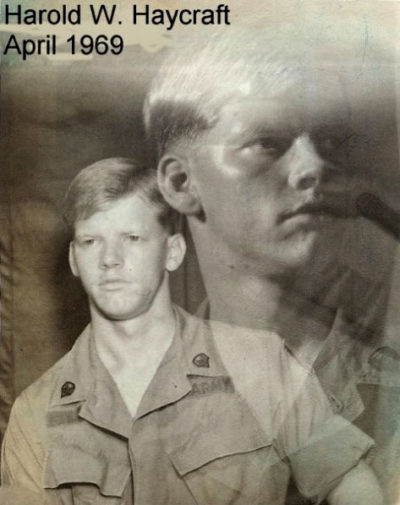

Harold Haycraft, founder of Hannibal Machine Inc., remembers the date clearly: Aug. 6, 1968.

“It’s hard to forget,” he says from his office in Hannibal. He was inducted that day, serving in Vietnam from 1969-70 as a Huey crew chief. The Hueys sprayed Agent Orange. “Our flight sergeant said it’s as safe as suntan lotion, totally safe,” he recalls.

He was then trained in medevac. He also had to pull guard duty five nights a week. He’s now considered partially disabled as a result of exposure to Agent Orange and other complications of his military service but says he doesn’t regret it one bit.

“The Army taught me to get out of bed in the morning, that’s the biggest thing,” he says.

“Also a good work ethic,” chimes in his son and the firm’s manager, Scott.

“Right, a good work ethic.”

This easy back and forth characterizes the Haycrafts’ approach to management, with a still hale Harold mainly handling and supervising manual operations.

His Facebook page lists his title as president and floor sweep.) Scott handles the computer numeric controlled (CNC) machinery that cuts, grinds, drills or shapes the material.

Declaring the firm a service-disabled veteran-owned small business proved fruitful, father and son say, in securing some federal government contracts.

By law, the federal government must set aside not less than 3 percent of the total value of all prime contracts and subcontracts for service-disabled veteran businesses.

Harold Haycraft (left) with son, Scott, manage Hannibal Machine together.

“But service-disabled status doesn’t mean anything is guaranteed,” says Scott. “You still have to provide quality work at a good price. Nothing is given or granted. That’s a very common misconception.”

More fruitful, they say, has been their collaboration with Chris Shoemaker, former procurement specialist for the University of Missouri Extension-Macon County Procurement Technical Assistance Center (PTAC). PTAC is a BDP program charged with helping firms, including those owned by veterans, women and disadvantaged individuals, secure good federal, state and local government contracts.

Shoemaker helped the Haycrafts pull back the curtain of government contracting to show them How to register with the System for Award Management (SAM) to access the thousands of daily contracting opportunities in FedBizOps (the U.S. government’s main contracting database); nail down just the right North American Industry Classification System (NAICS) codes, used by all federal agencies and numerous industries to classify businesses; and then pore over the resulting bids.

“Chris would send us contracts to review,” says Scott. “He’d say, ‘Hey you missed this checkmark on page 10, that delivery date on page 9.’ He’s been great to work with.”

In spring 2016, Shoemaker also introduced them to Orbital ATK Small Caliber Systems, arguably the world’s leading ammunition producer, and its Lake City plant in Independence. The firm secured one machining contract with Orbital ATK, which led to another, then a third, then more.

As a direct result, the Haycrafts have been able to add a skilled CNC machinist, bringing the total number of employees to seven, and are thinking about adding more people.

“We were wary about doing government work,” says Scott. “But with the direction of Chris and filtering results on FedBizOps, opportunities have really opened up for us nationwide.”

These contracts include work for the Navy, U.S. Army Corps of Engineers and even the U.S. Department of Transportation’s Saint Lawrence Seaway Development Corporation. Previously, they had been heavily reliant on local industries, now all but vanished. In the process, the firm’s revenue has been boosted closer to the $1 million mark.

“Now we’ve developed some stability, turned a corner,” says Scott. Their interaction with MO PTAC, he says, helped them develop the confidence to pursue only the contracts right for them.

“PTAC helped us narrow our vision.”