Poultry litter is a mixture of poultry manure and the sawdust or rice hull bedding from confinement buildings used for raising broilers, turkeys and other birds. Poultry growers must periodically clean their buildings to promote bird health and limit buildup of wet manure. Partial cleaning, known as decaking, occurs after each flock is removed from the building. Litter that has built up, particularly near waterers and feeders, is removed before the new birds are brought into the building. Typically, all litter is removed from the building annually and replaced with fresh bedding.

This byproduct of the poultry industry can be an excellent fertilizer for crops. It contains nitrogen, phosphate, potash, and micronutrients essential for crop growth (Table 1). Table 2 summarizes the fertilizer content of selected types of poultry litter.

Table 1

Mean nutrient content of broiler litter.

| Nutrient | Pounds per wet ton |

|---|---|

| Total nitrogen | 69 |

| Ammonia nitrogen (NH4-N) | 16 |

| Nitrate nitrogen (NO3-N) | 0.1 |

| Phosphate (P2O5) | 82 |

| Potash (K2O) | 38 |

| Calcium (Ca) | 38 |

| Magnesium (Mg) | 16 |

| Manganese (Mn) | 0.4 |

| Sodium (Na) | 15 |

| Zinc (Zn) | 0.2 |

| Sulfur (S) | 14 |

| Iron (Fe) | 2 |

| Copper (Cu) | 0.1 |

Data are based on poultry litter from nine Missouri broiler houses sampled after three to six flocks. All values are on a pounds per wet ton (as-is) basis.

Table 2

Estimated range of nutrient concentration in selected types of poultry litter (pounds per wet ton).

| Litter type | Total N | Ammonia N | Phosphate | Potash |

|---|---|---|---|---|

| Broiler | 45 to 75 | 8 to 20 | 50 to 80 | 35 to 75 |

| Broiler cake | 40 to 60 | 5 to 15 | 50 to 80 | 45 to 90 |

| Broiler breeder | 20 to 50 | 5 to 15 | 40 to 70 | 15 to 55 |

| Turkey | 50 to 80 | 8 to 20 | 45 to 105 | 25 to 65 |

All values are reported on a pounds per wet ton (as-is) basis.

Book values provide an estimate of the nutrient value of poultry litter for planning purposes. However, there can be a wide range of nutrient concentration among poultry houses. Nutrient concentrations in one house can be half or double that in another house under different management. Factors affecting nutrient content of the poultry litter include bird type, feed composition and efficiency, and building management factors such as cleanout frequency, type of waterer and management, decaking management, and the use of litter additives such as alum. The unpredictability of nutrient content from house to house makes nutrient testing of manure an essential part of using poultry litter as a fertilizer for crop production.

Sampling poultry litter before a full cleanout

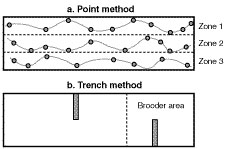

Two methods are suitable for sampling poultry litter, the point and the trench methods. The trench method may be difficult with birds in the building because feeders and water lines may complicate digging the trench and maneuvering the wheelbarrow.

The objective of both methods is to obtain a representative sample of the nutrient content of the litter in the house. It may take more than 30 minutes to sample a building properly. This may seem like an excessive amount of time, but the proper procedure is necessary to obtain usable results.

Point method

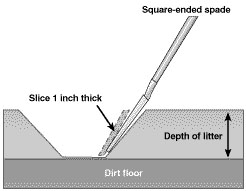

The point method requires a 5-gallon bucket, a narrow, square-ended spade and a 1-quart plastic freezer bag. A soil probe can be used instead of the spade.

Visually divide the house in to three zones. If the house runs in the east-west direction, then divide the house into northern, middle, and southern thirds (Figure 1a). Walk the length of the building in one zone in a zigzag pattern taking a subsample with the spade at 8-10 random points along your path (10-12 points if you are using a soil probe). Be sure to take cores (a representative number) under feeders and waterers. At each sampling point, clear a small trench the width of the spade to the depth of the litter. Then remove a 1-inch slice, being sure to get equal amounts of litter from all depths (Figure 2). If you are using a probe, insert the probe the entire depth of the litter, avoiding the dirt floor below. Obtaining a quality sample with a soil probe can be difficult in dry litter. Repeat the process in each of the three zones, putting all samples into the bucket.

Figure 1

Figure 1

Sampling patterns for the point and trench methods.

Figure 2

Figure 2

Using the point method with a square-ended spade, first dig a small trench before removing the sample. This ensures that equal amounts of litter are removed from all depths.

After collecting samples from all three zones, crumble and thoroughly mix all the litter in the bucket. With the larger amount of material collected with the spade, it may be easier to pour the material onto a piece of plastic, plywood or into a wheelbarrow to facilitate mixing. After thoroughly mixing the sample fill the freezer bag with a subsample. Label the sample with the operation name, building name and date of sampling.

Trench method

The trench method requires a square-ended spade, a wheelbarrow, a 5-gallon bucket and a 1-quart freezer bag. At approximately the middle of the brooder portion of the building, dig a trench from the midline of the building to the sidewall (Figure 1b). The square-sided trench should be the width of the spade and extend down to just above the dirt floor (Figure 3). Place all material removed from the trench into the wheelbarrow. Repeat the process at one other point in the building as shown in Figure 1b.

Figure 3

Figure 3

The trench method. Use the blade of the shovel to chop the cake so the trench has square sides down to just above the soil surface.

After collecting the sample, crumble and thoroughly mix all the litter from the two trenches in the wheelbarrow with the spade (Figure 4). After thoroughly mixing the sample, fill the freezer bag with a subsample. Label the sample with the operation name, building name and date of sampling.

Figure 4

Figure 4

Be sure to crumble chunks of caked litter into small pieces and thoroughly mix the litter before removing your sample.

Often the amount of material collected from the two trenches will exceed the capacity of the wheelbarrow. When this happens, crumble and thoroughly mix the material in the wheelbarrow each time it is two-thirds full with material from the trenches. After mixing, place one shovelful in the 5-gallon bucket, empty the remainder of the litter from wheelbarrow to the side of the trench and repeat the process until you have completed both trenches. Then thoroughly mix the material collected in the bucket and fill the freezer bag with a subsample from the bucket.

Sampling cake litter

Use the same sampling methods for cake litter as for sampling before a full cleanout, but remove litter only to the depth of the cake. Alternatively, follow the procedure below for sampling litter during cleanout.

Sampling litter during cleanout

This method requires a shovel, a wheelbarrow and a 1-quart freezer bag. Take a shovelful of litter from each truckload and put it in the wheelbarrow. After collecting litter from all truckloads from a barn, thoroughly mix the litter in the wheelbarrow. Fill the freezer bag with a subsample and label it with the operation name, building name and date of sampling. Alternatively, use the trench or core method immediately before cleaning the building.

Sampling litter piles

Collecting a representative sample from a litter pile requires a shovel, a 5-gallon bucket and a 1-quart freezer bag. From each of 10 to 12 widely dispersed points on the pile, remove 2 to 5 shovelfuls of litter and set it aside. Mix this litter and place one shovelful in the bucket.

After collecting samples from all points, crumble and thoroughly mix all the litter in the bucket. Fill the freezer bag with a subsample, and label it with the operation name, building name and date of sampling.

The key to sampling litter piles in composting or other storage facilities is to obtain multiple samples throughout the stack at a time the nutrient content of the stack is relatively stable. Do not sample a freshly stacked or turned pile unless you plan to spread litter from the pile within the next day or two. Nutrient content should stabilize about two weeks after forming a new pile or turning an existing pile.

Handling and timing of poultry litter samples

Manure samples should be sent to the testing lab the same day they are collected. If you hold the sample longer than 24 hours, freeze the sample until it is sent to the testing lab. Do not let your samples sit in a hot spot such as the dashboard of a vehicle. It is best to send samples early in the week so that they do not sit in the mail over the weekend.

At a minimum, request the following laboratory tests for each sample:

- Total nitrogen (N) or total Kjeldahl N (TKN)

- Ammonium or ammonia N

- Total phosphorus

- Total potassium

- Percent moisture or percent dry matter

Not all testing labs report ammonia N. Ammonia N typically makes up 15 to 25 percent of the total N in a sample; dry litter has lower ammonia N concentrations than other manure types. If the lab does not report this value, assume 20 percent of the total nitrogen is ammonia N.

Ideally, poultry litter should be sampled before cleaning so that sample results are available when the litter is spread. Samples taken too early will underrepresent the nutrient content of the litter; results of samples taken too late will not be available to guide land application of manure. Alternatively, samples can be taken at the time of cleanout, and historic values can be used for land application. Calculation of the actual fertilizer value of the applied litter can be made when the manure test results are returned.

Interpreting poultry litter test results

The first step in interpreting a manure test is to check the units used to report the results. Poultry litter is typically applied on a pounds of nutrient per wet ton (as-is) basis. Manure test results may be reported as percent nutrient ( percent) or parts per million (ppm) or, on rare occasions, on a dry weight basis. The phosphorus and potassium may be reported on an elemental basis (P and K) rather than the phosphate (P2O5) and potash (K2O) basis typical of fertilizers. See the box below to convert your manure test results into the proper fertilizer units.

Adjusting units of measure in manure test results

Conversion factors

- Pounds per ton = percent x 20

- Pounds per ton = ppm x 0.002

- Nutrient level wet basis = nutrient level dry basis x (100 - percent moisture) ÷ 100

- Phosphate = elemental phosphorus (P) x 2.27

- Potash = elemental potassium (K) x 1.2

Example

A laboratory test of a poultry litter sample yields the following values (on a wet or as-is basis).

- Moisture, percent: 26.8

- Total nitrogen, percent: 3.2

- Ammonia nitrogen, percent: 0.5

- Phosphorus, percent: 1.5

- Potassium, percent: 2.1

The nutrient results need to be converted from percent to pounds per wet ton basis, and phosphorus and potassium need to be converted to phosphate and potash fertilizer basis.

- Total nitrogen = 3.2 percent x 20 = 64 pounds per ton

- Ammonia nitrogen = 0.5 percent x 20 = 10 pounds per ton

- Phosphate = 1.5 percent x 20 x 2.27 = 68 pounds per ton

- Potash = 2.1 percent x 20 x 1.2 = 50 pounds per ton

Poultry litter is an excellent fertilizer if care is taken to spread the litter uniformly on a field. A pound of manure phosphate or potash has a nutrient value equivalent to that of commercial fertilizer. Poultry litter also has value as a nitrogen fertilizer, but only a portion of the nitrogen is available to crops. Typically, 70 percent of the total nitrogen applied is available to the crop.

Poultry litter is an unbalanced fertilizer; repeated applications based on the nitrogen need of pasture, hay or row crops will lead to a rapid buildup of soil test P and K levels in the soil. Poultry litter typically has nearly equal concentrations of nitrogen and phosphate. This is beneficial on soils testing low in P, but excessive buildup can occur if manure is applied based on crop nitrogen need year after year. Excessively high soil test P can result in reduced water quality in lakes and streams. Apply manure to fields that have the greatest need for phosphate and potash.

Calibrate your manure spreader

Effective management of poultry litter as a fertilizer requires periodically checking the capacity of your spreader. The quantity (weight) of litter applied per load will change as the moisture content and litter type varies. Determine the capacity of your spreader by weighing it both full and empty.