Wheat silage as a feed for dairy cows has become popular recently in Missouri, even though little information about nutrient content and optimum cutting stage is available. Some recent research at MU provides new information about wheat silage for dairy cows. This new information includes the changes in energy, protein and minerals with stage of maturity at harvest and recommendations for cutting and storage. In general, most of this information probably applies to other small grain silages, such as oats and barley, for which similar information is scarce.

Increased use of wheat silage

Wheat is being used more and more as a silage by dairy farmers. Several desirable characteristics of wheat as a forage crop caused increased use:

- Wheat can provide a fall cover crop and/or fall pasture; it can be grazed in the fall with little effect upon grain or forage yield the following spring.

- Wheat is suitable for many of the soils and climatic conditions of Missouri.

- Wheat is a dependable crop because it grows mostly in the spring when moisture usually is adequate.

- Wheat forage can be double cropped with a number of crops.

- Wheat silage allows more complete use of silos and silage handling equipment.

- Wheat silage can provide an interim forage during the time when the previous year's hay or silage has run out and the present year's has not been harvested.

- If properly ensiled and fed in combination with a properly balanced grain ration, wheat silage can maintain high milk production.

- Wheat taken off as silage allows better growth of double cropped new seedlings.

- Wheat silage may be successfully stored in upright or horizontal silos.

There are some disadvantages of wheat for silage:

- Wheat to be used as silage must be harvested quickly to preserve quality.

- Wheat harvest time coincides with planting time for other crops; this may create a labor shortage.

- Wheat silage tends to be bulky after removal from silos and should be weighed carefully to ensure that cows are getting enough dry matter.

Nutrient content of wheat silage

Recent research at MU has helped determine the nutrient content of wheat silage and the optimum stage of maturity for harvest.

Wheat from four different farms in northwest Missouri was sampled at about one week intervals from March to June 1976. These samples represented wheat harvested from early (emerging) to late (ripe seed) stages.

The wheat forage samples were dried, ground and analyzed for detergent fiber, digestibility, protein and net energy. Detergent fiber analysis gives more accurate estimates of forage energy values than crude fiber analysis. Samples of wheat from the boot, mid-boot and dough stages were analyzed for calcium and phosphorus.

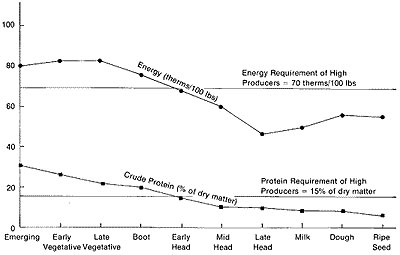

The results of analyses are in Tables 1 and 2 and Figure 1. Although wheat was sampled on four different farms, nutrient contents were almost identical for the four farms at each stage. Therefore, each value in Tables 1 and 2 and Figure 1 is the average of the four samples cut at each stage.

Table 1. Detergent fiber, digestibility, protein and net energy of wheat silage.

| Cutting date | Stage | Neutral deter- gent fiber | Acid deter- gent fiber | Acid deter- gent lignin | Cellulose | Crude protein | In vitro dry matter digest- ibility | Net energy lactation per 100 pounds |

|---|---|---|---|---|---|---|---|---|

| Percent of dry matter | ||||||||

| 3-31-76 | Emerging | 46.10 | 25.08 | 4.97 | 20.11 | 30.90 | 90.59 | 80 therms |

| 4-7-76 | Early vegetative | 46.15 | 28.37 | 4.50 | 23.87 | 26.30 | 93.36 | 83 therms |

| 4-14-76 | Late vegetative | 46.63 | 28.76 | 4.33 | 24.50 | 22.45 | 93.53 | 83 therms |

| 4-21-76 | Boot | 53.10 | 32.25 | 4.64 | 27.59 | 20.87 | 89.22 | 76 therms |

| 4-26-76 | Early head | 56.73 | 37.24 | 6.07 | 31.18 | 15.31 | 83.12 | 68 therms |

| 5-10-76 | Mid-head | 61.45 | 39.01 | 6.71 | 31.55 | 11.26 | 78.89 | 61 therms |

| 5-19-76 | Late head | 67.99 | 43.42 | 9.39 | 34.04 | 10.27 | 67.51 | 46 therms |

| 5-25-76 | Milk stage | 60.30 | 39.97 | 8.92 | 31.03 | 8.99 | 64.84 | 49 therms |

| 6-1-76 | Dough stage | 58.77 | 38.73 | 8.06 | 31.10 | 8.49 | 72.07 | 56 therms |

| 6-15-76 | Ripe seed | 59.79 | 34.05 | 7.28 | 26.77 | 6.78 | 71.22 | 55 therms |

The fiber fractions of the plant (Table 1) increased very little in the first three stages (emerging, early vegetative and late vegetative) because the plants were growing rapidly and were producing a large amount of highly digestible, nonfibrous material. Consequently, net energy of lactation in these first three stages was high and actually increased slightly.

In the next four stages (boot, early head, mid-head and late head) fiber content increased rapidly as indicated by the rise in detergent fibers. Consequently, energy decreased rapidly.

In the last three stages (milk, dough, and seed) seed carbohydrates were being formed and tended to dilute out and decrease fiber. Consequently, net energy increased slightly in these latter three stages, and protein was extremely low.

The net energy content of wheat cut at the boot and the early head stage was 76 to 68 therms per 100 pounds, respectively. This means that at these two stages, wheat silage appears to be similar to corn silage and better than many hays or haylages in energy content. Note that once the wheat got into the mid-head stages, energy decreased quite rapidly.

Crude protein (Figure 1, Table 1) was high in early stages and declined to a low level in the seed stage. Crude protein was about 21 percent and 15 percent at the boot and early head stages, respectively; this means wheat was superior to grasses and equal to legumes in protein content at these stages.

The 3 percent unavailable protein was about the same as has been found in most other forages.

Calcium and phosphorus content of wheat cut at the boot, mid-head and dough stages is in Table 2. Calcium content was very low compared to most forages at the boot stage. A 50 percent reduction occurred from boot to dough.

Phosphorus content was similar to levels found in most forages and declined about 25 percent from boot to dough.

Table 2. Calcium and phosphorus content of wheat.

| Growth stage | Calcium | Phosphorus |

|---|---|---|

| Percent of dry matter | ||

| Boot | 0.24 | 0.35 |

| Mid-head | 0.19 | 0.34 |

| Dough | 0.10 | 0.28 |

| Average | 0.18 | 0.31 |

Optimum cutting stage

The fiber, energy, protein, calcium and phosphorus data of Tables 1 and 2 and Figure 1 indicate that the best time to cut wheat as a forage for dairy cows is from boot to early head. At these two stages, energy was 68 to 76 therms per 100 pounds and crude protein was about 15 to 21 percent. The high producing cow should be getting about 70 therms of energy per 100 pounds dry matter and 15 percent crude protein, according to National Research Council recommendations. Thus, wheat for silage cut by boot or early head will contain enough energy and protein when fed in combination with a balanced grain ration to sustain high milk production.

Harvest probably should begin when the wheat just reaches the boot stage; if harvest proceeds quickly without interruptions from weather, etc., the last silage cut should be in the early head stage. Letting wheat progress to mid-head decreases energy and crude protein and creates a need for greater supplementation. Figure 1 illustrates this point: Two horizontal lines represent energy and protein requirements of the high producer. Wheat cut at boot and early head has energy and protein content above levels required for high producers. However, cows cannot eat enough wheat silage cut at boot and early head to meet energy requirements, and concentrates will be needed. Wheat cut at mid-head and later stages is below energy and protein requirements for high producers.

Although greater yields most likely would result if wheat is left to mature to the late head, milk, dough or seed stages, the wheat has less energy and protein (about 50 therms per 100 pounds and 8 to 10 percent crude protein). This is no better than average hay. Cows are not likely to produce at their maximum when consuming wheat forage cut later than early head.

Other cereal grains

Few data are available to indicate the optimum stage for harvest of other cereal grains for silage. Research with wheat suggests that other cereal grains be harvested from boot to early head for high quality silage.

Supplementing wheat silage

Wheat silage cut at boot or early head contains high levels of energy and protein and is similar to alfalfa haylage. On the other hand, wheat silage is extremely low in calcium (Table 2) — lower than most other forages. Therefore, when wheat silage is used, extra calcium must be used in the grain mix to bring calcium levels up to recommended levels.

When dairy producers change from corn silage to wheat or other small grain silages, they must reformulate the grain ration. Reformulation will often mean lowering the protein and increasing the calcium in the grain. The amount of grain fed usually should be increased because corn silage is normally higher in energy than wheat, grass, and small grain silages.

Storage management

Ensiling and maintaining top quality silage is probably more difficult than corn and sorghum silage because, like other cereal, grass, and legume silages, wheat silage can spoil easily. Management practices that will help ensure good quality wheat silage are:

- Stage of maturity is most important. If wheat silage is cut too late, energy and protein content will be low, and even the best management will not improve it. The optimum time to cut wheat for silage is from boot through early head. Because this period lasts only about one week, harvesting must begin early enough to be sure that the last wheat ensiled is in the early head stage. Although dry matter yields would probably increase if wheat were harvested later, quality declines rapidly. Also, if dry matter gets too high, wheat will not ensile properly and may be difficult to pack.

- Ensile at the proper dry matter content to minimize losses and heating. The proper dry matter content depends upon the type of silo:

- Trench or bunker: 30 to 35 percent dry matter

- Conventional upright: 35 to 45 percent dry matter

- Gas-tight upright: 35 to 50 percent dry matter

Because dry matter increases as harvest proceeds, dry matter at the beginning of harvest should be on the low side so that the last wheat ensiled will not be too dry. For example, if the first wheat put into the trench or bunker is about 30 percent dry matter, the last silage put in probably will be about 35 percent. Wilting will be necessary to get dry matter content into this range if wheat for silage is cut at the boot stage. The last few loads may be direct cut to improve final packing.

- Proper cutting length is about 3/8-inch but is highly dependent upon tractor power take-off speed, sharpness of knives, ground speed, etc. As a rule of thumb, a few long pieces of wheat will be present; but most pieces should be less than 1-1/2 inches.

- Rapid filling and adequate packing keep spoilage at a minimum, prevent dry matter losses and minimize heat damaged protein. Silos should be filled within one to two days. Packing should be done continually with a wheel tractor as filling occurs. As soon as the last wheat is in the silo and is packed well, immediately cover the top with dark heavy plastic (4 mm in thickness). Covering at the end of each day of filling will help. A delay of only one or two days in covering the silage can result in up to 25 percent loss in dry matter. Each square foot, or five cents worth of plastic cover, may save a cubic foot of silage, or about 30 cents worth; thus you save about 25 cents worth of feed per square foot of surface area. Weight down the plastic cover to provide a tight seal so that all air is excluded.

- If the preceding practices are followed. spoilage should not occur and heat damaged protein should not be present. However, if the silage has a dark brown to black appearance and has a sweet smell like caramel or tobacco, heat damage may be present. If heat damage is suspected, have the forage analyzed for heat damaged protein, and make adjustments for protein content of the ration quickly to maintain top milk production.