The most important aspect of the location of your liquid-petroleum storage tank is how close it is to your drinking-water well. State water well-driller regulations outlined in the Water Well Drillers Act of the Missouri Revised Statutes (RSMo 256.600) require petroleum storage tanks be located at least 300 feet from a drinking-water well. Minimum separation distances regulate only new-well installation. Existing wells are required to meet only separation requirements in effect at the time of well construction. Make every effort, however, to exceed old regulations and strive to meet current regulations whenever possible.

Although diesel fuel and fuel oil are more dense than gasoline and move more slowly through the soil, they eventually will reach groundwater.

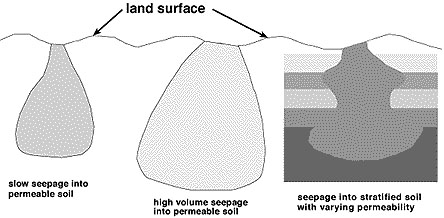

Every site has unique geologic and hydrologic conditions that can affect groundwater movement. How quickly the petroleum product reaches groundwater also depends upon local soils. The more porous the soil — sands and gravels, for example — the faster the rate of downward movement to groundwater. You may put a new tank more than 300 feet away from your well to provide reasonable assurance that subsurface flow or seepage of contaminated groundwater will not reach your well. If possible, you should place the tank downslope from the well. Figure 1 illustrates petroleum product seepage into soils.

If you have an above-ground tank, follow existing regulations for underground storage tanks as a guide. To protect against explosion and fire, do not put tanks (especially above-ground tanks) closer than 50 feet to existing buildings. Previous regulations for placing above-ground storage tanks were concerned more with the explosion potential of tanks than the groundwater pollution potential. State agencies have revised above-ground storage-tank regulations to better protect groundwater.

Figure 1

Figure 1

Petroleum product seepage into soils. Source: Underground Tank Corrective Action Technologies, EPA/625/6-87-015, January 1987.

New storage-tank location

Along with maintaining adequate distance from your drinking-water well, choose a location for a new tank based on the following considerations:

- Soil characteristics

Highly corrosive clays, wet soils, cinders and acid (low pH) soils can significantly speed up the rate of corrosion of underground metal tanks and piping. Using clean backfill during installation can decrease the negative effects of surrounding soils. - Soil stability

Assess the ability of underlying soil to support both underground and above-ground tanks. For special tank locations, such as hillsides, properly anchor and hold tanks in place. Be sure pipes cannot twist or break if the tank is bumped or disturbed. Regardless of soil conditions, put above-ground tanks over an impermeable liner made of concrete or one of the newer synthetic fabrics. Build a collection device for spills. - Current and previous land use

Sites that contain abandoned pipes and tanks, agricultural drainage tiles or waste materials pose special installation problems. Any metal already in the ground at your chosen site will increase corrosion rates for the new tank. - Traffic

Assess traffic patterns around the tank. Determine if the location of the tank or dispenser will block movement of farm vehicles during refueling or cause special problems if any work needs to be done on the tank. Protect piping from collisions with farm and fuel vehicles. - Depth to groundwater

Floodways or areas where the water table is close to the surface are poor locations for storage tanks. Tanks placed in such areas require special installation. To reduce pollution potential, you may prefer an above-ground tank to an underground tank.

Tank design and installation

Whenever you install a fuel-storage tank, carefully follow the manufacturer's recommended practices for installation. Proper installation is one sure way to minimize leakage potential of the tank or the piping connected to it. Even scratches in a metal tank caused by careless installation can increase corrosion and tank deterioration.

Underground tanks

All new underground petroleum storage tanks and related piping must be constructed of nonmetallic materials such as fiberglass or have corrosion protection. Corrosion protection includes interior liners and sacrificial anodes.

A sacrificial anode is a special material connected to the tank with a greater tendency to corrode than the tank material. The anode will typically protect the tank for up to 30 years. Interior liners are made of noncorrosive synthetic materials and also can be effective in protecting metal tanks.

All new underground storage tanks should have some kind of spill protection. This typically consists of a catch basin for collecting spills when the tank is filled. Overfill protection warns of or prevents overfill with an automatic shut-off or buzzer. Spill and overfill protection are important; they can prevent a number of small releases over a long period of time from polluting the groundwater.

Above-ground tanks

State regulations for above-ground tank installation seek to reduce the potential for both pollution and fire. Requirements include enclosing the tank within a secure 6-foot fence or well-ventilated building of noncombustible material and constructing a fire wall between the fuel-dispensing area and the tank.

To decrease pollution potential, place farm tanks within a secondary containment structure consisting of a dike and a pad. All piping should be above ground within the dike or may go over the dike wall, but below-ground piping must be within 10 feet of the dike wall. Above-ground piping must be made of steel and coated to prohibit corrosion. Below-ground piping may be either steel or fiberglass. Steel tanks must be coated and cathodically protected.

Monitoring

Regulations for new underground tanks require that all tanks have a method of detecting leaks. Select the tank location carefully to ensure ease of installation and reliability of chosen leak-detection methods. Test the tank periodically for leaks, and measure the tank inventory on a monthly or more frequent basis to detect leaks before major problems develop.

Because cleanup of gasoline leaks is always costly and often not totally effective, it is important to constantly monitor underground tanks containing petroleum products.

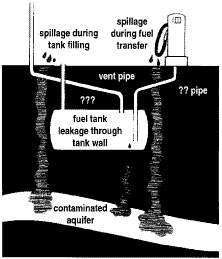

If you already have a petroleum storage tank on your farm, know the age of your tank and establish a leak-detection program. Figure 2 shows how groundwater can be contaminated by underground tanks.

Because most tanks used on farmsteads are bare steel, tank corrosion or piping problems will cause leaks sooner or later. If your tank is more than 20 years old, or if you don't know its age, make a special effort immediately to determine whether leaks exist.

You can test tank integrity through such methods as precision testing/tightness testing and volumetric analysis. State regulations prohibit some other testing methods. Air-pressure testing, for example, is prohibited if a tank has ever contained product.

Ask for a list of approved tank-testing methods and suppliers' phone numbers from the Missouri Department of Natural Resources (DNR) Hazardous Waste Program at 573-751-3176.

Even when a tank has been tested and proven tight, existing regulations and good practice require that you have a method for regularly detecting leaks.

Install such internal or external monitoring methods as groundwater monitoring wells, vapor monitoring, automatic tank gauging or other approved methods.

Measuring tank inventories is an inexpensive and easy way to help detect leaks. Leaks exist when there is any decrease in level over time without any withdrawal of fuel, or if there's an increase in water in the tank. Although inventory measurement will not detect small leaks, it will provide a warning that further investigation may be necessary.

If you use a measuring stick to measure tank liquid level, be sure that the stick does not puncture or damage the bottom of the tank.

The closer the tank is to the farmstead's drinking-water well, the more important it is to ensure that an adequate leak-detection system is in place.

The DNR, Division of Environmental Quality, administers the Petroleum Underground Storage Tank Insurance Fund, which can reimburse participating tank owners for a substantial percentage of costs incurred in cleaning up a problem for federally regulated tanks or home-heating fuel tanks. For more information about the fund, call the DNR at 1-800-765-2765. Residential and farm vehicle-fuel tanks with less than 1,100-gallon capacity are not federally regulated and therefore are not eligible for this assistance.

Figure 2

Figure 2

Contamination of groundwater due to improper fuel storage and transfer. Source: Handling and Underground Storage of Fuels, Cooperative Extension Service, Michigan State University, Extension Publication WQ1. Reviewed February 1986.

Tank closure

Tanks no longer in use can cause problems for owners and operators many years later. They will continue to corrode and, if they still contain gas or oil, will likely contaminate groundwater.

Try to find unused tanks on your property. Also, try to find out whether the tanks still hold product or have holes. You must pull these tanks from the ground and dispose of them in a landfill or at a scrap dealer.

State law requires that certified individuals pull a tank. Before pulling a tank, always notify your local fire department at least one month before you have the tank pulled to ensure that precautions are taken to prevent an explosion or other problem. Deaths have occurred because of improper closure.

If you are concerned that your unused tank has been leaking, consult an environmental engineer or DNR investigator to determine if further investigation is warranted. If there is groundwater pollution in your area, your neighbors will be sure to suspect the tank as its cause. The DNR also has regulatory authority to investigate potential pollution situations and recover costs from responsible parties.

You should document steps you take to legally close your tank — including notifying the DNR, Division of Environmental Quality, that the tank has been closed — so that you are protected from legal action in the event of groundwater problems.

Resources

- Revised Missouri Statutes, Water Well Drillers Act (RSMo 256.600) are available online

- For information about tank registration, reporting closure and changes in tank ownership, contact the Missouri Department of Natural Resources, Hazardous Waste Program, 573-751-3176.

- For information about U.S. Environmental Protection Agency (EPA) regulations, contact the Region VII Air and Waste Management Division, 913-551-7494.

- For information on petroleum product spills, contact your local MU Extension office, or a regional DNR office listed below:

- Kansas City

816-251-0700 - Northeast (Macon)

660-385-8000 - Southeast (Poplar Bluff)

573-840-9750 - Southwest (Springfield)

417-891-4300 - St. Louis

314-416-2960

- Kansas City

- For information about the health effects of gasoline-contaminated groundwater, contact the Missouri Department of Health and Senior Services, Bureau of Environmental Epidemiology, 866-628-9891 or 573-751-6102.

Farm•A•Syst: Farmstead Assessment System Fact Sheet: This guide, previously named MU publication WQ678 Reducing the Risk of Groundwater Contamination by Improving Petroleum Product Storage, was originally produced as part of the Missouri Farmstead Assessment System — a cooperative project of MU Extension; MU College of Agriculture, Food and Natural Resources; and the Natural Resources Conservation Service — and was adapted from Wisconsin and Minnesota prototype versions of Farm•A•Syst.