Dairy heifers are the foundation of any dairy enterprise and directly affect future profitability. Because replacement heifers represent a negative cash flow, this aspect of the dairy operation is often neglected. Unfortunately, this neglect often costs producers large amounts of money.

The goals of a heifer program should be to achieve the proper size and weight for the particular breed being raised and to calve by 22 to 24 months of age. Missouri data indicate an average age at first calving of 27 to 28 months. The lost net income per heifer is estimated to be at least $1.50 per day for each day over 24 months of age until freshening.

How the heifer program is managed determines whether farm-raised heifers will be available to maintain the herd or whether off-farm purchases will be required. Table 1 shows the number of heifer calves needed for one replacement heifer with different heifer mortality and culling rates.

Table 1. Heifer calves needed for one replacement heifer with different mortality and culling rates.

| Heifer calf mortality rate (percent) | Heifer culling rate (percent) | ||||

|---|---|---|---|---|---|

| 4 | 6 | 8 | 10 | 12 | |

| 5 | 1.10 | 1.12 | 1.15 | 1.17 | 1.20 |

| 10 | 1.16 | 1.19 | 1.21 | 1.24 | 1.27 |

| 15 | 1.23 | 1.26 | 1.28 | 1.31 | 1.34 |

| 20 | 1.30 | 1.33 | 1.36 | 1.39 | 1.43 |

| 25 | 1.39 | 1.42 | 1.45 | 1.49 | 1.52 |

Dry cow nutrition

Management of cows during the dry period affects the subsequent calves that will serve as replacements. Cows should be adequately fed to maintain body condition, but not overfed to the extent that surplus energy results in abnormal growth of the fetus during the last trimester. Generally, 7 pounds of grain would be the maximum fed to the cow during this period if forage quality is good. Since dry matter intake will decrease by 40 percent or more during the few days before calving, it is important to feed a palatable ration, because it directly affects subsequent production of the cow.

Ideally, cows should be vaccinated at dry-off and again when moved from the “far-off” dry group to the “close-up” dry group. This schedule provides maximum immunity in the colostrum for the newborn calf. Producers should work closely with their local veterinarian to develop herd health programs that fit their area and herd needs.

Birth

About 5 percent of calves are born dead (stillbirths), but many of these deaths can be prevented if someone is present at birth to give assistance. Too often assistance is given only after the cow or calf is in critical condition. Cows should be checked every hour after labor begins. Data from Ohio State University suggested that intervention should occur after one hour once feet and/or the “water sac” was visible (stage II of labor). Several management techniques at birth can increase the likelihood of a healthy calf, but starting with a clean, dry calving area is foremost.

At birth, tie the umbilical cord about two inches from the body with a string that has been kept in a 70 percent rubbing alcohol solution and dip the navel in a disinfectant such as a 7 percent tincture of iodine solution to prevent the development of septicemia (joint ill disease). In addition, bacterial infections of the navel can lead to serious arthritis, which is difficult to treat.

The calf should receive about 2 quarts (4 to 5 percent of body weight) of colostrum as soon as possible after birth, preferably in the first hour of life and again in six to 12 hours. The intestine of the newborn calf is able to absorb maternally derived immunoglobulins (antibodies) contained in colostrum directly into the bloodstream. The ability of the calf to absorb these colostral antibodies is greatest in the first hour after birth and remains fairly constant for up to six hours. It decreases to 50 percent by 12 hours of age. By 24 hours of age, the calf absorbs less than 50 percent.

Colostrum is important for providing antibodies that give the newborn calf resistance to disease, but it also acts as a mild laxative, which aids in removing digestive residue from the intestine of the calf. Table 2 lists the types and purpose of the different immunoglobulins. Colostrum is also high in nutritive value, particularly vitamin A or its precursor carotene, B vitamins, proteins, fat and minerals.

Table 2. Types of immunoglobulins (Ig) and their functions.

| Type | Percent of total Ig | Provides immunity against |

|---|---|---|

| IgG | 80–86 | Systemic infections |

| IgA | 7–10 | Intestinal infections |

| IgM | 7–10 | Systemic infections |

Factors affecting the passive transfer of colostral antibodies to the calf include the mass of immunoglobulins consumed, how soon colostrum is fed after birth, method of feeding, and genetic, physiological and environmental influences. Of these, the most important are mass of colostral antibody consumed and the timing after birth.

In the late 1970s researchers at the University of Arizona developed a method to estimate the antibody content of colostrum. The device used, known as a colostrometer, can be easily used on the farm. The colostrometer is simply a hydrometer specially calibrated to measure specific gravity of the colostrum, which is directly related to antibody concentration. By using this instrument, the producer can estimate the quality of colostrum collected and determine if it should be fed and whether it can be frozen for later use. Colostrum frozen for later use should be labeled to identify the cow source as well as the date of collection.

Another method of measuring the quality of the colostrum is the Brix refractometer. A single drop of the colostrum is placed on the device and read. The manufacturer and research suggest that if the readings are greater than 22 percent, the colostrum is of high quality (more than 50 grams of IgG per liter) and should be fed to newborns on their first and second feedings. Readings of 18 to 22 percent suggest moderate quality colostrum and can be fed for second and third feedings. Readings less than 18 percent suggest low quality colostrum and should not be fed to newborn calves for transfer of antibodies. This method is quick and reliable and does not require colostrum to reach room temperature or settle before reading as in other methods.

Liquid feeding

The milk-feeding period in most calf programs is normally 5 to 8 weeks for large-breed calves and 5 to 10 weeks for small-breed calves. Liquid feeds commonly used are whole milk, fresh or fermented colostrum, waste or discard milk and milk replacer. Which product should be fed to the young calf? Each producer will have a preference, but economics should also be considered. Regardless of the system selected, the amount fed should be about 8 percent of body weight during the first two weeks and 8 to 10 percent of body weight until weaning.

If waste milk is fed, certain precautions should be followed:

- Do not feed to newborn calves on the first day of life, because the intestine is permeable to bacteria that cause illness.

- House calves individually to prevent suckling one another to reduce the transmission of infectious microorganisms that cause mastitis.

- Follow the precautions when feeding milk from antibiotic-treated cows to calves intended for meat production.

- Know the health status of the cows from which waste milk is obtained. Unless milk is pasteurized, do not feed milk from cows shedding bovine virus diarrhea (BVD) or Johne’s disease or from cows infected with E. coli or bovine leucosis virus (BLV).

The purpose of milk replacers is to take the place of whole milk when it is not available or economical or when there are health concerns as mentioned previously. Generally, it takes one pound of milk replacer for each gallon (8.6 pounds) of whole milk.

As a rule of thumb, a quality milk replacer should contain 20 percent protein and a minimum of 15 percent fat; 20 percent fat is recommended during the winter, and less than 0.15 percent fiber. A high-quality replacer will have the majority of the protein and fat coming from animal sources. Read and follow the label for proper mixing and feeding of the replacer.

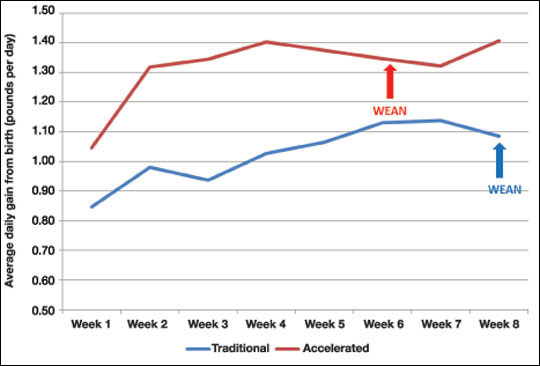

More recently, some producers have begun to use accelerated or intensified milk replacer feeding. This entails feeding a milk replacer high in protein and lower in crude fat (28 percent and 15 to 25 percent, respectively) compared with more traditional milk replacers with 20 percent crude protein and 20 percent crude fat. In most traditional milk replacer feeding programs, a constant amount of milk powder (about 10 ounces) is fed each feeding for 8 weeks or until calves begin to consume 1.5 to 2.5 pounds of calf starter for a minimum of two to three days. Conversely, an accelerated milk replacer program will increase powder feeding weekly up to week 3, hold constant weeks 3, 4 and 5, and then reduce powder feeding on week 6 just before weaning.

At the University of Missouri’s Southwest Research Center dairy, calves are fed the following rates of accelerated milk replacer (7.5 ounces milk replacer in 3 pints of water/feeding week 1, 12.5 ounces milk replacer in 5 pints of water/feeding week 2, 15 ounces milk replacer in 6 pints of water/feeding on weeks 3, 4 and 5, and 10 ounces milk replacer in 4 pints of water/feeding week 6). Calves are weaned at the end of week 6 if consuming the correct amount of calf starter. In a recent trial at the Southwest Center, calves were fed either an accelerated or traditional milk replacer and weighed weekly to determine body weight and average daily gain differences (Figure 1). Preliminary results show calves fed the accelerated milk replacer consistently gained 0.2 to 0.3 pounds per day more weight than calves on the traditional milk replacer during the milk feeding period. Calves weaned at 6 weeks on the accelerated milk replacer weighed 136 pounds at weaning compared with 142 pounds for calves weaned at 8 weeks on the traditional milk replacer. Calves on the accelerated program weighed 159 at 8 weeks. Producers have started to use this management practice to wean calves earlier at similar weights compared with their more traditional program to save on labor during this time of intensified calf rearing.

Results from confinement operations suggest other benefits of accelerated milk feeding may occur as well. Research suggests a trend in increased milk production during the first lactation as well as more days in milk for a lifetime as a result of earlier breeding and calving. Results from the trial regarding milk production and age at calving at the Southwest Center are pending.

Figure 1. Average daily gain of heifer calves fed either an accelerated or a traditional milk replacer.

Mob feeding

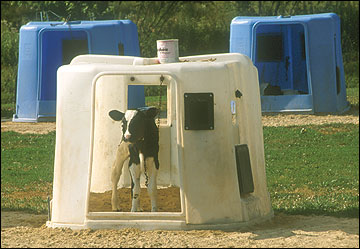

Many dairy grazing operations attempt to calve in seasonally rather than freshen year-round. Producers may calve in windows of 45 to 60 days followed by a noncalving period. This enables producers to concentrate and manage larger groups of heifers of similar age and size. However, this mass calving will require more available labor at calving and the need for more calf housing and rearing equipment (Figure 2).

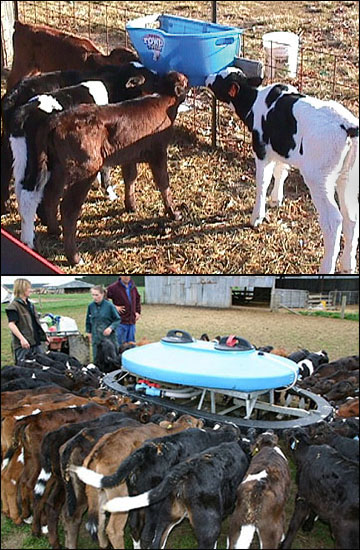

Some producers have tried to eliminate this problem by electing to “mob feed” several calves at the same time. Equipment for mob feeding consists of a tank with several specialized nipples either connected directly to a small reservoir or attached by tubes extending to the bottom of the tank (Figure 3). Nipples are designed with check valves to keep milk in the tubes or nipples if the vacuum is broken by the calf releasing the nipple. Milk is generally fed twice daily to reduce incidence of calves scouring and spoilage of the milk. Manufacturers recommend cleaning and sanitizing the equipment only after a group of calves has been weaned. Reports from New Zealand as well as Missouri indicate that scours and other illnesses are less of a problem than that of feeding individual calves.

Mob feeding requires a different management style than other methods of feeding. Producers need to maintain a program for continuous observation of each pen and each heifer for thriftiness and health condition and to determine whether certain heifers attempt to nurse other calves. Observations and experience suggest that the continuous presence of the feeding system reduces the incidence of heifers nursing other calves. This will allow the calves to have something to nurse rather than each other. When they tire of nursing, they will rest.

In a mob feeding systems, heifers should be grouped in a pen according to size, age and aggressiveness. Ideally, the calves in a group would be born within one week from first to last calf. Each mob feeder should have more nipples than calves in the pen. For example, a mob feeder with 10 nipples for a pen of eight. Feeding of the calves must be on a timely schedule, i.e. same time each day. The milk or milk replacer should be fed at 105 F. In addition, water should be continuously available because it encourages consumption of calf starter.

At least 34 to 45 square feet of clean, dry bedding should be available per calf. The ventilation system should allow for at least four air exchanges per hour.

Figure 2. Individual calf hutches enable producers to concentrate calving of large groups of heifers.

Figure 2. Individual calf hutches enable producers to concentrate calving of large groups of heifers.

Figure 3. Mob or group feeding of calves allows producers to manage large groups of similar age and sized heifers.

Figure 3. Mob or group feeding of calves allows producers to manage large groups of similar age and sized heifers.

Calf starter and hay feeding

Energy requirements in a growing calf are high. It is imperative that producers provide an energy-dense feed (dry calf starter and milk or milk replacer) to ensure that calves attain the levels of nutrition required for normal growth and rumen development. Calf starters should be highly palatable and digestible, providing 15 to 18 percent crude protein, and should be based on coarsely ground or flaked cereal grains supplemented with necessary vitamins and minerals. The incorporation of a 10 to 25 percent ground or chopped high-quality fiber source in a balanced calf starter may increase dry matter intake and weight gain when compared with unsupplemented diets. Oats are a commonly accepted fiber source because of their bulk and palatability.

The feeding of forage (hay) has been a common feeding procedure in the raising of preweaned calves. This, however, may not be the best management practice to ensure consistently vigorous calves ready for weaning at 8 to 10 weeks of age. Calves receive the majority of their energy and amino acids from milk or milk replacer. Because calves must rely on ruminal fermentation of grains and forage after weaning, a calf must have an adequately developed rumen to ensure continued growth. The feeding of grain stimulates the production of volatile fatty acids (VFAs), primarily butyrate, which is required in the development of the rumen. The feeding of hay stimulates the production of acetate, a VFA that does not contribute to rumen development. The feeding of hay, even high-quality hay, decreases the intake of energy-dense calf feeds, delays rumen function and reduces calf gain after weaning. It is widely recommended that feeding hay be delayed until calves are 8 to 12 weeks of age. A calf may be weaned when it consistently consumes 1.5 to 2.5 pounds of calf starter per day (generally three days in a row or more). Weaning should be based on calf starter intake, rate of gain and age. These factors are interrelated and should be considered in the calf rearing practices for each farm.

Role of pasture

During the first two months of life, dairy calves function primarily as monogastric (simple-stomached) animals because of inadequate rumen development. At two months of age, the calf starts functioning more like a ruminant, but the rumen is not fully developed until about nine months of age. During this developmental phase, it will be necessary to feed at least minimal amounts of grain to maintain proper growth.

The dairy literature suggests that no more than one-third of forage dry matter for heifers less than six months old should come from high-moisture forages (pasture) because of inadequate rumen development. However, in a trial at the University of Vermont, 20 Holstein and crossbred calves were reared from two days of age until weaning on pasture under management-intensive grazing. The calves grazed Kentucky bluegrass and white clover starting at a height of four inches and grazed it to a 2-inch stubble height. Calves were fed two gallons of milk per calf per day using barrels with New Zealand style nipples and 2 pounds of a 19 percent crude protein calf starter.

At weaning (about 60 days) the calves were separated by weight and breed into two groups, one of which received 2 pounds per day of 19 percent crude protein calf starter and the other 4 pounds. Both groups of heifers showed an average daily gain (ADG) of 1.5 pounds per day after weaning until the end of the grazing season. This trial would indicate that weaned heifers can show an adequate rate of gain, if 1.5 pounds ADG is acceptable, on high-quality pasture after weaning. However, to achieve this level of performance, the heifers must be fed extremely high-quality pasture (Figure 4). If this type of system is implemented, calves should be weighed at least monthly to monitor ADG as a means of evaluating the system.

Figure 4. Strip grazing is one of the best ways to provide high-quality pasture for replacement heifers.

Figure 4. Strip grazing is one of the best ways to provide high-quality pasture for replacement heifers.

Growth curves and targeted body sizes

Dairy heifers, from 400 pounds to springer, are often the most neglected animals on a dairy operation. Since they are the future producing units for the operation, it is crucial that dairy managers monitor heifer development by keeping accurate records on animal identification, age, health and breeding status, and size. It is not uncommon for heifers in Missouri to freshen at 28 to 30 months of age. This may be due to smaller than desired sizes at breeding age because of inadequate nutrition and management. Calving older heifers can potentially cost producers $1.50 in net income for each day over 24 months of age until freshening.

Some producers elect to weigh heifers at critical stages of development (weaning, 6 months, 12 months, breeding and springer) to determine the effectiveness of their heifer-rearing program. This allows the producer to adjust nutritional planes to ensure proper gain (Figure 5). Others have incorporated a less strenuous routine by measuring wither height and estimating body condition to aid them in monitoring the heifer’s progress. Regardless of the method, a management program will help producers reduce age at first freshening and attain optimum body size.

Heifers destined for confinement operations are often large-framed, with mature weights of 1,450 to 1,550 pounds for Holsteins and 900 to 1,000 pounds for Jerseys. Heifers should reach at least 55 percent of their mature size at first breeding and 80 to 85 percent of their mature size at first freshening (after calving). Thus, Holstein and Jersey heifers should weigh 800 to 850 and 500 to 550 pounds at breeding and 1,150 to 1,250 and 700 to 850 pounds at first freshening (after calving), respectively. These dairy animals need to attain these large sizes to compete in confinement operations maximizing milk production.

In contrast, many graziers prefer smaller-framed heifers. Data from New Zealand suggest that weights of 616 and 440 pounds at breeding, 902 and 704 pounds at first 24-month freshening, and a mature size of 1,026 and 828 pounds for Holstein and Jersey cattle, respectively, are ideal for grazing. Most dairy grazing operations in the United States are likely to be within these ranges, according to university studies. Managers of grazing dairies indicate the need for a moderate-sized animal to reduce maintenance levels and feed costs while still optimizing milk production and farm profitability.

Regardless of the management practice used in raising replacements, producers must evaluate whether their practice is cost-effective and viable for their operation. Common methods of obtaining or developing replacements for the dairy herd include

- Conventional feeding and use of pasture when available,

- Use of management-intensive grazing with supplemental feed when necessary,

- Custom-raised heifers, or

- Purchasing from outside sources.

As with any business or enterprise, it is imperative that producers keep accurate production and financial records on their dairy heifer practice. This allows them to make wise business decisions when evaluating other methods of obtaining replacement heifers. These records can help the manager price surplus heifers. Many grazing operations have replacement needs (cull rate) of 20 percent or less and therefore will have the opportunity to expand internally or market replacement animals. Because of this potential for surplus heifers and cows, the producer should realize the needs of his clients, whether it is for grazing or confinement operations. Confinement operations may not desire the small to moderate size cattle or the crossbreeding programs common to grazing dairies. If dairy producers are to rely on the sale of these cattle as part of their income, they must provide buyers with the type of cattle desired.

Producers should use their records to determine the costs of developing a dairy replacement heifer. This allows the producer to determine the feasibility of other practices, such as having someone else develop the heifers (custom raise) or selling heifers at birth and buying replacements as needed. Without this financial information, it is impossible to determine the most viable management option.

The use of a management-intensive grazing system for the development of dairy heifers is often the most economical practice. Research at the University of Missouri’s Southwest Research Center indicates that heifers are capable of gaining 1.7 to 1.8 pounds per day when managed in a grazing system. Heifers began the trial with initial weights of 400 pounds and ended with final weights of 1,300 pounds at freshening. Supplementation included a grain mix (75 percent soyhulls, 25 percent wheat midds plus a vitamin-mineral mix) at 0.5 percent of body weight in the spring and 0.75 percent during the winter months (Figure 6). Harvested forages were fed ad libitum during winter months. This suggests that heifers can be raised to reach optimum sizes and freshen near 24 months of age when managed properly.

However, many grazing operations elect to have other producers custom-raise their heifers to maximize the land available for lactating cows. This allows the producer to focus on the milk/dry cow programs and the grazing system while a custom grower manages the heifer enterprise. Other producers have the land available or do not elect to “farm out” their heifers because they do not wish to expand cow numbers. Smaller grazing systems can be designed for these heifers, which can be used in the lactating herd system to manage surplus forage in a put-and-take method. Still other producers have opted to sell all baby calves, heifers and bulls, and purchase replacements, as needed. These producers play the game of price fluctuations and the difficulty of purchasing the type of cattle they desire at a reasonable price. Another consideration in buying any or all replacements is the potential for bringing diseases or health problems such as Johne’s disease, BLV or mastitis into the herd. Preferably, these producers should purchase animals from known sources where the milk production, somatic cell count (SCC) and health status of the animals are known. However, these types of animals are not always available.

Figure 5. Weighing heifers at critical stages of development enables producers to gauge the effectiveness of their management program.

Figure 5. Weighing heifers at critical stages of development enables producers to gauge the effectiveness of their management program.

Figure 6. Heifers are capable of gaining 1.75 pounds a day with a well-managed MIG system that included supplementation.

Figure 6. Heifers are capable of gaining 1.75 pounds a day with a well-managed MIG system that included supplementation.

Housing

Animal housing facilities need to be properly designed and well managed if replacements are to grow well and stay healthy. Regardless of the system used, housing should have the following characteristics: adequate space, dry and draft-free conditions, fresh air, adequate bunk space and water, sanitary conditions, and the ability to group heifers by size and age.

Health program

The first few months of a calf’s life are critical for producing a healthy and productive animal. The best kind of health program is one that is preventive instead of treating symptoms. Keep accurate vaccination and health records to help prevent unnecessary death loss and ensure healthy heifers. Freeze brands, ear tags or neck chains are good identification methods to help maintain accurate records. Because producers in different areas of the state or nation face different health problems, each dairy operation should consult a local veterinarian to plan an effective preventive health program.

This publication replaces Chapter 9, Management of Replacement Heifers, in MU Extension publication M168, Dairy Grazing Manual. Original authors: Tony R. Rickard and Stacey A. Hamilton, University of Missouri. Revised 2022 Scott Poock and Stacey Hamilton.