Evaluation of beef quality and composition is important to cattle producers, meat packers and retailers, and consumers. Consumers desire cuts of beef that are lean, nutritious, and possess desirable eating characteristics. Meat researchers have developed reliable methods for measuring the factors that influence eating characteristics and factors affecting yield of lean cuts. Using these evaluation techniques, producers and packers can produce and sell carcasses that meet consumer demand.

This guide provides information about standard U.S. Department of Agriculture beef carcass yield and quality grading systems. Other useful and accurate evaluation procedures will also be introduced.

Beef carcass grading is divided into quality grading and yield grading.

Quality grading

Quality grades indicate the factors related to the sensory characteristics of tenderness, flavor, color, texture and juiciness. The quality grade is intended to reflect the cooked product's overall acceptability.

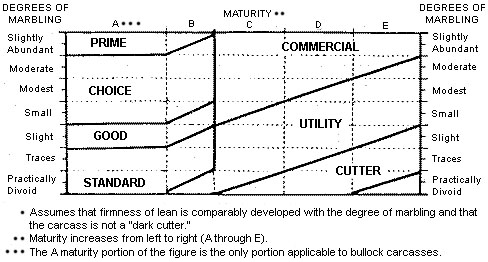

The USDA quality grades for steer and heifer carcasses are prime, choice, good, standard, and utility. These grades are determined by balancing maturity and degree of marbling.

Maturity refers to the physiological age of the live animal. Maturity in the carcass is determined by the degree of ossification (bone development) of the split chine bones (back bones) and the color and texture of the cut lean surface.

Cartilage changes into bone as the animal matures. This process of ossification proceeds from the back toward the front portion of the vertebral column. The degree of ossification in the vertebral buttons near the thorax, which is the cavity containing heart, lungs, etc., is the most useful in evaluating maturity. Rib bones also become flatter and whiter as the animal matures.

Meat from young animals is lighter colored and finer textured compared to older beef. Generally, a fine-textured lean will be more tender than a coarse textured lean. Carcass maturity is closely related to beef tenderness. As the animal matures, changes in the connective tissue cause the meat to be less tender.

The degrees of maturity are A, B, C, D and E. Age ranges for these maturity groups are approximately

| Maturity group | Age |

|---|---|

| A | 9 to 30 months |

| B | 30 to 42 months |

| C | 42 to 72 months |

| D | 72 to 96 months |

| E | more than 96 months |

Dark-cutting beef is not necessarily from older animals but can also result from cattle that were physiologically stressed before slaughter. Dark-cutting beef is highly discriminated against by consumers and retailers. Dark-cutting beef may be reduced up to one full quality grade.

Marbling is fat within the muscle and is evaluated in the rib eye between the 12th and 13th ribs. The 10 USDA degrees of marbling are abundant, moderately abundant, slightly abundant, moderate, modest, small, slight, traces, practically devoid, and devoid. Marbling has a strong correlation with the juiciness and flavor of beef.

Final quality grades are arrived at by a composite evaluation of maturity and marbling.

Yield grades

Yield grades estimate the quantity or the amount of closely trimmed boneless retail cuts from the loin, round, chuck and rib. There are five USDA yield grades, 1 through 5. Yield grade 1 carcasses have the highest yield of retail cuts and yield grade 5, the lowest.

The expected boneless retail yield from the round, loin, rib and chuck is as follows:

| Yield grade | Percent of carcass weight in boneless, uniformly trimmed retail cuts |

|---|---|

| 1 | more than 52.3 |

| 2 | 52.3 to 50.1 |

| 3 | 50.0 to 47.8 |

| 4 | 47.7 to 45.5 |

| 5 | less than 45.5 |

These yield figures are sometimes used in carcass show results as a measure of cutability.

Yield grade also can be used to predict the total retail cuts from a carcass or quarter.

Total percent retail cuts (closely trimmed, semi-boneless)

| Yield grade | Carcass | Forequarter | Hindquarter |

|---|---|---|---|

| 1 | 82 0 | 84.0 | 79 9 |

| 2 | 77 4 | 79.0 | 74.9 |

| 3 | 72 8 | 75.6 | 69.9 |

| 4 | 68.2 | 71.4 | 64.9 |

| 5 | 63.6 | 67.2 | 59 9 |

The USDA yield grade is based on four factors:

- Hot carcass weight (pounds)

- Rib eye area at the 12th rib (square inches)

- Adjusted fat thickness over the rib eye at the 12th rib (inches)

- Percent kidney, pelvic, and heart (percent of carcass weight).

These measurements are used in the official USDA formula as follows:

Yield grade = 2.5 + [(2.50 x adjusted fat thickness, inches) + 0.2 percent of kidney, pelvic, and heart + (0.0038 x hot carcass weight, pounds) - (0.32 x area rib eye, square inches)]

When computing yield grades, any decimal is dropped; yield grades are presented as whole numbers. Care and accuracy of these measurements are essential to derive reliable estimates of the cutability. The USDA grader, in practice, estimates the factors and uses a short-cut formula.

Fat thickness

The amount of fat on a beef carcass has the greatest effect on the percent retail yield. As the percent fat increases, the percent muscle decreases. Fat thickness is measured at a point three-fourths of the length of the rib eye (longissmus) muscle from the chine bone, perpendicular to the surface fat, at the 12th rib. This measurement may be adjusted according to the total amount of fat on the carcass.

Rib eye area

Total square inches of rib eye is used to estimate muscular development of a beef carcass. This measurement can be taken objectively between the 12th and 13th rib. A calibrated transparent plastic grid placed over the rib eye is commonly used to determine the area.

An alternative method is to trace the perimeter of the rib eye on acetate paper and calculate the area with a compensating planimeter, which is an instrument that measures area of irregularly shaped objects.

Hot carcass weight

Hot carcass weight, or 102 percent x chilled carcass weight, is the weight of the carcass after slaughter. The carcass weight has an inverse effect on the percent retail yield.

Kidney, pelvic, and heart fat

The amount of kidney, pelvic and heart fat is fat accumulated in the body cavity of the carcass. The weight is reported as a percent of the carcass weight. The range of kidney, pelvic and heart fat is 1 to 8 percent (with a typical average of 3.5 percent).

Yield grades estimate the proportions of lean and fat. Meat graders determine yield grades with fast, simple visual appraisals of fat and muscle of the carcass. Fat thickness, hot carcass weight and rib eye area are objective measures with kidney, pelvic and heart fat being a subjective measure.

USDA grading is done on a voluntary basis by the packer. The packer absorbs the cost. When a carcass is submitted for grading, it must be both quality and yield graded.

USDA grades should not be confused with the USDA inspection for wholesomeness.

Beef carcass evaluation

The purpose of beef carcass evaluation is to assist beef producers in:

- Producing high-quality beef carcasses

- Producing high-yielding beef carcasses

- Identifying superior lines of breeding stock

- Promoting a desirable, marketable product.

Improving the efficiency of beef cattle production is important to feeders, cow/calf ranchers and seed stock producers. Feeders can evaluate their feeding and management practices with cutability scores or the percentage or number of their cattle grading choice. cow/calf ranchers may use grades to rank or performance-test their stock. Seed stock producers can ultimately use quality and yield grades in sire evaluation.

Some other guidelines or indexes that may be useful in beef carcass evaluation are a growth factor or loin eye index.

Growth factors can be used to express the composition of growth. Expressing the pounds of retail cuts per day of age is one method.

This figure is determined by this formula: pounds of trimmed retail cuts per day of age = (carcass weight x cutability) divided by age in days.

Example A 600-pound carcass, 400 days old with a yield grade 3 (50 percent retail yield) produces 0.75 pounds of retail cuts per day of age:

(600 x 0.5) ÷ 400 = 0.75 pounds of retail cuts per day of age.

Loin eye area has been highly correlated to the percent muscle in a carcass. A goal of progressive beef producers is to produce cattle yielding at least 2 square inches loin eye area per 100 pounds of carcass.

Example

A 550-pound carcass with a 12.5 square inch loin eye would yield 2.27 square inches loin eye area per 100 pounds of carcass (12.5 ÷ 5.5 = 2.27 square inches loin eye area per 100-pound carcass).

Use of the USDA's Beef Carcass Data Service is a service designed to provide carcass data to breeders or others who don't own the animals at the time of slaughter. Cattle are ear tagged with USDA ear tags and upon slaughter the proper quality and yield grade data are forwarded to the purchaser of the ear tags. This is especially helpful to seed stock producers.

For information on source of ear tags and cost of the service, contact Livestock Division, Agricultural Marketing Service, U.S. Department of Agriculture, Washington, D.C. 20250.