Collection, storage and land application are major components of a complete animal manure management system to prevent water pollution. Uncontrolled runoff from cattle feedyards, hog lots, milking parlors and stockpiled poultry waste contributes significantly to high nitrate and phosphate levels in surface water and groundwater. Efficient and practical methods of runoff control are available to help protect the farmstead water supply.

Manure storage, above or below ground, is an environmentally sound management option for producers. Other benefits include improved animal health, labor savings, and more efficient meat or milk production. Efficient collection and storage can conserve the nutrient value of large volumes of manure.

Proper land application of stored manure eliminates the need for spreading on frozen ground during winter months, controls nutrient levels applied to the land, eliminates runoff and reduces liability.

This publication addresses some of the more important things to consider when evaluating sites for new animal/poultry facilities or making improvements to existing ones.

Livestock facilities

Distance from well

Place wells in an elevated area upslope of the livestock lot, confinement facility or manure storage structure so that runoff will not drain into the vicinity of the well. The Missouri well code requires a minimum separation of 100 feet between existing livestock lots and new wells. With good farmstead planning, livestock facilities would be 300 feet to 400 feet from the house. Because the well is often near the house, it is likely there would be more than 200 feet between the well and the livestock yard.

Minimum separation distances regulate new-well installations, as well as the distance from existing wells to new sources of contamination. The law requires that existing wells only meet separation requirements in effect at the time of well construction. Make every effort, however, to exceed old requirements, and strive to meet current regulations whenever possible.

Site characteristics

Groundwater protection is a major consideration in siting a livestock feedlot, thus soil characteristics are important. Important soil characteristics include surface and subsoil texture, soil depth, permeability and drainage class. The best site has a deep, well-drained silt loam/clay loam soil with low permeability. A poor site has shallow soil, or a high-water table, or a sandy/gravelly soil with excessive drainage and high permeability.

For existing open lots on poor sites, the best options for protecting groundwater might be eliminating the lot and using total confinement for the livestock or providing paved lots and liquid-tight basins to store lot runoff.

Clean-water diversion

One way to reduce water pollution from livestock lots is to reduce the amount of clean water entering the lot. In all cases, maintain diversion structures.

Some methods and practices for diversions include these measures:

- Waterways, small terraces and roof gutters to direct water away from livestock yards.

- You can construct an earthen ridge or terrace across the slope upgrade from a livestock lot to prevent runoff from entering the yard.

- In some areas, if a diversion terrace is not practical, a catch basin with a tile outlet could be installed above the livestock lot.

Runoff-control systems

A livestock lot without a runoff-control system typically has an earthen surface compacted by animal traffic. This surface is not shaped for water drainage, so it is sometimes dry and sometimes muddy. Manure typically accumulates on the surface, and decaying manure is mixed into the soil by animal traffic.

Water running off concrete pads located near barn doors or feed bunks and clean water from roofs and upslope areas can flush manure from the yard and create mudholes.

This type of lot is difficult to manage, and the absence of runoff controls may lead to water quality problems. Contaminated runoff from an active feedlot that accumulates in areas adjacent to the lot may flow through the soil and threaten groundwater quality. This risk is particularly high on sites with high infiltration and percolation rates, such as sandy soils and other soils with good-to-moderate drainage.

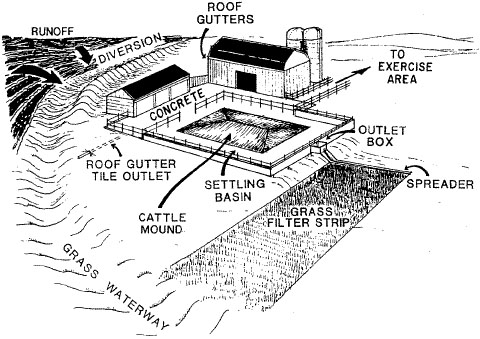

Runoff-control systems can remedy such problem situations. These systems collect livestock-lot runoff, settle out manure solids and direct the remaining water to open fields or filter strips, away from streams, ditches, waterways and areas of permeable soils and creviced bedrock. Another option is to collect and store runoff for later land application. Figure 1 shows a typical livestock-yard runoff-control system.

Figure 1

Figure 1

Typical livestock-lot runoff-management system. Adapted from Barnyard Runoff Management, Wisconsin Department of Natural Resources and Department of Agriculture, Trade and Consumer Protection, 1987. Adapted by Leonard Massie, with graphic assistance by Andy Hopfensperger, University of Wisconsin-Madison, Department of Agricultural Engineering.

Lot cleaning or scraping

Clean livestock lots regularly. The amount of manure on a livestock lot depends on the number of animals and the hours per day animals spend on the lot. Cleaning and scraping at least once a week is preferable. Heavy concentrations of animals may require solids removal more often. Concrete surfaces are easier to clean than earthen lots. Earthen yards are cleaned when dry, so solids may be removed less frequently.

Concentration of animals and type of feedlot surface

The area needed per animal to minimize the risk of groundwater contamination depends on the type of lot surface. The amount of concrete surface area needed is much less than that required for an earthen lot.

The concrete area needed is a balance between traffic on the lot and resting area provided for animals. Too large an area results in manure freezing to the surface for long periods although too small an area will result in animals having difficulty moving about.

For dairy operations, the best protection for groundwater is to confine animals to a freestall barn or roofed lot. Where a lot is needed, 75 square feet of fenced concrete per cow is recommended (400 square feet of earthen surface) and roughly 2,000 square feet of exercise area, if one is used. Carefully direct runoff water from the concrete onto the earthen area. Curbs will keep runoff from flowing off the edges of the concrete area.

Lot management involves considerations other than surface-water and groundwater protection. A combination of lot surfaces can offer the most flexibility in adapting to weather conditions. You may choose livestock location based on the amount of mud in the lot: on concrete in sloppy conditions, on an earthen surface in dry weather and on a mound in intermediate conditions.

The type of surface also affects management. Earthen lots, for example, might be cleaned only once or twice a year.

If bedrock is close to the surface where your livestock lot is located, pave the surface with concrete, or totally confine livestock.

Studies have found little nitrate in the soil of active feedlots. With active feedlots, the subsurface soil is generally packed tightly, forming a layer though which water moves slowly. A mixed layer of manure and soil placed on top of the compacted subsurface soil will have minimal nitrate and bacteria leaching.

Abandoned feedlots

Abandoned feedlots can pose a particular groundwater-contamination risk. As the manure and soil mixture breaks down, from lack of use and weather conditions, the potential increases for nitrogen-rich water to leach through and reach the groundwater.

If you have a permanently abandoned lot, dig it up, spread the manure and soil mixture on fields and refill the former lot with other material or soil. Another option is to plant a high-nitrogen-using crop that will use the nitrogen released by the manure soil decomposition process. Remove any manure from the lot that will not be used within a short period of time. Otherwise, cracks may develop in the surface and allow leaching of nitrates.

Animal manure storage

Long-term storage

Livestock manure can be stored either in solid, semisolid or liquid states.

- Solid facilities use walls and slabs for stacking of heavily bedded manure.

- Semisolid facilities use pumps to move manure into containment areas and may separate solids from liquids.

Liquid facilities hold manure in tanks, concrete or earthen pits or anaerobic lagoons.

Liquid and semisolid storage systems are self-contained. Groundwater contamination can occur if the facility is not structurally sound and allows waste materials to seep into the soil. A threat to surface water exists if pits or lagoons are allowed to overflow. Liquid storage systems require the use of pumps and pipes for moving wastes from the barn to the storage structure. These must be carefully installed and maintained to ensure that they do not leak.

Each time they are emptied, carefully check steel and concrete structures for cracks or the loss of watertight seals. If any breaks are apparent, repair them immediately. Likewise, check the bottom and side slopes of earthen waste-storage structures to be certain that liner materials have not been eroded away by pit agitation.

After a period of years, freezing and thawing as well as wetting and drying may cause the sidewalls of earthen pits to crack and erode, allowing manure to seep into the underlying soil or subsurface geologic material. Earthworm channels also allow wastewater to move through the liner. Groundwater contamination will result if the subsurface materials do not have sufficient ability to break down contaminants contained in the leachate. Evidence suggests that the design life for earthen structures is probably 10 years to 30 years.

It is not easy to recognize seepage from in-ground waste-storage facilities. The absence of liquid within a storage pit that requires yearly pumping may be the only indication of a leaking in-ground storage lagoon.

Some facilities for storage of solid or semisolid manure are designed to allow seepage from the manure stack. In these instances, the design must include storage and treatment facilities for the waste that seeps out. If conditions allow, structures such as settling basins or terraces can be used to hold back solids, and concrete or earthen storage basins can be used to store the liquid runoff. Don't consider these systems on sites with coarse-textured soils, creviced bedrock or shallow water tables.

The best way to handle seepage is to channel it into a watertight holding pond or storage tank. In those areas where sufficient soil is unavailable for the construction of filter strips, or where the construction of a holding pond is not feasible, another option is to build a roof over the structure to eliminate additional water being added to the manure stack. Roofed storage systems require adequate bedding to absorb and retain the liquid portion of the manure.

Short-term storage

Short-term storage, usually 60 to 90 days, is an important option for farmers. It allows them to hold livestock manure during periods when daily spreading may not be feasible. Short-term storage is restricted mainly to solid manure and has the disadvantage of having to handle the manure twice. Designs are available for structures for short-term storage that facilitate handling and provide effective protection for surface water and groundwater.

Many farmers scrape manure into piles in the livestock lot rather than haul it during bad weather or busy work periods. This practice is not recommended because of possible herd health problems and water quality problems. The severity of those problems depends on characteristics of the livestock yard area where the manure is piled and the area to which runoff flows. Regulations governing milk production do not allow milking cows to come in contact with stacked manure.

Many farmers have open housing for young stock, such as pole sheds, where manure is allowed to accumulate for extended periods of time. Roofs on these structures keep rain and snow off the manure. These structures are relatively safe for water quality if they are protected from surface-water runoff and if adequate bedding is provided to absorb liquids in the manure. To minimize water quality problems, provide adequate bedding to reduce seepage and clean these sheds as frequently as possible.

Manure storage location

The location of livestock manure storage in relation to any well is an important factor in protecting the farm water supply. For most livestock manure facilities, the minimum separation distance is 100 feet; 300 feet is preferred, as defined in Missouri Revised Statues, Missouri Private Well Construction Standards (RSMo 256.600).

Observing these separation distances and placing manure-storage facilities downslope from wells is important for protecting your water supply. For more information about separation distances and how the condition of your well might affect the potential for contamination, see MU publication EQ675, Reducing the Risk of Groundwater Contamination by Improving Drinking-Water Well Conditions.

Observing these minimum distances may help protect your own well, but poorly designed or poorly maintained livestock manure storage facilities still could contaminate the groundwater that supplies other local drinking-water wells. Protecting the groundwater resource as a whole can help protect your neighbors' wells, as well as possible drinking-water supplies for future generations.

Depth to seasonal high-water table or fractured bedrock, along with soil type at the waste-storage location, is another important factor. Depth to water table sometimes is available in the county soil survey, but this varies from county to county. You can request this information from the Missouri Department of Natural Resources (DNR), Geological Survey Division, P.O. Box 250, Rolla, Mo. 64501, 573-368-2165 or 800-361-4827.

Abandoned manure storage structures

Abandoned manure storage pits, especially earthen ones, can pose significant water quality problems. Any abandoned structure should be completely emptied. In the case of earthen manure-storage facilities, liner materials (to a depth of about two feet) should be removed and spread over croplands. The remaining hole should be filled and leveled. Manure packs from pole sheds no longer in use also should be removed and the manure land-applied. If manure is stacked in fields, remove it as soon as conditions permit. Check with the DNR, your county MU Extension office or the Missouri Natural Resources Conservation Service for information on closure of livestock facilities. You also can refer to the closure regulation, Missouri Code of State Regulations, Rules of the Department of Natural Resources (10 CSR 20-6.015, Section 12) for specifics on livestock manure facility closure.

Milking-center wastewater storage

Wastewater from the dairy milking center, including wastes from the milking parlor (manure, feed solids, hoof dirt) and from the milkhouse (bulk tank-rinse water and detergent used in cleaning) commonly is disposed of by channeling the waste to a livestock waste management system. The material may be pretreated in an aerobic lagoon before it enters the livestock-waste storage facility. Human waste from the milking center may be mixed with livestock waste if it receives the equivalent of secondary treatment, as in an aerobic lagoon or aerated septic tank, before it enters the system managing animal manure. This is allowed under a memorandum of understanding between the DNR and the State Milk Board.

Delivery of milking-center wastewater to a manure-storage facility, if available, makes the most sense environmentally. Discharge options are:

- Field application

- Overland flow

- Slow surface infiltration

Your drinking water is least likely to be contaminated if you follow appropriate management procedures or dispose of wastewater in any location off the farm site. However, proper off-site disposal practices are essential to avoid risking contamination that could affect the water supplies and health of others.

No discharge by combining wastes

Milking-center wastes and manure can be combined as liquid manure and stored in a properly constructed storage facility to provide additional flexibility of storing wastes until they can be applied at the right time to the right sites (Figure 2).

This option is limited to farmers who handle their manure in slurry form. Although it adds to transportation and spreading costs, nutrients from dairy wastewater can be used to meet crop requirements, thus reducing fertilizer costs.

Apply milking-center wastes with manure to fields at rates that do not exceed crop needs for nitrogen. Take care, however, to keep soil phosphorus levels from accumulating to levels that will harm crops.

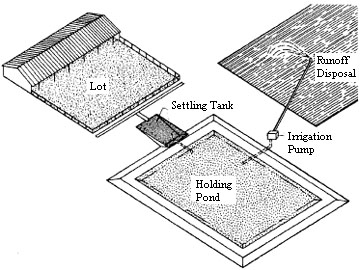

Milking-center wastewater combined with seepage from solid-manure storage or livestock lot runoff can be stored in a holding pond (Figure 3). You can apply the contents of the pond to fields when conditions are appropriate.

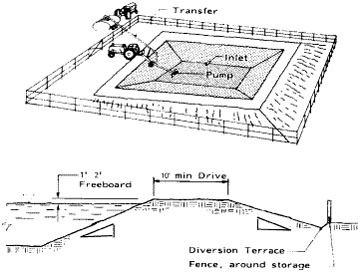

Figure 2

Figure 2

Earth basins for manure and dairy wastewater storage. Source: Dairy Housing and Equipment Handbook, Midwest Plan Service, Ames, Iowa.

Figure 3

Figure 3

Detention pond for storage of dairy wastewater and livestock-lot runoff. Source: Dairy Housing and Equipment Handbook, Midwest Plan Service, Ames, Iowa.

Treatment before discharge

Pretreatment is mandatory if human waste from the center is to be added to the livestock-waste management system. The septic tank provides a place for bacteria to decompose some wastes before they enter the waste-storage facility. This process causes a scum to form on top of the water in the septic tank. Removing the scum layer every few weeks can keep the system operating more efficiently. Solids should be cleaned from the tank every few months to avoid sludge build-up and to prevent wastes from backing up into the milking center.

Removing solids before washing into a settling tank requires extra effort, but it reduces the rate of solids accumulation, which can extend the period between tank cleanouts.

Passing wastewater through a shallow treatment pond, also called a facultative lagoon, results in a more thorough pretreatment. Algae growing in the pond generate oxygen, which can help decompose organic compounds without obnoxious odors.

Solids that settle to the bottom of the pond usually decompose in the absence of oxygen. To prevent groundwater contamination, such ponds must be built of an impervious material, such as packed clay, concrete or synthetic liner.

If human waste is not included in the milkhouse waste, the wastewater can be discharged directly into a lagoon without first going through a settling tank.

Land application of animal manure

Land application is the predominant method of dispersing animal manure. Solid or slurry manure is applied with hauling equipment. Liquid manure (lagoon effluent) is land-applied by irrigation. When properly managed, land application allows for safe use of animal manure and beneficial use of the nutrients and water by vegetation. Apply both solid and liquid wastes to land using rates and methods that prevent surface runoff of pollutants and leaching of pollutants to groundwater.

Methods

The amount of manure applied to the land surface is determined by a soil analysis and a plan for how crops would use the manure. Application rates should not exceed the nutrient or moisture needs of the plants growing or to be grown at the site, and applied nutrients should be credited in the fertilizer program for the site.

Separation distances

The Missouri DNR has established required and recommended guidelines for separation distances for systems of livestock manure management. These separation distances apply to both waste-storage structures, such as lagoons, and to the areas on which manure is land-applied.

Special circumstances may dictate that separation distances be greater than shown, and these are evaluated on a case-by-case basis.

Silage storage

Silo design and construction

Silo construction for most agricultural uses is not regulated in Missouri. Most silos built today have interiors made of concrete or, in the case of oxygen-limiting silos, a glass-like coating over steel. Silage stored in glass-lined silos typically has a lower moisture content and poses a low risk of groundwater contamination. It is possible, though, for some liquid to leak out.

Silo bags generally store silage of higher moisture content. Liquid can pool in the bag and leak out when it is opened.

Horizontal trench silos excavated into the ground may affect groundwater, especially in coarse soils and sites close to the water table. Properly compacted clay soils and concrete floors can limit leachate seepage.

The type of silo on your farm often has less effect on its potential to contaminate groundwater than the condition of the silo. For example, an old wooden silo with an earthen floor poses a higher risk than a concrete horizontal silo with a concrete floor (Figure 2). Older structures can be relined to make them relatively watertight.

Silo caps or covers keep rainwater from entering the silage. This preserves a quality silage and reduces the potential for producing leachate. Horizontal or trench silos should be covered with a plastic sheet. Tires can be used to keep the cover in place.

It is important to divert clean water away from new and existing silage-storage structures. For both vertical and horizontal silos, diverting clean water away from silage can protect both groundwater and surface water.

Farmers can use several methods to reduce leachate production from silage. The most effective is allowing the material to wilt in the field for 24 hours. Although this may not be possible in humid conditions, it can reduce moisture content by 10 percent and leachate production by 85 percent. Other methods include varying cutting and harvesting times, cutting or crimping the materials or adding moisture-absorbent materials to the silage as it is stored.

Adding absorbent materials not only reduces leachate, but it also raises the nutrient value of the silage. Materials to use include oatmeal, dried sugar-beet pulp, dried corn cobs, ground corn, newsprint and bentonite clay. Most of these materials will absorb from one time to three times their weight in water, and, to be effective, enough must be added to absorb the anticipated leachate.

Silo location

To prevent possible well contamination, place silos as far away from wells as practical. Keep plastic storage tubes and new glass-lined silos at least 75 feet away from a well. Silos with a pit, or without a pit but with a concrete floor and drain, must be at least 100 feet from a well. Earthen trenches or pits must be at least 100 feet away from a well.

Minimum separation distances regulate new-well installations. Existing wells only are required by law to meet separation requirements in effect at the time of well construction. Make every effort, however, to exceed "old requirements," and strive to meet current regulations whenever possible.

Leachate collection and disposal

Leachate can be collected from tower and horizontal silos by channeling the liquid into a water-retention structure, usually a pond lined with concrete, clay or plastic. Drain tiles around tower silos can be used to collect any seepage from the silo.

Horizontal silos use channels to direct seepage into a collection area. Contact your local MU Extension center for help with design.

The most cost-effective disposal method is land spreading. Nitrogen in leachate has significant fertilizer value if applied during spring or early summer.

Because of its high organic content, leachate can burn grasses and remove oxygen from the soil. Farmers who consider land spreading should consult an agronomy specialist to determine how much leachate can be safely spread on each field.

Other management factors

Missouri has enacted legislation to regulate livestock manure discharge. All concentrated livestock facilities must have a waste-management system. Larger producers and producers who have been cited by Missouri DNR must have a permit to construct and operate a facility. Currently, confined-feedlot regulations are being revised by DNR.

If animal manure storage causes any significant water contamination, the DNR can issue a notice of discharge, which may require corrective measures. Your county Farm Services Agency (FSA) office may provide cost-share funds for the construction of livestock manure management facilities.

An acceptable farmstead assessment ranking does not necessarily guarantee regulatory compliance.

Resources

- For design assistance and information about technical standards for runoff-control systems, structures for animal manure storage, silo construction and milking-center wastewater storage, contact your local MU Extension office, local Natural Resources Conservation Service (NRCS) office or a qualified engineering consultant.

- For information on designing wastewater treatment systems, contact consulting engineers, your local MU Extension office, your local NRCS office or the MU Agricultural Engineering program at 573-882-2731.

- Financial assistance for animal manure management practices, including waste storage, may be available as part of a priority watershed plan, through the Agricultural Conservation Program administered by the U.S. Department of Agriculture Farm Service Agency. Contact your local MU Extension office or NRCS for more information.

- Missouri Code of State Regulations, Title 10, Department of Natural Resources, Division 20.

- Missouri DNR Guidelines 10 CSR 20.8020, 10 CSR20-6.015, and Animal Waste Management Manual 121 contain permit information, design standards and accepted animal manure management practices for large-animal feeding operations. Contact the Water Protection Program, Missouri DNR, 800-361-4827 or 573-751-1300.

- Private well construction standards are detailed in Missouri Revised Statues, Missouri Private Well Construction Standards (RSMo 256.600).

- To check that sanitation and water quality regulations are being met for dairies, contact your local dairy inspector and regional DNR office:

- Kansas City

816-251-0700 - Northeast (Macon)

660-385-8000 - Southeast (Poplar Bluff)

573-840-9750 - Southwest (Springfield)

417-891-4300 - St. Louis

314-416-2960

- Kansas City

Farm•A•Syst: Farmstead Assessment System Fact Sheet: This guide, previously named MU publication WQ681 Reducing the Risk of Groundwater Contamination by Improving Animal Manure Management, was originally produced as part of the Missouri Farmstead Assessment System — a cooperative project of MU Extension; MU College of Agriculture, Food and Natural Resources; and the Natural Resources Conservation Service — and was adapted from Wisconsin and Minnesota prototype versions of Farm•A•Syst.