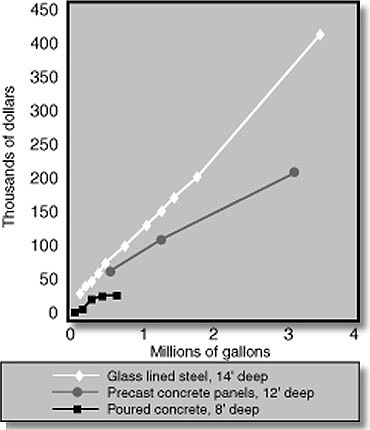

Storage structures for liquid livestock manure range from low-cost earthen basins and moderate-cost concrete tanks to higher-cost, glass-lined steel tanks. Figure 1 shows a cost comparison for some typical structures. Due to the high cost of storage volume, tanks are not usually used to contain large volumes of lot runoff. It is important to minimize the runoff area draining into the tank to increase ease of management and reduce tank size. Tanks offer an alternative for waste storage in areas with karst terrain, where the site is rated as having a severe collapse potential and an earthen pit will not be approved. This publication deals with concrete and steel tanks but not with concrete pits under buildings.

Tanks may be located above grade, below, or partially below grade. Below-grade tanks are easy to fill by scraping, whereas above-grade tanks may require pumps for filling. Open storage structures should be located to minimize odor and sight nuisances, but they should be located as convenient to the source of waste as practical. Tanks should be located at least 300 feet from water wells. Open tanks should be fenced, as necessary, to exclude animals and children. Tanks filled by scraping should have guardrails or grates to prevent machinery as well as animals and people from entering the tank.

Figure 1

Figure 1

Comparative costs for various manure storage structures.

Tank design — size

Manure tanks are sized by volume. Proper design, or sizing, of a tank ensures that sufficient volume is available for the required storage period. In the past, the Missouri Department of Natural Resources has accepted storage periods of 90 days for southern Missouri to 120 days for northern Missouri. Longer storage periods offer greater flexibility in scheduling pumping operations and making use of manure nutrients. MU Extension agricultural engineering specialists and Natural Resources Conservation Service engineers have a computer program to expedite tank (and lagoon) sizing and design. The total volume (size) of a tank is composed of several volume fractions:

- Residual volume

This fraction of the tank volume consists of a 6- to 12-inch depth at the bottom of the tank that normally cannot be pumped out if the tank has no sump. - Manure storage volume

This fraction of the tank volume provides storage for the volume of manure the tank will receive during the design storage period, and is removed when the tank is pumped. - Wash water volume and other sources

This fraction of the tank volume provides storage for any wash water or other fresh water used for cleaning buildings or lot areas and any other volumes, such as waterer spillage/leakage. - Net rainfall/evaporation on the tank surface

This fraction of the tank volume provides storage for the net gain of rainfall over evaporation on the surface of open-top tanks. Volume components affected by rainfall (rainfall/evaporation volume and runoff volume) must be determined based on the wettest year in 10 years for approval by the Missouri Department of Natural Resources (DNR). For the wettest year in 10, the rainfall minus evaporation varies from about 1 foot per year in northwest Missouri to 3 feet per year in southeast Missouri. - Runoff

Runoff from roofs and concrete lots for the wettest year in 10 ranges from about 3 feet per year in northwest Missouri to 4.5 feet per year in southeast Missouri. - Freeboard

Pumping operations should be initiated before the tank is full to ensure that space (freeboard) is always available to hold the 25-year, 24-hour storm (6 inches in Missouri). DNR guidelines call for pumping the tank when the water level is 1 foot or more below the full pool level, if minimal open lot area contributes input to the tank. This allows for the recommended 6 inches of freeboard if a 6-inch storm (25-year, 24-hour storm) occurs when the liquid level is one foot below the top of the tank.

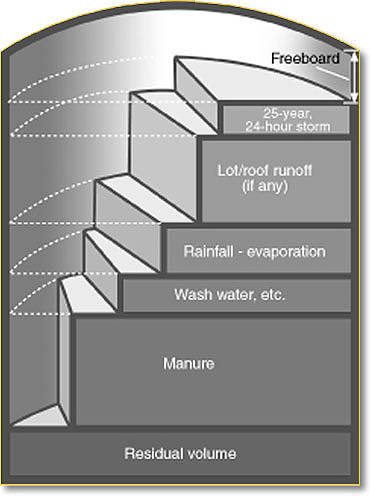

Figure 2

Figure 2

Schematic of volume fractions in manure tank design.

Figure 2 shows the volume fractions considered in the design of liquid manure tanks in Missouri. It is recommended that pumping of the tank begin when the level reaches the bottom of the 25-year, 24-hour storm volume segment shown in Figure 2. This ensures that 6 inches of freeboard and volume for the 25-year, 24-storm is always available. When there is no lot runoff, the "begin pumping" level will be 1 foot below the top edge of the tank (6 inches freeboard plus 6 inches for the 25-year, 24-hour storm). If significant lot runoff enters the tank, the "begin pumping" level will be more than 1 foot below the top edge of the tank.

Table 1 shows typical tank sizes for various sizes of livestock operations in Missouri. These values are averages only and should not be used in lieu of a specific design.

Table 1

Typical sizes of open-top manure storage tanks with 365-day storage capacity in an area of central Missouri with a 40-inch average annual rainfall and no lot runoff (except for beef, see footnote 6).

| Animal type | Number | Manure production and water added per year | Manure production and water added per year | Required diameter for an 8- foot-high tank (includes safety volume) | Required diameter for a 14- foot-high tank (includes safety volume) |

|---|---|---|---|---|---|

| Swine | |||||

| Sow and litter1 | 50 | 13,000 cubic feet | 96,000 gallons | 48 | 34 |

| Sow and litter1 | 100 | 26,000 cubic feet | 191,000 gallons | 68 | 48 |

| Sow and litter1 | 300 | 76,000 cubic feet | 570,000 gallons | 118 | 82 |

| Sows, boars and gilts2 | 200 | 16,000 cubic feet | 121,000 gallons | 54 | 38 |

| Sows, boars and gilts2 | 400 | 32,000 cubic feet | 241,000 gallons | 76 | 53 |

| Sows, boars and gilts2 | 800 | 64,000 cubic feet | 480,000 gallons | 108 | 75 |

| Sows, boars and gilts2 | 1,200 | 96,000 cubic feet | 719,000 gallons | 132 | 92 |

| Nursery pigs3 | 500 | 11,000 cubic feet | 79,000 gallons | 44 | 31 |

| Nursery pigs3 | 1,000 | 21,000 cubic feet | 158,000 gallons | 62 | 43 |

| Nursery pigs3 | 3,000 | 63,000 cubic feet | 471,000 gallons | 107 | 75 |

| Finishing4 | 500 | 39,000 cubic feet | 293,000 gallons | 84 | 59 |

| Finishing4 | 1,000 | 78,000 cubic feet | 584,000 gallons | 119 | 83 |

| Finishing4 | 3,000 | 234,000 cubic feet | 1,747,000 gallons | 206 | 144 |

| Finishing5 | 500 | 30,000 cubic feet | 225,000 gallons | 74 | 52 |

| Finishing5 | 1000 | 60,000 cubic feet | 448,000 gallons | 104 | 73 |

| Finishing5 | 3,000 | 179,000 cubic feet | 1,341,000 gallons | 181 | 126 |

| Beef | |||||

| Feeders at 1,000 pounds6 | 150 | 110,000 cubic feet | 820,0000 gallons | 141 | 99 |

| Feeders at pounds6 | 300 | 219,000 cubic feet | 1,636,000 gallons | 200 | 139 |

| Feeders at 1,000 pounds6 | 600 | 437,000 cubic feet | 3,269,000 gallons | 282 | 197 |

| Dairy cow, 1,400 pounds | |||||

| Lactating7 | 100 | 144,000 cubic feet | 1,081,000 gallons | 162 | 113 |

| Lactating7 | 200 | 289,000 cubic feet | 2,158,000 gallons | 229 | 160 |

| Lactating7 | 300 | 432,000 cubic feet | 3,235,000 gallons | 280 | 196 |

| Lactating7 | 500 | 720,000 cubic feet | 5,388,000 gallons | 362 | 253 |

- Includes wash water estimated to average 1 gallon per crate per day and 450 pounds average weight.

- Includes wash water estimated to average 0.1 gallon per head per day and 375 pounds average weight.

- Includes wash water estimated to average 0.05 gallon per head per day and 25 pounds average weight.

- Dry feeders. Includes wash water estimated to average 0.1 gallon per head per day and 150 pounds average weight.

- Wet/dry feeders. Includes wash water estimated to average 0.1 gallon per head per day and 150 pounds average weight.

- For animals on a high-energy ration, includes runoff from an open concrete lot based on 50 sq feet of lot per animal but no wash or flush water.

- Includes wash water from the milkhouse and parlor estimated to average 4.5 gallons per 1,000 pounds of animal per day.

Notes

The gallons per year includes the rainfall into the tank for the wettest year in 10. Assumes 1-foot safety volume (or more if lot runoff dictates) at top of tank and a sump in the bottom of the tank for complete emptying. (Volume gallons per year does not include the safety volume.)

Tank depths from 8 to 20 feet are typical. Deep tanks offer the following advantages.

- A smaller surface area requiring less space.

- Minimum odors.

- Efficient use of mechanical agitation.

Tank design — structural

The interior hydrostatic wall pressure for structural design is 60 pounds per square foot per foot. Design loads on the exterior of walls consist primarily of lateral earth pressures, surcharge pressures and hydrostatic pressures. Earth pressures vary with backfill soil type and compaction, with equivalent fluid pressures ranging from 30 to 115 pounds per square foot per foot. Where heavy equipment may operate within 5 feet of the wall, the wall should be designed for a minimum additional 100 pounds per square foot surcharge pressure uniformly distributed over the exterior wall height. Exterior hydrostatic pressures vary with the water table level and degree of drainage. Belowground tanks can experience unbalanced uplift forces when the soil outside the tank is saturated. Provide adequate foundation and perimeter drainage around the tank to minimize the possibility of upward movement when the tank is empty. Tank covers must be designed for dead loads, and equipment and livestock loads, if applicable. In selecting a tank configuration, consider agitation and pumpout requirements, and the possible need for partitions or supporting walls within the tank itself.

A professional engineer or other qualified consultant should be engaged to assist in the design of concrete manure storage structures. To be approved by the Missouri Department of Natural Resources (DNR), concrete designs should meet minimum standards of the Midwest Plan Service (MWPS). To be approved for cost-sharing by the EQIP Program, concrete designs should meet minimum standards of the Natural Resources Conservation Service (NRCS). Properly designed precast concrete stave and concrete panel tanks are also acceptable. Structural analysis and designs should conform to relevant codes and engineering standards. Design guidelines for tanks can be found in ASAE EP393.3 of the ASAE Standards.

Concrete tank design should conform to the American Concrete Institute's Building Code for Reinforced Concrete (ACI 318). Inward and outward forces on tank walls, especially on noncircular tanks, require the design of highly reinforced, costly walls. Rectangular tanks are generally limited to 8 to 12 feet depths and unbraced wall lengths of 40 to 50 feet because of structural requirements. To minimize the required wall section for the top of straight concrete walls that have no support for outward or inward deflection, a common practice is to cast a thickened section at the top of the wall or to cast an integral, outward slab to greatly increase the section modulus. A circular configuration is the most efficient structural design, and circular concrete tanks are commonly constructed up to 120 feet in diameter and 20 feet deep. Typical wall heights for poured-in-place, reinforced-concrete tanks range from 8 to 16 feet. On circular concrete-stave tanks, steel hoops are sized or spaced to withstand the higher pressures at the bottom of the wall.

Glass-lined steel tanks

Glass-lined steel tanks are usually purchased from a company that provides a tank designed to withstand the 60 pounds per square foot per foo t hydrostatic load imposed by the contained liquid, and exterior wind loads. Steel tanks should conform to the American Institute of Steel Construction Specifications for the Design, Fabrication, and Erection of Structural Steel for Steel Buildings. Typical steel tank depths range from 10 to 25 feet with diameters up to about 200 feet and volumes up to 4 to 6 million gallons.

Transferring manure to storage

Manure in the slurry form is usually transferred to storage tanks by scraping or by using a pump designed for semisolids. Semisolids may be scraped directly into the tank, usually from a push-off slab, or scraped into a reception pit and pumped into the storage tank.

Reception pits are usually designed with capacity for one day's manure production; a pit 8 feet long, 4 feet wide and 6 feet deep will serve a 100-cow dairy herd.

Reception pits receiving lot runoff must be equipped with automatic pumping units to prevent an overflow of the reception pit during a rainfall event.

Agitation

Figure 3

Figure 3

Circulation with a high-volume pump agitates the contents of this glass-lined steel tank.

Bedding and fibrous material will break down slowly or not at all in a tank. Nondegradable material leads to sludge buildup or crusts forming on the surface, both of which require vigorous agitation before the tank can be pumped out properly. Such agitation may not be achievable at distances greater than 40 to 60 feet from the agitating device. Agitation while the tank is being pumped down is advised to prevent the settling of sludge and solids. Agitation is accomplished by using high-horsepower, propeller-type agitators or by recirculation with high-capacity pumps (Figure 3). Some pumps combine propeller-type agitators and high-capacity pumps for recirculation and for filling tank wagons or tanker trucks.

Access ramps

Access ramps, slabs, and pumping/agitation platforms should be provided as needed for all-weather access to the tank with agitating, pumping or hauling equipment. Ramps should be no steeper than 5 to 1 for tractor/pump or tractor/agitator access. Grooves or ridges 1 inch or more deep across the ramp should be formed into the concrete before it sets to improve traction. Access ramps for tankers should not be steeper than 10 to 1; 20 to 1 is preferred.

Startup, management

Tanks should be filled with at least 6 inches of water before manure is introduced into the tank to prevent drying of the manure.

Pumping operations should begin before the tank is full to ensure space (safety volume) is always available to hold the 25-year, 24-hour storm (6 inches in Missouri). The DNR guidelines call for pumping the tank when the water level is one foot or more below the full pool level (safety-volume depth).

Safety and appearance

Efforts should be made to make storage structures as aesthetically pleasing in appearance as possible. Grassed areas should be mowed and maintained regularly. If a tank is within public view, it may be desirable to establish a row of trees as a screen. A well-maintained facility is less likely to attract attention and cause controversy than a facility with an offensive appearance.

A fence should be constructed and maintained to prevent access of children, trespassers and livestock to open-top tanks (Figure 4). Post warning signs (DANGER — MANURE STORAGE — KEEP OUT) and keep the gate locked.

Figure 4

Figure 4

Floating bedding covers the surface of this concrete manure storage tank. The fence prevents accidental entry.

Whenever a person enters a storage tank that has contained liquid manure, extreme caution should be exercised to prevent death by asphyxiation from lack of oxygen or the presence of lethal gases. If it is absolutely necessary to enter a manure storage tank or pit, Occupational Safety and Health Administration (OSHA) regulations require the use of specialized safety equipment such as a supplied-air respirator, which supplies grade D breathing air. Alternatively, a self-contained breathing apparatus may be used by those who are trained and familiar with the use of this equipment. Any person entering the tank or pit should wear a rescue harness with a rope to persons outside the tank with a block and tackle for emergency extrication.