Biosolids are organic materials resulting from the treatment of wastes primarily coming from municipal and residential sources. Biosolids typically contain minerals and organic matter that can be beneficial to the soil and crop environment, and to the general tilth of the soil. See MU publications WQ428 and WQ430 for detailed information on nutrient content and agronomic considerations for applying biosolids to crops. This publication discusses the collection and storage of biosolids at the treatment plant for subsequent land application.

Biosolids characteristics

The physical characteristics of biosolids influence the type of handling equipment needed. Most biosolids resulting from the treatment of municipal sewage have a dry matter content of 3 percent to 6 percent. This type of biosolids is a somewhat viscous fluid (similar to a chocolate malt) and can be handled hydraulically by pumps, pipelines and applicators designed for this type of material.

Biosolids that are further dewatered by filter or press may contain up to 30 percent dry matter. This type of biosolids is handled by mechanical loading, hauling and spreading equipment. The obvious advantage of the drier biosolids is the significant reduction in water volume, which in turn reduces handling costs. However, due to the relatively high cost of reducing moisture, most biosolids are handled as a fluid.

Collection and storage at the treatment plant

The treatment and stabilization of municipal sewage continuously produces biosolids. Appropriately designed pumps and piping systems are typically used to collect and transfer biosolids at the treatment plant. Since biosolids cannot be land-applied year-round, some storage is necessary to accumulate the material during times when it cannot be spread. The size of a biosolids storage structure depends upon the rate of biosolids production and the length of storage period needed. Up to one year's storage is desirable for the flexibility needed in a land application program for biosolids.

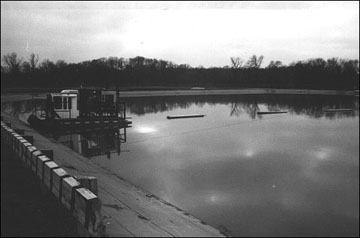

Lagoons are a common type of storage structure for biosolids (Figure 1). Generally, long-term storage of biosolids can be obtained at a lower cost in a lagoon as compared to other types of structures. Lagoons used for biosolids storage should be constructed with a liner that will not erode as the contained biosolids are removed.

Figure 1

Figure 1

Lagoons can provide long-term storage of biosolids; a dredge uses a winch and cable to travel over the lagoon surface.

Since biosolids tend to settle and accumulate at the bottom of a storage structure, some type of mechanical equipment is usually necessary to remove them. Figure 2 shows a dredge-type biosolids removal device typically used on lagoons. These dredges are usually equipped with a horizontal auger that can be lowered to a specific depth in the lagoon (Figure 3). The auger moves the biosolids to the self-contained pump, which in turn pumps the biosolids from the lagoon to the next point in the system. These dredging devices typically contain their own internal combustion power unit, and may be operated either remotely or by an on-board operator. Movement of the dredge over the lagoon surface is controlled by a cable-and-winch arrangement allowing biosolids to be removed from the entire lagoon bottom as the dredge travels over the surface (Figure 1).

Biosolids removed from long-term storage, such as a lagoon, may be accumulated in a short-term storage tank (sometimes referred to as a day tank) to await the next step in the land-application process. Figure 4 is an example of such a surge-storage tank from which the biosolids can be pumped in the next land-application step.

Figure 2

Figure 2

The dredge used for removal of biosolids from a lagoon.

Figure 3

Figure 3

The horizontal auger on this dredge can be lowered to the bottom of the lagoon for biosolids removal.

Figure 4

Figure 4

Short-term storage tank for biosolids removed from a lagoon.

Short-term storage of biosolids in steel or concrete tanks is commonly used by smaller municipalities in lieu of a lagoon. Such short-term storage is manageable if grassland spreading sites are available and can be accessed throughout the year. However, a minimum of 60 days to 90 days storage is recommended for south Missouri and 90 days to 120 days for central and north Missouri.

References

- City of Columbia, Columbia Wastewater Treatment Plant, Sludge Management Program.

- Robinson, John. Operations Supervisor, City of Columbia, Wastewater Treatment Plant, P.O. Box N, Columbia, Mo. 65205, 573-445-9427. Personal communication, 1993.

- Missouri Department of Natural Resources, Division of Environmental Quality. Agricultural Use of Municipal Wastewater Sludge — a planning guide. January 1985.

- Biosolids "Train the Trainer" Workshop. Course notebook. MU Extension. January 20-21, 1994.

Previous title

WQ431, Collection and Storage of Biosolids

Original author

Charles Fulhage