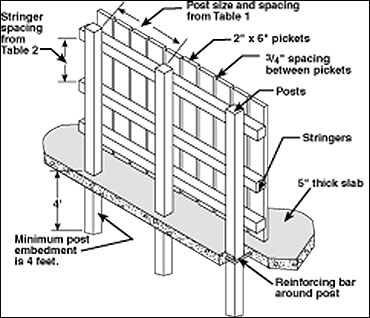

The picket dam must be constructed to withstand the pressure of manure in the facility when it is full. Figure 7 shows typical construction details for a picket dam. The primary structural supports for the picket dam are treated wood posts set a minimum of 4 feet in the ground. Post size and spacing is adjusted according to wall height. Table 1 gives details on post selection and spacing for picket dams. Figure 8 shows a method of reinforcement for the posts in the concrete floor.

Table 1

Post size and spacing for picket dams.

- Wall height = 0 to 4 feet

Post size = 4 inches x 6 inches

Spacing = 5 feet - Wall height = 5 feet

Post size = 6 inches x 6 inches

Spacing = 4 feet - Wall height = 6 feet

Post size = 6 inches x 8 inches

Spacing = 4 feet - Wall height = 7 feet

Post size 8 inches x 8 inches

Spacing 3 feet

Table 2

Spacing for horizontal stringers in picket dams.

- Depth = 0 to 4 feet

Size = 4 inches x 4 inches

Spacing = 36 inches - Depth = 4 to 6 feet

Size 4 = inches x 4 inches

Spacing = 24 inches - Depth = 6 to 8 feet

Size = 4 inches x 4 inches

Spacing = 18 inches

Note

Depth below maximum manure level (top of wall).Note: Lowest stringer should be within 10 inches of floor. Stringers can be fastened to posts with 1/2-inch galvanized bolts.

Horizontal 4- by 4-inch treated wood stringers are attached to the posts at appropriate spacings, according to the height of the picket dam. These supports are closer together near the bottom of the wall where fluid pressures are highest, and farther apart near the top. Table 2 gives proper spacings for horizontal supports, or stringers.

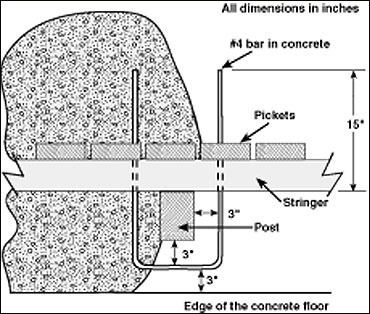

Vertical 2- by 6-inch treated wood pickets are attached to the horizontal treated wood stringers (Figure 9). Three-fourths-inch openings between the pickets allow water to drain through the dam. A 1-1/2-inch deep groove can be cast in the concrete floor as a receptacle for the bottom edge of the pickets, if desired. This will support the bottom edge of the pickets and minimize damage from accidental contact with the loader bucket.

Figure 9

Figure 9

This picket dam drains through 3/4-inch openings between vertical 2-inch x 6-inch treated wood pickets.

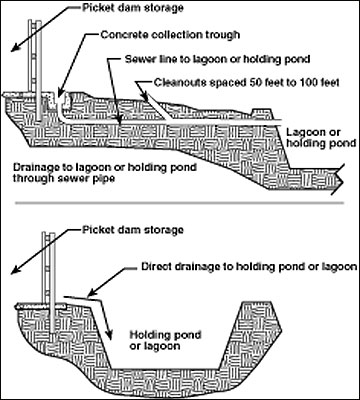

Drainage from the picket dam must be contained or managed so that there is no pollution. The drainage is usually collected in a holding pond, or lagoon, or discharged onto a properly sized vegetated grass filter strip (Figure 10). Figure 11 shows how drainage from a picket dam may flow directly into a holding pond, or how a collection trough and pipe can be used to route the drainage to a pond located further away. If a pipe or sewer line is used to carry the drainage to a holding pond, it should have cleanouts installed every 50 feet to 100 feet to aid in solving plugging problems.

If the picket-dam storage is too low to allow gravity drainage to the holding pond, a collection sump and pump may be used. However, this situation should be avoided, if at all possible, because of the expense and maintenance necessary to install and operate a reliable pumping system.

Figure 10

Figure 10

This picket dam drains directly into a holding pond below the storage structure.

Figure 11

Figure 11

Drainage from a picket dam may flow directly into a holding pond (bottom view), or a collection trough and pipe (top view) may route drainage to a pond located farther away.

Management of a picket-dam storage

Picket-dam storages are usually loaded with manure daily as part of the regular cleanup chores. Manure containing a small amount of bedding works best in picket dams. Manure should be pushed into the storage at the point or side furthest from the picket dam. Care should be taken to minimize the amount of "free" water (usually from lot runoff in a beef operation) entering the storage.

Drainage from the picket-dam storage is highly polluted, and cannot be allowed to enter a stream or watercourse, or discharge from the property. Therefore, the drainage should be collected in a holding pond or lagoon, or applied to a suitable grass filter strip. A lagoon or holding pond used to collect lot runoff may also be used to receive drainage from the picket dam.

Manure removal from picket-dam storages is usually accomplished with conventional manure spreaders and front-end or skid-steer loaders. Some fine solids tend to accumulate immediately behind the pickets, and should be removed when the facility is cleaned. The gaps between the pickets tend to become plugged by manure pressure and cleaning operations. These vertical slots should be cleaned, if necessary, after the facility is emptied so that good drainage can occur.

Haul and land-apply manure to correspond with the growing season of the crop, when possible. Follow best management practices in matching manure nutrients to the fertilizer needs of the crop. Soil tests and manure nutrient analyses aid in determining proper manure application rates. Consider wind direction and location of neighbors when spreading manure but odor problems may occur if the manure is not incorporated as soon as possible. Try not to spread on humid, still days when manure odors can carry longer distances without being diluted.

Under the Unified National Strategy for Animal Feeding Operations, the desired outcome is for all concentrated animal feeding operations (AFOs) to develop and implement a comprehensive nutrient management plan (CNMP). CNMPs should address, as necessary, feed management, manure handling and storage, land application of manure, land management, record keeping, and other utilization options. In addition to nutrients, the plan should address other pollutants, such as pathogens, to minimize water quality and public health impacts from AFOs.

At a minimum, the nutrient management plan should prevent the application of nutrients at rates that exceed the capacity of the soil and planned crop needs and should also prevent pollution. Soils, crop removal and manure should be tested to determine nutrient needs and content. Manure application equipment should be calibrated to ensure that the quantity of material being applied is what is planned. Records of crops removed annually and the total amount of manure applied should be kept to maintain the desired nutrient balance.

Sizing a picket-dam storage

The size of a picket-dam storage facility depends upon the size and number of animals served, the ration, the portion of total manure production scraped into the storage and the length of time or storage period between cleanouts. Minimum design storage period should range from 90 days in southern Missouri to 120 days in northern Missouri if the land application area is in a permanent cover crop, such as fescue or brome grass. However, if the land application area is in row crops, 365-day storage may be required for maximum utilization of the nutrients and for application to correspond with planting and harvesting schedules. Table 3 PDF lists the estimated daily manure production for various types of cattle and feeding regimes. Table 4 PDFgives the fraction of total manure production expected in the various parts of the facility. Add half for the volume of bedding added to the picket dam storage.

Further information

- Bruns, E.G., and J.W. Crowley. 1972. Solid Manure Handling for Livestock Housing, Feeding and Yard Facilities in Wisconsin (A2418). University of Wisconsin Extension, Madison, Wisconsin.

- NRAES31, Dairy Manure Management

- USDA-Natural Resources Conservation Service. 1992. Agricultural Waste Management Field Handbook, Part 651. USDA-NRCS, Washington, D.C.