Maple syrup, enjoyed on pancakes, in cooking recipes and in cocktails, can be made in Missouri thanks to an abundance of Maple (Acer spp.) trees found in many of parts of the state. Sugar Maples (Acer Saccharum) are the typical tree used in large-scale syrup production, but other common maples (silver, black, red, etc.) and some other species, such as Black Walnut (Juglans Nigra), can also be tapped. Maple syrup production is a family pastime for many Missourians, who either consume their syrup at home or gift their products to others. However, strong demand for local syrup can turn a hobby into extra income for those interested in scaling up their operations.

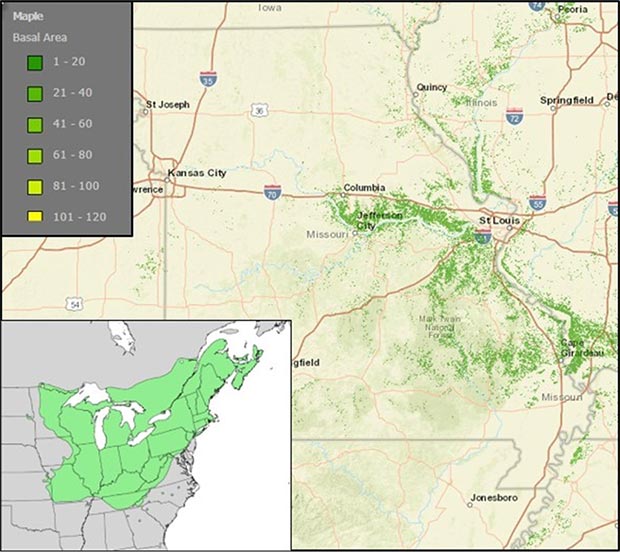

University of Missouri School of Natural Resources graphic using U.S. Forest Service and USDA data.

A 2022 survey of Missouri maple syrup producers (PDF) revealed that respondents produced 480 gallons of syrup, with a median of 10 gallons per respondent; this is likely a conservative estimate. One in four survey respondents sold syrup in 2022 or the previous season, while others produced smaller amounts as a hobby. However, most producers (57%) had either sold syrup at some point or had an interest in sales. With the right knowledge, equipment and environmental conditions, tree-sugaring enthusiasts can earn income from their pursuits to supplement their earnings or — in some cases — make it a business.

A companion to MU Extension’s Marketing Maple Syrup in Missouri, this guide is structured to help maple sugaring hobbyists navigate the process of growing their operation beyond a hobby and into a revenue-generating endeavor. This guide includes information on how to identify capacity and select trees to tap; technology and processing best practices; and tips from active producers on steps taken to break even and begin generating revenue.

Identifying capacity

Missouri sits on the southwestern edge of the native distribution of sugar maple, the tree often tapped for commercial sales (Figure 1). Sugar maples are most prolific where winters are cold and require a hard freeze for winter sap production, and are less common in the southern part of their range, where they tend to be confined to ravines and moist flatlands due to hot and humid summers.

Due to its location at the southern tip of the sugar maple range, Missouri’s maple syrup producers are faced with unique constraints and opportunities. The relative scarcity of sugar maples in Missouri means producers that successfully convert their hobby into sales can capitalize on the high demand for locally produced syrup. Alternatively, producers can tap other maples with lower sugar content, but they will need more sap for the equivalent amount of syrup derived from a sugar maple.

Environmental considerations

On the southern edge of sugar maple’s range, Missouri is susceptible to wider temperature variations than the northern regions. In the 2022 survey of producers, several noted that when they experience mild January temperatures (above 50°F), tapped holes can seal and sap flows slowly to negatively impact production. Multiple producers observed that a down year can have lasting effects, such as needing to reestablish their customer base after production declined during a mild winter.

In Missouri, sugar maple trees are most abundant along the hills of the Missouri River and other waterways in the central and southeast parts of the state (Figure 1). Sugar maples are generally found in soils underlain with limestone, with relatively high pH and adequate water-holding capacity. While sugar maples can — and do — grow in nearly every Missouri county, these conditions are ideal for maximizing production. Even under ideal conditions, sugar maples do not always produce consistent sap quantities. Productivity depends on the age and circumference of the tree, as well as the point in the sugaring season when the sap is extracted. The sap’s sugar content also varies during different periods of the sugaring season.

Production variability

In the early sugaring season (late December to early February), trees have higher sugar content (2–5%), requiring 40–60 gallons of sap for one gallon of syrup. In the later season (February to early March), sugar content is more variable, often containing less sugar (1%), doubling the required sap to around 80 gallons for the same syrup quantity. This variability in sap production among Missouri sugar maples results from both hot summers and mild winters.

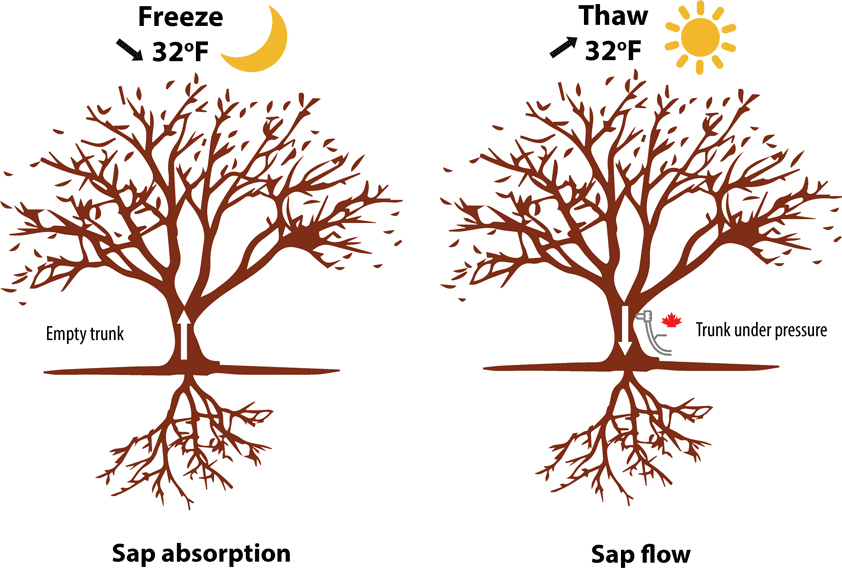

During summer, rising temperatures cause sugar maple trees to respire faster than photosynthesize, diminishing carbon storage and sap sugar content. In early winter, sap flows when daytime temperatures are 30s to mid-40s, and nights are below 32°F (Figure 2). Cold nights allow the trees to cool down and absorb moisture from the ground through its roots. During the heat of day, the tree warms up and the buildup of internal pressure in the trunk drives the sap outwards to the taps. This cycle of above-freezing days and below-freezing nights needs to repeat for several days for the sap to flow. If the weather becomes consistently warm, sap flow stops.

Identifying, selecting and tapping trees

Developed by the Missouri Department of Conservation.

Sugar maple trees typically reach a height of 80–115 feet but can grow as tall as 150 feet. The leaves are deciduous (dropping in the winter), up to 7.9 inches long and wide, palmate (several lobes with midribs radiating from one point), with five lobes borne in opposite pairs. The smallest lobes are on the bottom and the most pronounced notches on the top (Figure 3).

In the spring, signaling the end of the tapping season, the branches develop buds that blossom into bright neon green flowers in panicles (loose branching flowers). Sugar maples are easiest to identify in the fall as leaves transition from green to bright yellow, to fluorescent red-orange (Figure 4). An average mature sugar maple tree, 30–40 years of age, typically produces 9–13 gallons of sap per season, up to 3.2 gallons per day.

Developed by the University of Minnesota Extension (left) and the Missouri Department of Conservation (right).

While other maples (black, red, silver, box elder) can be tapped, their sap’s sugar content is lower. Among them, only black maples approach the sugar content of sugar maples. Sugar maple trees with the greatest exposure to sunlight are ideal for tapping. Generally, a sugar maple tree 8–15 inches in diameter will support one tap. Larger trees, 16–24 inches in diameter, will support two taps; trees greater than 24 inches in diameter will support three taps. Conservative recommendations limit taps to no more than four per tree.

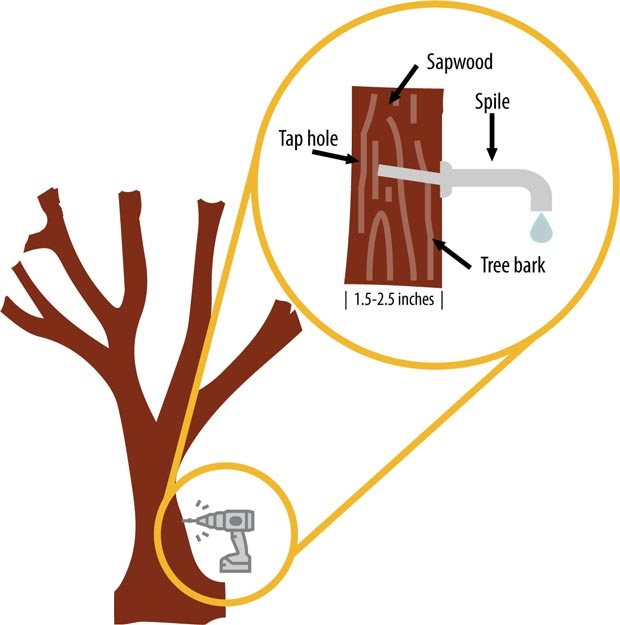

Tap holes should be drilled at a slight incline to allow gravity to dispense sap downward; and at a convenient height for collection — not lower than three feet from the ground (Figure 5). For previously tapped trees, new taps should be at least six inches from former tap holes. Consistently tapping the full circumference of the tree ensures consistent year-to-year flows. Taps are best placed on the south side where sunlight exposure is highest, to increases sap production and flow. Available from maple equipment sellers, a wood-tapping drill bit is recommended as it will remove wood shavings from the hole.

Avoid damaged parts of the tree, and if multiple taps are used, distribute them around the circumference. Most taps will require a 5/16 bit, and holes should be roughly 1½ to 2½ inches deep. When drilling tap holes, white to light brown shavings indicate healthy sapwood. If shavings are dark brown, the tree should not be tapped. Trees should be drilled only once, and wood shavings should be cleared before inserting the tap.

Production technology and best practices

Sap collection equipment

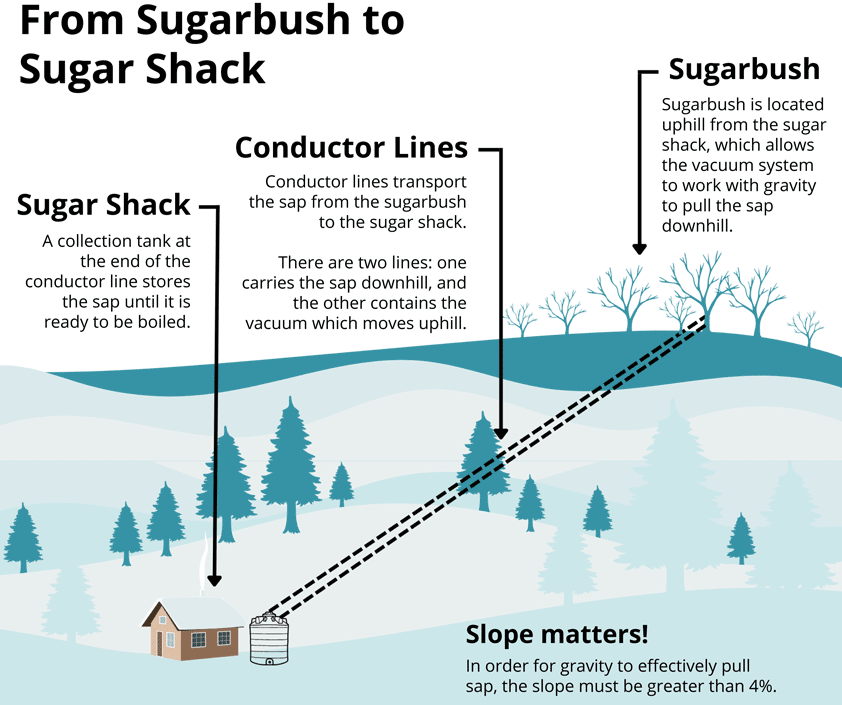

Taps (also called spiles) and 5-gallon buckets or disposable sap sacks (transparent blue plastic bags that block UV rays) are essential for sap collection. Buckets or sap sacks are widely available and are positioned directly under taps. Several producers use utility task vehicles (UTVs) during the sap season to collect from various points on their property. For operations with multiple trees and taps, investments in 3/16 plastic tubing routed to a centralized collection tank greatly reduce the time spent collecting sap. Larger tubing may be required if sap flow becomes restricted during heavy flows. When placing tubing, carefully plan the route to allow sap to travel from tree to tank. There should be enough of an angle (4% at a minimum) for gravity to pull the sap downward through the tube and to the tank.

For tubing systems, position the collection tank at a low point on the property. This ensures that sap from all tubes starts its journey at a higher elevation (Figure 6). Tubing systems can contain either one or two sets of tubes. Natural vacuum systems, typically utilizing one set of 3/16 tubing, rely solely on gravity. Once full of sap, gravity pulls the sap downhill and creates a ‘natural’ vacuum at the top of the line. If using only one tube, a vertical drop of at least 40 feet from the bottom end of the tube to the first tree is recommended. Many tubing installations utilize two lines (“wet and dry”) with a vacuum pump for maximum sap flow; however, this method is discouraged unless 1-inch or larger mainlines are already in place. The ‘wet’ line carries sap from the trees to a centralized collection tank, while the ‘dry’ line, attached to a pump, transfers the vacuum to every tree throughout the sugarbush. Sap releasers are used at the bottom of the line to transfer sap to the bulk storage tank while maintaining the vacuum throughout the network.

The largest producers route their tubing to the location where processing will take place; typically, a small structure known as a “sugar shack.” Sugar shacks take many forms, but all share a louver (a window blind or shutter angled to admit light and air, keep out rain and direct sunshine) as the key design feature. The louver provides a vent for steam to escape when boiling sap. Sugar shacks are often established in existing farm structures suitable for conversion, such as sheds, garages and other detached buildings. Often, the entire process of turning sap into syrup, including bottling and labeling, occurs in a sugar shack.

Boiling and filtering

While the technology for producing maple syrup has evolved, the basic process remains virtually unchanged from when Native Americans first began boiling sap to make syrup. Maple syrup is made by boiling between 20 and 50 volumes of sap (depending on the concentration) over an open flame until one volume of syrup remains. Typically, the boiling occurs in a two-step process, with the first boil done over a wood fire or stove designed to rapidly boil the sap down. Once the sap has reduced to the point where the mixture is roughly 40% sugar, it is taken to a smaller stove, usually propane so that heat can be quickly shut off once the sap reaches 67% sugar (67°Brix) and becomes syrup. Sugar content increases quickly as the process nears its end, which requires tight control of the heat source.

Three different tools can be used to determine the sugar content of syrup:

- Thermometer — if using a thermometer, it should be calibrated at the true boiling point of water (212°F). Syrup at 67 °Brix boils at 7.1°F over the boiling point of water. Note that the boiling point of water can vary +/- 2°F, depending on the barometric pressure at the altitude where the boiling will take place.

- Hydrometer — more accurate than thermometers, hydrometers measure liquid density which indicates sugar levels, utilizing a column of red liquid which indicates the point at which syrup reaches standard Brix at any temperature.

- Refractometer — use light refraction to gauge sugar concentration; a drop of the syrup mixture is extracted with an eye dropper and placed on a prism window where a light read scale determines the Brix content.

During open pan evaporation, water in the sap is gradually boiled off until the desired sugar-to-water ratio is achieved. Syrup boiled too long will eventually crystallize. Conversely, under-boiled syrup will be watery and quicker to spoil. Once the syrup is finished boiling, and still hot, it is filtered to remove impurities and “sugar sand” — crystals made of sugar and calcium malate — before it begins to cool and thicken. While not toxic, the crystals impart a gritty texture, resulting in a lower quality product. Smaller operations sometimes use cheesecloth for filtration, while larger operations invest in designated maple syrup filtering kits. Metal filter presses are sometimes, used but can cost thousands of dollars. For the simpler method of gravity filtering, syrup filters are widely available and at a much lower price point, typically $20–$40.

Reverse osmosis

An affordable technology, reverse osmosis involves pre-processing sap before boiling. Reverse osmosis involves applying pressure to the sap and forcing it through a membrane (filter) where only freshwater molecules can pass through. Left behind is a highly concentrated mineral and sap solution that can be boiled in half the time, reducing both the required fuel and labor. Small-scale reverse osmosis systems can be purchased for a few hundred dollars, whereas larger commercial size systems can cost thousands of dollars.

Some producers opt to construct their own systems, but this requires knowledge, skill and time. Calculating the return on investment before purchasing or building a reverse osmosis system is crucial to determine how implementing the technology will impact an operation. Producers who have implemented the technology note that the equipment usually pays for itself in just one or two seasons and greatly reduces their time spent in production, which is highly valued.

Grading and packaging

Filtered syrup is best packaged and graded while still hot, at a temperature between 180 and 189°F. To ensure sterilization of the bottle, the syrup needs to maintain a temperature higher than 180°F for at least 10 minutes in the bottle. To avoid the formation of sugar sand, or “nitre,” the syrup’s temperature must also be kept below 190°F. Finished maple syrup can be placed in metal, glass or coated plastic containers, depending on the volume and target customer. After sealing, the hot containers are inverted, sterilizing the cap with the hot syrup. Information on grading, packaging and labeling the finished product can be found in MU Extension’s Marketing Maple Syrup in Missouri guide

(extension.missouri.edu/dm3036).

When grading maple syrup, both color and taste are important factors. While color is easily observable, taste can be influenced by various issues arising from the boiling process. Off-flavors can develop when there are contaminants present in the boiling apparatus, such as disinfectants, microorganisms or fermentation products. Metallic flavors can sometimes be imparted on the syrup when stored in metal containers. Additionally, a “buddy sap” flavor can develop when sap is collected late in the sugaring season when the maple trees have started to bud. It is important to taste test the syrup when grading to ensure that syrup is not labeled Grade A based on color alone.

Making a profit: tips from maple syrup producers

Achieving economy of scale

Of the 50 producers interviewed, only a few were generating significant revenue from their efforts. One crucial characteristic shared by these operations was an abundance of mature sugar maple trees on privately held property. For example, one of the largest revenue-generating operations involved 500 taps which produced 100 gallons of syrup, generating roughly $30,000 in net sales annually. The largest operations have 700 or more taps. Like any product, achieving an economy of scale (cost advantages gained from increasing output) is important for long-term profitability. Assessing how much sugar maple forested acreage can be accessed to reach similar levels of production is a critical first step.

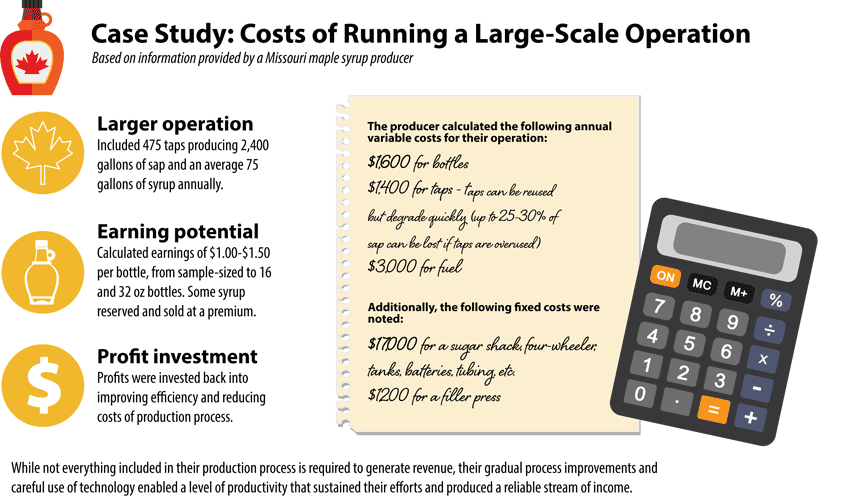

For most Missouri producers, even the largest, income generated from maple syrup is supplemental. None of the surveyed producers reported that revenue from maple syrup alone was sufficient to pursue the activity full-time. Successful operations typically offered maple syrup as one of several products. One producer noted that maple syrup was one of 50 products available from their operation. In a good year, maple syrup sales made up 13% of farm revenue; in a bad year, it accounted for 5%. Figure 7 offers a case study from a Missouri maple syrup producer calculating the costs associated with running a large-scale operation.

Keeping records

Beginning producers, starting with just a few trees and enjoying the activity as a hobby, may overlook the importance of tracking costs and hours required for syrup production. However, as they grow and start selling products, it will be vital to keep records to understand profitability and meet tax obligations.

Breaking down costs by fixed and variable expenses is a good first step when the season begins. Fixed costs are typically upfront purchases needed for syrup production, such as an evaporator, firebox and tools. Variable costs are purchases that fluctuate with syrup volume (e.g. taps, bottles, wood, etc.). Labor time, provided by the producer or other sources of help, also count in variable costs.

Keeping records regarding sap collection and processing figures, such as Brix levels, is important for understanding and replicating results for future production efforts. A reliable syrup “recipe” will be valued by customers and encourages repeat business.

Tracking sales information, including timing, locations, pricing, and customer data, provides valuable insights for expanding the syrup business and understanding the most profitable strategies. Good record-keeping can also be beneficial at tax time, allowing deductions for business costs associated with syrup sales income. Consulting with an accountant who specializes in agricultural income is a wise step to ensure needed information is collected for tax forms and to gain a better understanding of profitability.

Achieving a break-even point and beyond

Even the most successful producers often didn’t see a profit in the first few years of sales. Several producers noted that their first few years of production involved substantial trial and error, sometimes resulting in what was referred to as “maple ash” or “brown water” (an inferior product unsuitable for sale). The trait shared by producers seeing the highest profits was a commitment to learning and gradual process improvement. Additionally, the most successful producers tended to be highly skilled in re-purposing and refurbishing used equipment, finding creative uses for items already at their disposal.

A labor of love, it is common for family and friends to assist in production in exchange for a taste of the final product. Taking place during a dormancy period for most agricultural producers, maple syrup production can serve as a revenue-generating stopgap to fill an otherwise unproductive period before the growing season for row crops, pastured animals and other agricultural pursuits begins. While personal and family labor is often not factored into the cost of making syrup,understanding the time spent is valuable for identifying areas where labor savings can occur, especially if producing syrup for profit. One producer noted that, after calculating the time invested in the entire process, he earned less than $5 per hour of effort in revenue.

The top piece of advice that producers seeing the highest profits gave was to invest in a reverse osmosis system. As the boiling process is time-intensive, sometimes taking as long as 24 hours depending on the volume, halving the time and fuel requirements greatly reduces both labor and fuel costs. Given the long boiling period, the reduced fuel usage can result in significant cost savings. Another way to cut costs is by having ready access to an abundant supply of firewood. Several producers noted that their investment in reverse osmosis technology was the key factor that made their operation profitable.

Finding savings through used and repurposed equipment, along with utilizing reverse osmosis technology to decrease labor and fuel costs, are key steps in reducing production costs. Recording production costs, including labor hours, and revenue each season will provide the necessary information to track profitability. Free worksheets available through the University of Missouri Center for Agroforestry (Tree Sugaring Resource Hub) can be used to enter information weekly as trees are tapped and maple syrup is eventually sold.

Funding for this publication was made possible by the U.S. Department of Agriculture’s (USDA) Agricultural Marketing Service through grant 21ACERMO1005-00. Its contents are solely the responsibility of the authors and do not necessarily represent the official views of the USDA.